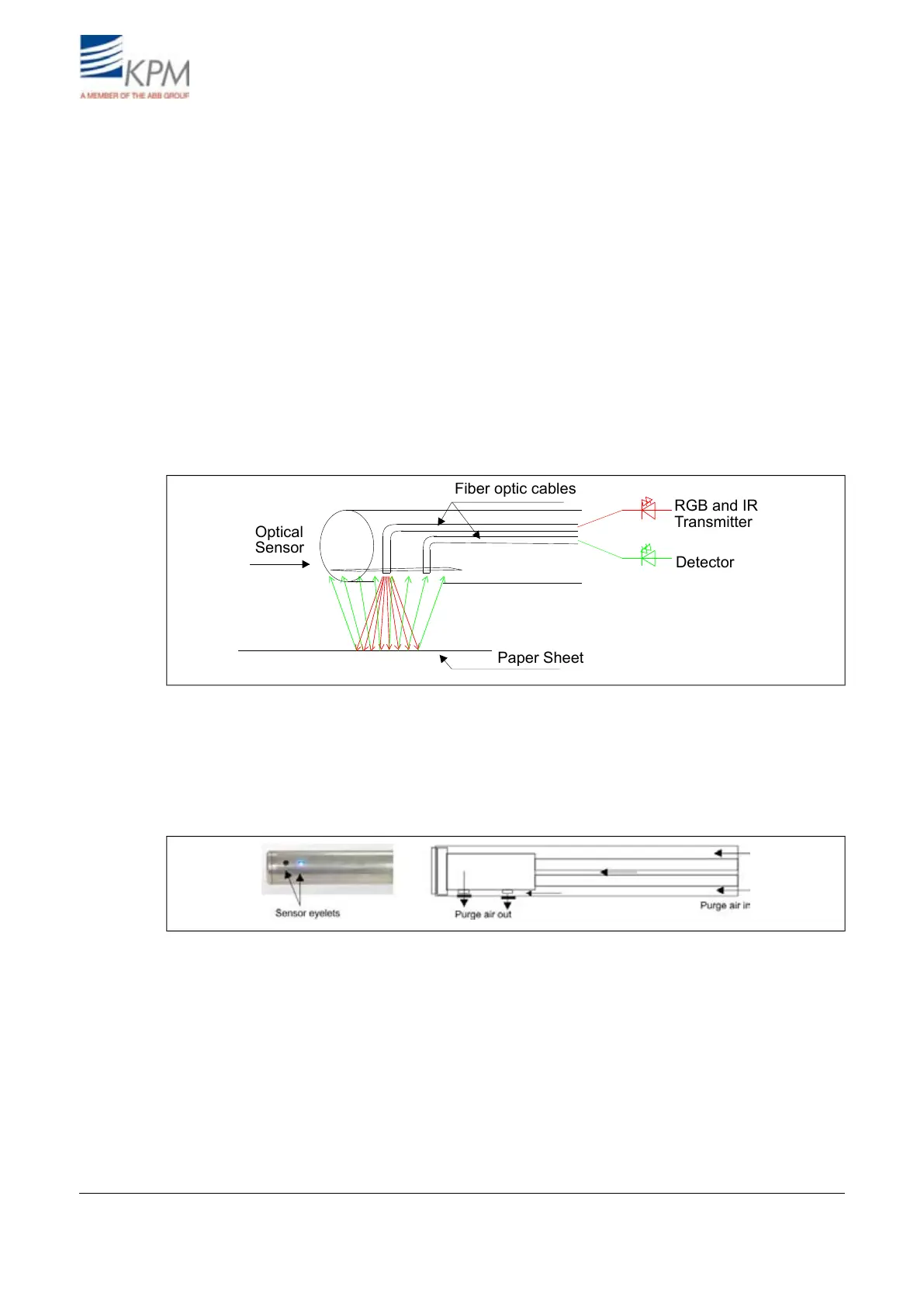

1.2. Operating principle

The KB operates on a proven, non-contact reflection principle. The light source can be either RGB

LED (red, green, blue) or IR LED (infrared). The optical sensor is placed above or under the web.

Applications include paper or board webs, wires or felts. Thanks to the unique RGB detection

method the color of the product or the felt has no effect on the measurement reliability. The sensor

is neither affected by dirt, steam nor temperatures up to 180 °C (356 °F) when installed according

to Kajaani Process Measurements specifications. There are no electronic components located in the

sensor head.

The optical sensor is connected through a fiber-optic cable to the RGB/IR light source located in the

display unit. The RGB/IR LEDs emit pulsed red, green, blue, or IR light onto the web surface. The

reflected light is received and transmitted through the fiber-optic cable to the detector. All light

components are analyzed fast for a reliable break detection.

A break activates a relay, which can be connected to the logic control of a paper machine. The reflected

light intensities are also available as optional 4 - 20 mA analog outputs.

Optical

Sensor

RGB and IR

Transmitter

Detector

Fiber optic cables

Paper Sheet

Fig. 1.2. Operating principle.

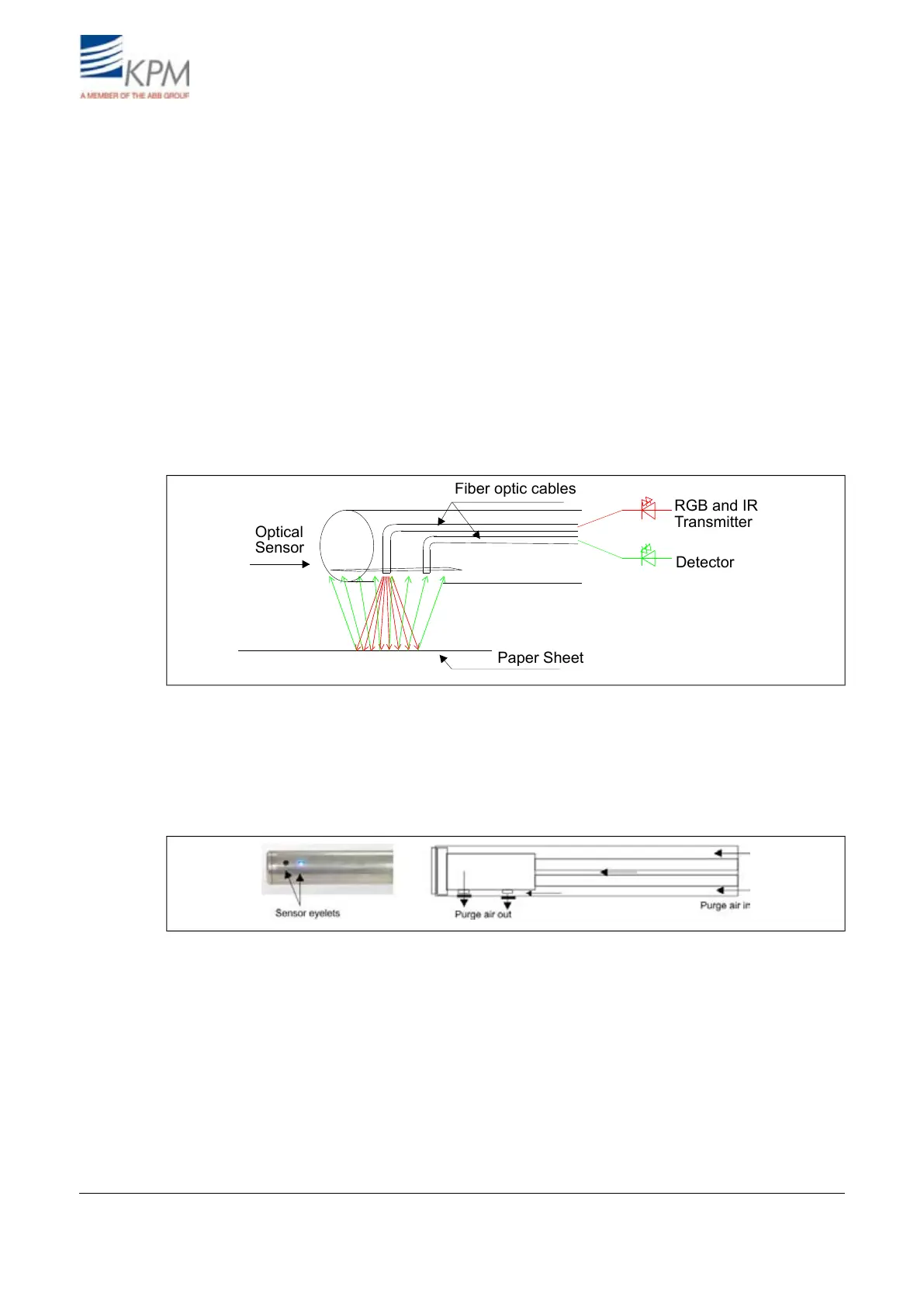

The self-cleaning sensor head is a 33.7 x 1500 mm (1" x 59") stainless steel tube with two holes

serving as eyelets for the fiber-optics and outlets for purge air. Continuous airflow through the

stainless steel enclosure keeps positive pressure around the sensor head's eyes and keeps the eyelets

free of steam, dust or debris. The openings should be located towards the surface being monitored.

Fig. 1.3. Sensor eylets and purge air operation.

KB² Man W41100099V1.24August 2012

Loading...

Loading...