Maintenance Operation and Maintenance Manual

Lubricants and operating fluids

The test methods and limit values reveals the result of a single coolant sample analysis as

abnormal.

Kohler Co. recommends to perform coolant analysis of used coolant for the following minimal

parameters.

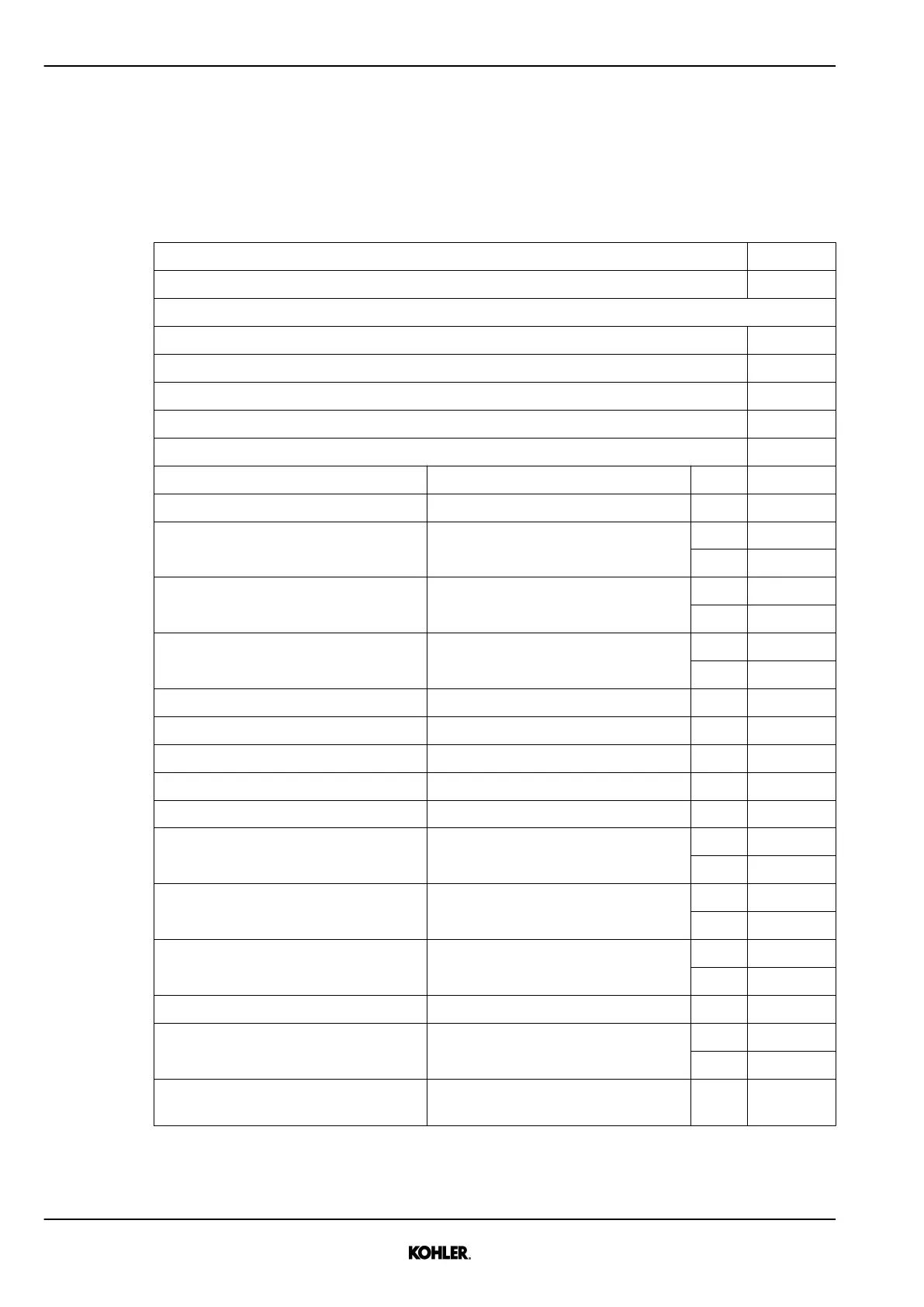

Control parameters for the coolant:

Product name

Lab-No

General information

Date of sample

Last fluid exchange

Added fluid during use

Hours of use

Machine operating hours

Analyse Method Unit

Optical appearance

Elements Additives (Ca, Mg, Si, B, P,

Ba, S, Na, K)

DIN 51399-1:2012-5 mg/kg

ppm

Elements wear (Fe, Cr, Cu, Sn, Al, Ni,

Pb, Mo, Mg, Ti, V)

DIN 51399-1:2012-5 mg/kg

ppm

Contamination (Si, Ca, Mg, Zn, Sn,

Mo)

DIN 51399-1:2012-5 mg/kg

ppm

Color Visual

Glycol DIN 51375-1, GC-Headspace, FTIR %

Corrosion Cu EN ISO 2160

Corrosion steel ISO 7120

Bacteria Dipslide test MERK count

Water hardness EN ISO 11885 mmol/l

ppm

Nitrate EN 12014 mg/kg

ppm

Nitrite EN 12014 mg/kg

ppm

Ph-value EN ISO 10523:2012-04

Pour point freezing point ISO 3016, ASTM 5985 °C

°F

* compared to fresh fluid

n.s. - not specified

Tab. 36: Coolant operational monitoring parameters

132

© 2018 by Kohler Co. All rights reserved.

KD83V16 33521030601_0_1 EN_US

2018-07

Loading...

Loading...