.....

x

L.

....

RIGHT

a

FIGURE 11

-

7

-

-

K662

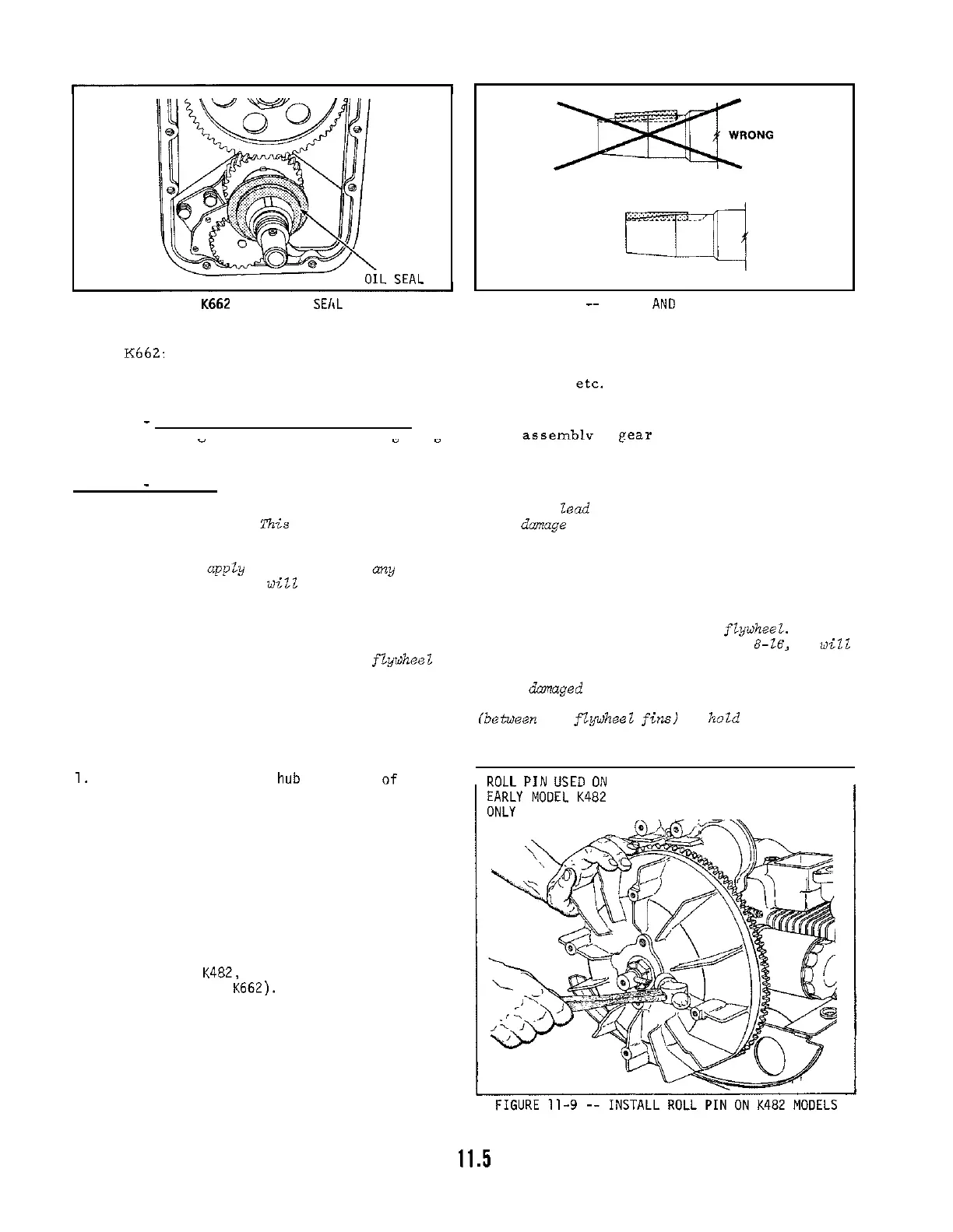

FRONT OIL SEhL INSTALLATION FIGURE 11

-

8

--

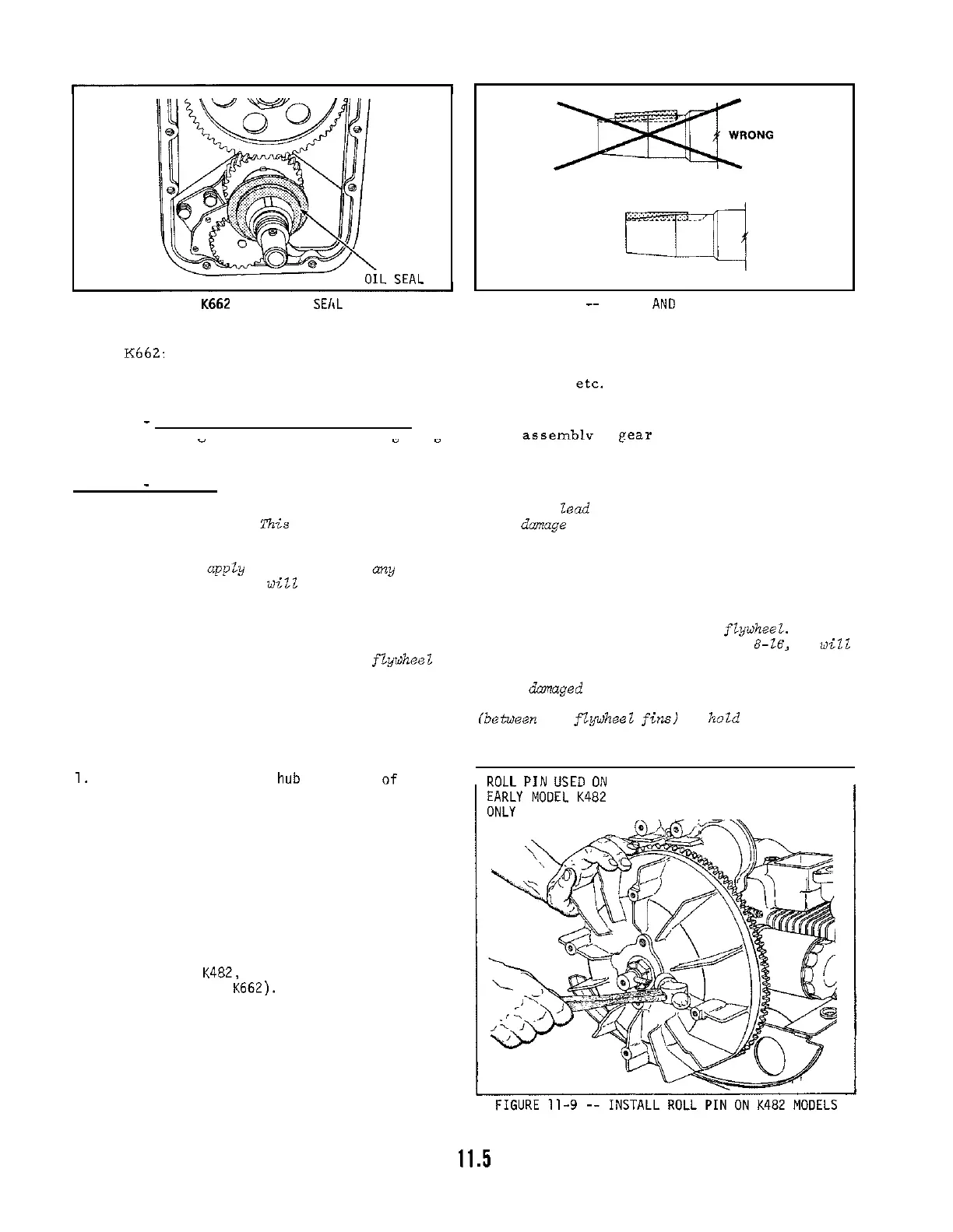

RIGHT AN0 WRONG WAY TO INSTALL

FLYWHEEL KEY

K662:

Slide oil seal unit into position with seal slot aligned with crank gear key.

Place new gas

-

ket on gear cover then position cover. Install blower housing support plate, (plus starter

or generator brackets when used) then secure cover

etc. to block with cover capscrews

and lock washers.

STEP

9

-

Alternator Stator or Magneto Coil:

On engines with alternator system or with flywheel mag

-

-

neto ienition. secure stator rine or ienition coil assemblv to eear cover. Affix leads so that

-

-

"

,

-

they will be accessible after flywheel is installed.

STEP

10

-

Flywheel

WARNING:

Improper procedures for installation of flywheels can lead to cracked flywheels and broken

crankshafts.

Z"nis not only results in extensive dmnage to an engine but presents a serious

threat to the safety of persons close to the engine.

DO

NOT

appZy grease, oil, or my lubricant to the taper of the crankshaft or hub of the fly

-

wheel, as this wiZZ cause excessive stress and possible cracking of the flywheel while

tightening.

DO

NOT

allow the key to be pushed inward on the keyway while installing the flywheez.

If the

key rides up on the rounded surface at the end of the keyway as shown in Figure

8-16,

it

will

act as a wedge and crack the flywheel hub.

DO NOT

reuse a flywheel if

it

has been dropped or damaged in any way.

DO

NOT

use a steel

bar

or any other object (beween the flywheeZ fins) to hoZd the flywheel

when the flywheel nut is being torqued, as this practice could break or crack flywheel fins

1. Make sure the flywheel hub and taper of the

I

Rnl

I

PIN

~ISF~

nN

I

crankshaft are clean, dry and completely free

of any lubricant, before installing flywheel.

2.

Position key properly in keyway as shown in

Figure 11

-

8 and carefully guide key slot in

flywheel hub over the key (if generator belt

pulley is used, install belt before placing

flywheel on shaft).

3.

Install lock nut or retaining nut and locking

tab. Hold flywheel with a strap wrench, and

tighten nut to its proper torque value (115

ft.

lbs. for

K482, K532

and

K582

models and

130

ft.

lbs. for

K662).

4.

Bend lock tabs (if used) over flywheel nut.

Drive roll pin back into crankshaft (see

Figure 11

-

9) or install crank pin and lock

in position with set screw.

Loading...

Loading...