Do you have a question about the KROHNE OPTIMASS Series and is the answer not in the manual?

General installation guidelines and mounting principles for mass flow meters.

Safe lifting and handling procedures for the meter.

Guidelines for flange tightening and pipe end loads.

Specifies temperature limits for operation of the meter.

Information for PED compliance in Europe regarding meter materials.

Details on secondary containment pressure ratings for the 7000 series.

Explains pressure limits based on temperature for various materials.

Installation guidelines for hygienic environments and materials.

Methods and guidelines for meter heating and insulation.

Features and usage of purge ports and burst disks.

Specifications like flow rates, tube materials, and construction.

Physical size and weight information for the meter.

Mounting instructions specific to Z-shaped meters.

Operational temperature limits for the 3000 series.

PED compliance information for the 3000 series.

Containment pressure limits for the 3000 series.

Pressure de-rating curves for SS and Hastelloy tubes.

Heating and insulation for the 3000 series.

Technical specifications for the 3000 series.

Physical dimensions for the 3000 series.

Installation requirements for twin U-tube meters.

Operational temperature limits for 8000/9000 series.

PED compliance for 8000/9000 series.

Secondary containment details for 8000/9000 series.

Pressure de-rating tables for measuring tubes.

Hygienic installation for 8000/9000 series.

Heating and insulation for 8000/9000 series.

Purge ports and burst disks for 8000/9000 series.

Technical specifications for 8000/9000 series.

Weights for 8000/9000 series.

Cable routing and connection guidelines.

How to connect the device to power supply.

Wiring diagram for MFC050 power supply.

Wiring diagram for MFC051 Non Ex power supply.

Wiring diagram for MFC051 Ex power supply.

Connecting remote sensor and converter.

Safety guidelines for hazardous area installations.

Details on MFC 050 I/O options.

Details on MFC051 I/O options.

Instructions for converter mounting conversion.

Detailed technical data for MFC050.

Detailed technical data for MFC051.

Initial device settings and behavior.

Steps for powering up and initial self-test.

Procedure for zero point calibration.

How to program using a magnet.

Description of controls and display.

Overview of the menu structure.

Explanation of keypad operations.

Steps to access programming mode.

Steps to exit programming mode.

List of functions and their settings.

Resetting totalizers and handling status messages.

Overview of initial setup functions.

Detailed procedure for zero point adjustment.

How to set standby or stop modes.

Steps for density calibration.

Procedure for testing the LCD display.

Testing current output signals.

How to test pulse output.

How to test frequency output.

How to test the alarm output.

How to test the control input.

Viewing sensor diagnostic data.

Checking hardware and software versions.

Setting the low flow cut-off threshold.

Adjusting the time constant for measurement filtering.

Selecting the flow direction mode.

Setting the flow measurement direction.

Inputting pipe diameter for velocity calculation.

Configuring an additional totalizer.

Selecting which error messages to display.

Configuring the display cycling behavior.

Setting units and resolution for mass flow display.

Setting units for the mass totalizer.

Selecting units for volume flow.

Setting velocity units.

Selecting the display language.

Selecting the density measurement mode.

Managing configuration passwords.

Password settings for custody transfer.

Configuring totalizer reset behavior.

Configuring current output 1.

Allocating functions to current output.

Setting the measurement range for current output.

Configuring pulse/frequency output.

Configuring the alarm output function.

Setting functions via external input.

Setting up instrument functions based on process conditions.

Calibrating current outputs.

Viewing sensor data.

Displaying the meter type.

Displaying the meter size.

Displaying measuring tube material.

Displaying component serial numbers.

Overview of diagnostic functions.

Explaining error codes and messages.

Troubleshooting by performing functional tests.

Common issues and solutions related to zero point.

Diagnosing driver or sensor coil issues.

Procedures for replacing electronics.

Steps to replace the front end electronics.

Steps to replace the back end electronics.

List of available spare parts.

Listing compliance standards.

Mechanical standards.

Electrical standards.

CE conformity declaration.

Pressure Equipment Directive certificate.

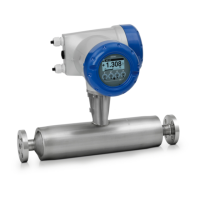

| Housing Material | Aluminum, stainless steel |

|---|---|

| Measurement Principle | Coriolis |

| Flow Measurement | Mass flow, density, temperature |

| Accuracy | ±0.1% of rate |

| Repeatability | ±0.05% of rate |

| Pressure Range | Up to 400 bar |

| Communication Protocols | HART, PROFIBUS DP/PA, Modbus, Foundation Fieldbus |

| Materials | Stainless steel, Hastelloy |

| Approvals | ATEX, IECEx |

| Output Signals | 4-20 mA, pulse, frequency |

| Protection Class | IP67 |

| Process Connection | Flanged, threaded, sanitary |

| Power Supply | 24 V DC, 100-240 V AC |

Loading...

Loading...