Caution

Caution

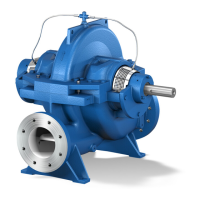

Omega

47

Coupling (N--EUPEX)

(Flexible couplings N--EUPEX and N--EUPEX--DS,

types A a nd ADS)

· N-- EUPEX couplings provide radial, angular, axial and tor -

sional flexibility. They are positive--locking.

· Torque is transmitted by flexible coupling elements (flexi-

bles).

· The non--linear spring characteristic and the favourable

damping properties of the N--EUPEX coupling effectively

counteract any dangerous increase in vibrations.

General instructions and safety notes

When fitting and removing N--EUPEX couplings please note

the following requirements:

D The coupling shall only be operated,

serviced or repaired by authorized,

skilled and duly qualified staff.

D The coupling shall only be used and

operated within the c onditions

stipulated in the technical specification

and supply contract.

D Unauthorized modification and removal

of protective equipment is not permitted.

D Any work on the coupling shall only be

performed with the machine shut down.

The driver must be secured against

inadvertent start-- up (e.g. by locking the

key--operated switch or removing the

power supply fuses). At the switch--on

point a notice shall be affixed to the

effect that work is being performed on

the coupling.

D Immediately switch off the driver when

changes in coupling behaviour occur,

such as changed running noises.

D The coupling must be suitably protected

against accidental contact.

Installation

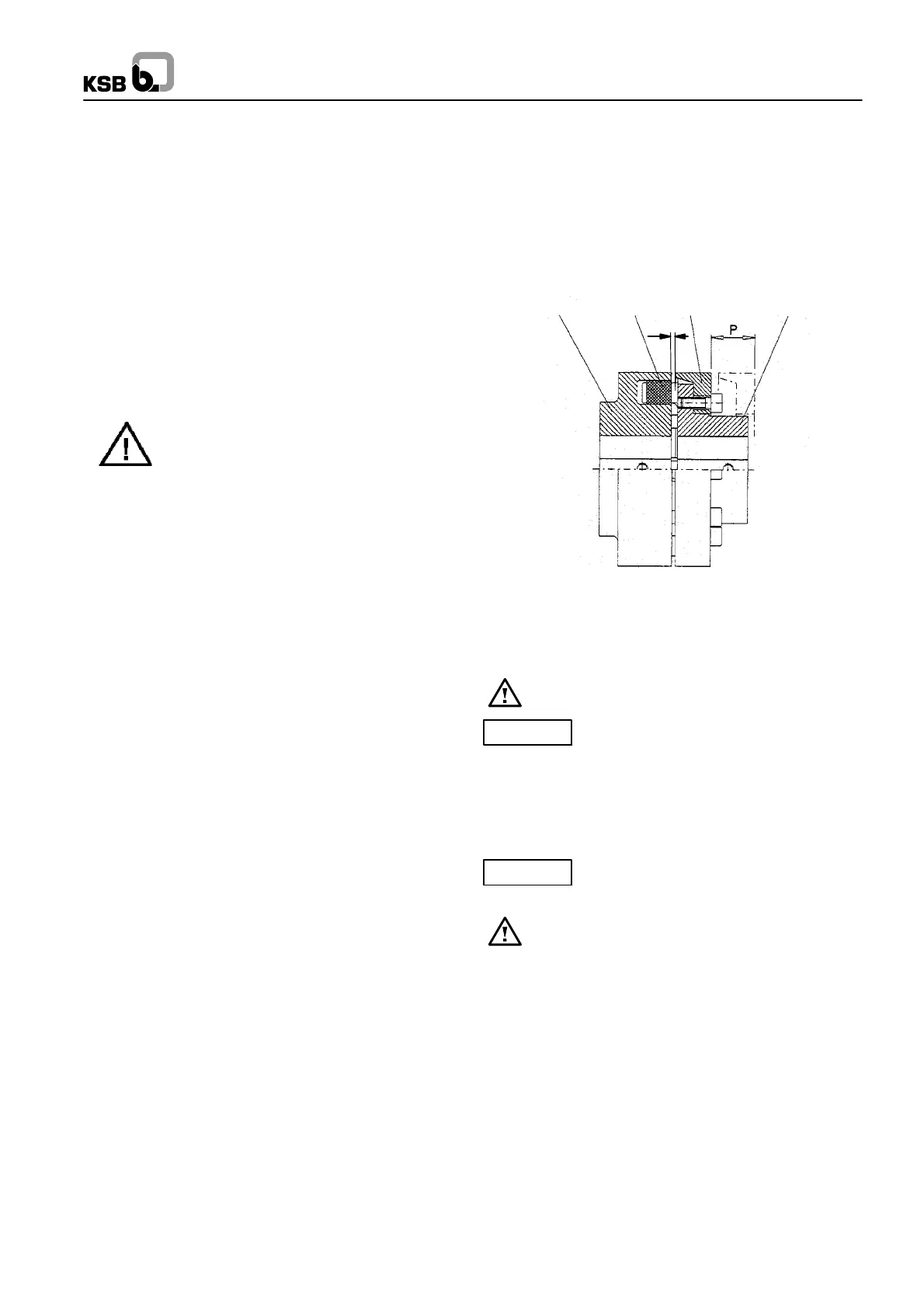

-- Design of types A / ADS

The N--EUPEX coupling types A / ADS consist of a coupling

part 1 which houses the flexible coupling blocks (12), the finger

part 3 and the coupling part 2, which bolts onto part 3.

The bolted connection between part 2 and part 3 makes it possi-

ble to separate the coupled machines without axial displace -

ment (if clearance P is observed).

S

1

Part 1

Part 2

Part 13

Part 12

-- Mounting the coupling components

Before fitting the coupling components, carefully clean the shaft

ends and the coupling parts. Make sure to remove the flexible

coupling blocks before cleaning the coupling parts with a sol-

vent.

Heed the manufacturer’s instructions for the use of

solvents.

Use appropriate tools when pulling on the

coupling parts, to prevent damage to the

shaft bearings due to the axial joining force.

Make sure to use suitable lifting tackle.

The shaft ends must not protrude from the hub faces. The cou-

pling is locked in axial direction by means of the set screw or

end plate, as applicable / set screw and end plate, respectively.

The set screws shall only be tightened by

means of a hexagon socket head wrench to

DIN 911, without extension.

Non--compliance with these instructions maycause

the coupling to burst. Danger of life by flying frag-

ments!

Loading...

Loading...