Caution

Omega

18

8.2.1 Mechanical Seal ”Type H7N4”

(Shaft unit d

w

40 to 80 mm)

The mechanical seal type H 7 N 4 used is a single--acting, bi--ro-

tational, non--balanced seal which does not require circulation

pipework in cold water applications, due to the pump design.

Dry--running of the seal must be avoided at

all costs!

Installation

For the installation of the total seal assembly (mechanical seal,

seal housing) see operating i nstructions for the pump.

The shaft protection sleeves and also the surfaces of the casing

are subjected to accurate finishing processes with regard to the

O --ring seats, in order to achieve a complete and reliable seal.

Care must be taken during installation to keep these parts ab-

solutely clean, to avoid the surfaces from being damaged and

prevent entry of foreign particles.

The seat ring (8) together with the relevant O--ring (9), is fitted

into the seal cover (see general drawing). The O--ring can be

lubricated for easy sliding movement. Special attention must be

given to ensure that pressure is applied evenly. The contact

surfaces are generally fitted dry.

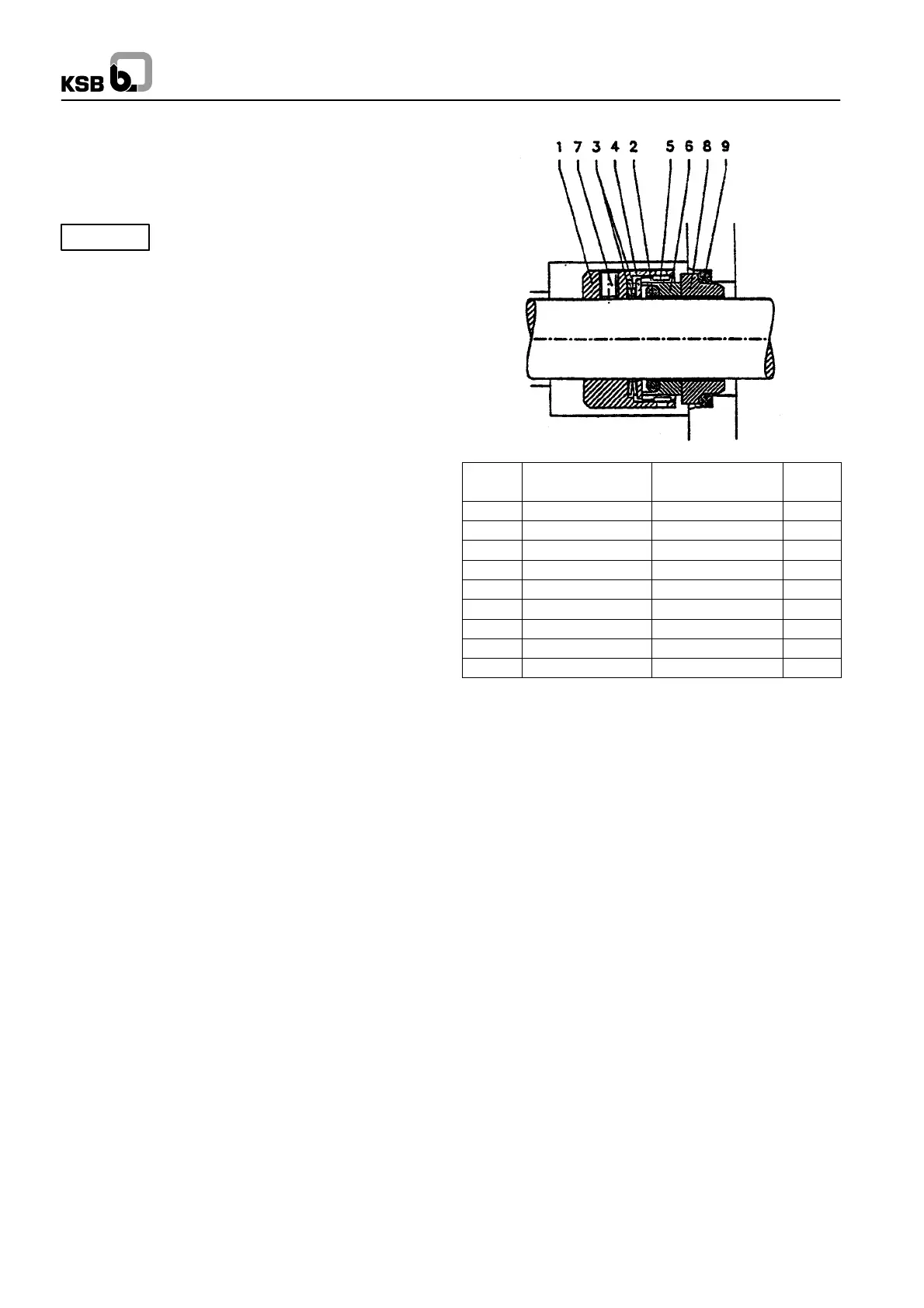

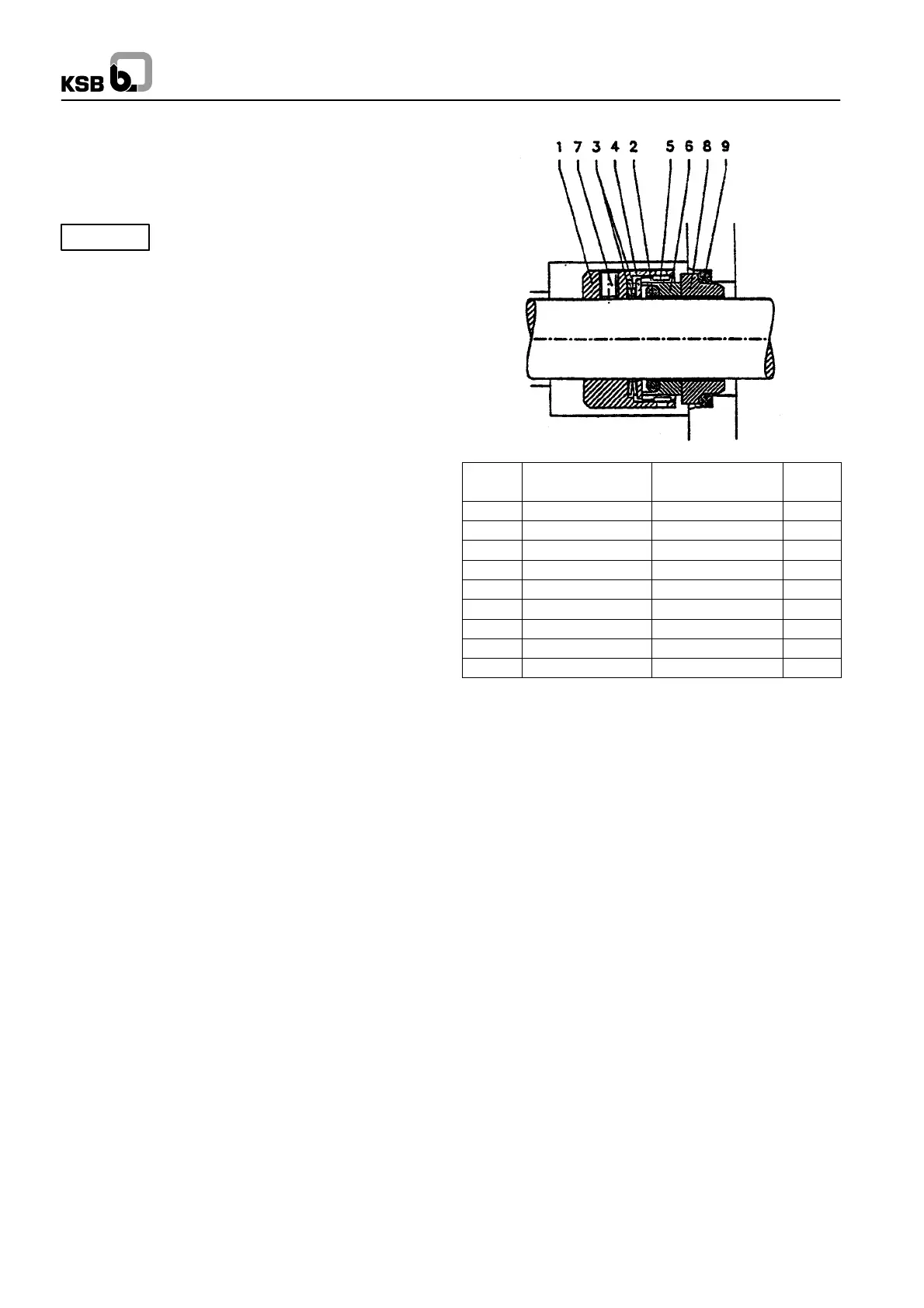

In mechanical seals of the M7N4 design, the rotating assembly

is supplied as one unit, consisting of a housing and pin ( 1 + 5),

fitted spring loaded ring (6), O --ring (2), spring (3), thrust plate

(4) and grub screws (7). The grub screws (7) must be loosened

so far as to prevent them from protruding from the housing (1)

at the inner diameter. The O--ring (2) can be slightly lubricated

to facilitate assembly.

The complete rotating assembly is pushed onto the shaft pro -

tection sleeve in compliance with the installation dimensions

which are given in the mech. seal drawing, or until it reaches the

stop on the shaft protection sleeve. Finally the grub screws are

tightened and secured with LOCTITE.

Item Description Material No. of

items

1 Housing Cr-Ni-Mo-steel 1

2 O--ring Viton 1

3 Spring Cr-Ni-Mo-steel 1

4 Thrust plate Cr-Ni-Mo-steel 1

5 Pin Cr-Ni-Mo-steel 2

6 Spring--loaded ring Si-SiC 1

7 Grub screw Cr-Ni-Mo-steel 2

8 Seat ring Si-SiC 1

9 O--ring Viton 1

Special instructions for mechanical seal assembly

· The contact faces must only be cleaned with propyl alcohol

and paper tissue.

-- Never use cleaning rags or cloth.

-- Clean carefully to remove any smears.

· Do not touch the contact faces with bare fingers.

· Never use force during mechanical seal assembly.

· Never put the spring--loaded ring and the seat ring face

down on the contact faces without the protective wrapping.

· Cover the contact face with a cardboard washer and press

the seat ring into its position slowly and evenly, lubricating

it with a generous amount of water or alcohol. Use a spacer

sleeve, if necessary. Verify that the seat ring position is nor-

mal to the shaft axis.

· In the mechanical s eal area, the s haft shall be slightly lubri-

cated with water, alcohol or silicone grease. Sealing ele-

ments made of EP rubber must never come into contact

with mineral oil base lubricants (swelling, possibly de-

composition).

Loading...

Loading...