Fig. 11: Filter in the piping

1 Differential pressure gauge 2 Filter

NOTE

Use a filter with laid-in wire mesh (mesh width 0.5 mm, wire diameter 0.25 mm) of

corrosion-resistant material.

Use a filter three times the diameter of the piping.

Conical filters have proved suitable.

4. Connect the pump nozzles to the piping.

CAUTION

Aggressive flushing and pickling agents

Damage to the pump!

▷ Match the cleaning operation mode and duration for flushing and pickling

service to the casing and seal materials used.

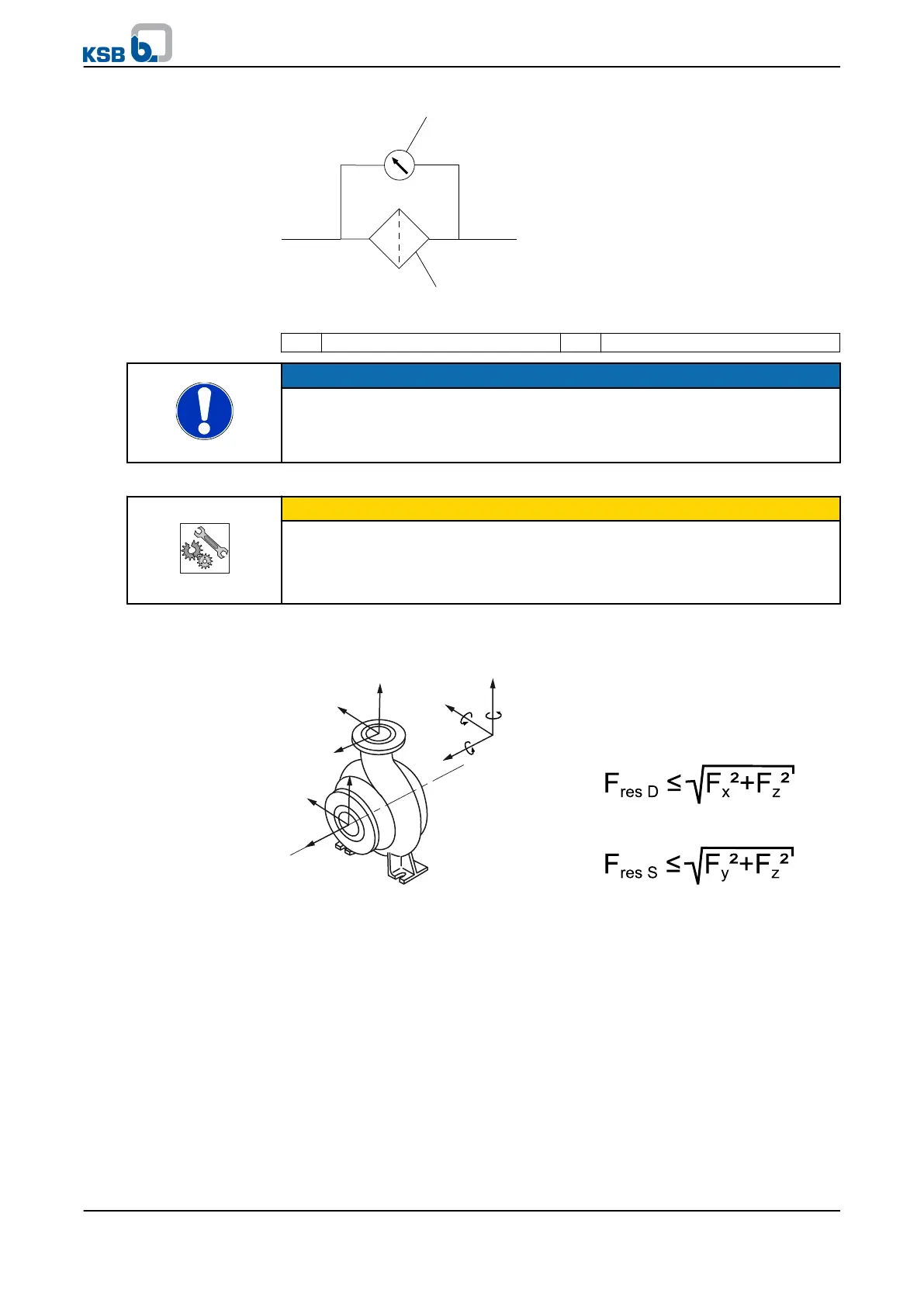

5.4.2 Permissible forces and moments at the pump nozzles

[+]

F

y

F

z

F

x

F

x

F

z

F

y

F

x

F

z

F

y

M

y

M

z

M

x

Forces and moments at the pump nozzles

The resulting permissible forces have

been determined according to the

following formulas:

The data on forces and moments apply to static pipelines only. If the limits are

exceeded, they must be checked and verified.

If a computerised strength analysis is required, please contact KSB!

The values are only applicable if the pump is installed on a completely grouted

baseplate and bolted to a rigid and level foundation.

The forces and moments were determined on the basis of API 610 (6th edition), table

2, values doubled.

Correction coefficients depending on material and temperature (see diagram below).

5 Installation at Site

KWP

25 of 78

Loading...

Loading...