Caution

Omega

48

Heating up the coupling parts (to max. +150 °C) may facilitate

pulling on the coupling parts. If temperatures exceed +80 °C,

the flexible coupling blocks must be removed from the coupling

parts before the heating process.

Protect against burns from contact with hot compo-

nents!

If the coupling blocks have been removed, they shall be re--in-

stalled after the coupling parts have been pulled on. Make sure

the heated coupling parts have cooled down to under 80 _Cbe-

fore doing so. All coupling blocks used must be of identical size

and marking.

Push the machines to be coupled together.

Take appropriate precautions to prevent injury by

crushing.

Make sure to observe dimension S

1

. On types A and ADS, the

connection between parts 2 and 3 shall be re--established be -

fore aligning the coupling, and the tightening torque of the scre -

wed connection between parts 2 and 3 shall be c hecked (for

tightening torques and clearance S

1

please refer to point 6.6).

Aligning the coupling

(Also refer to section 5.3.2).

The c ouplings will only tolerate misalignment of the shaft ends

to be coupled to a certain extent.

When aligning the coupling, the radial and angular misalign-

ment of the shaft ends should therefore be minimized. With

identical operating conditions, the useful life of the flexible cou-

pling blocks will be increased as a result.

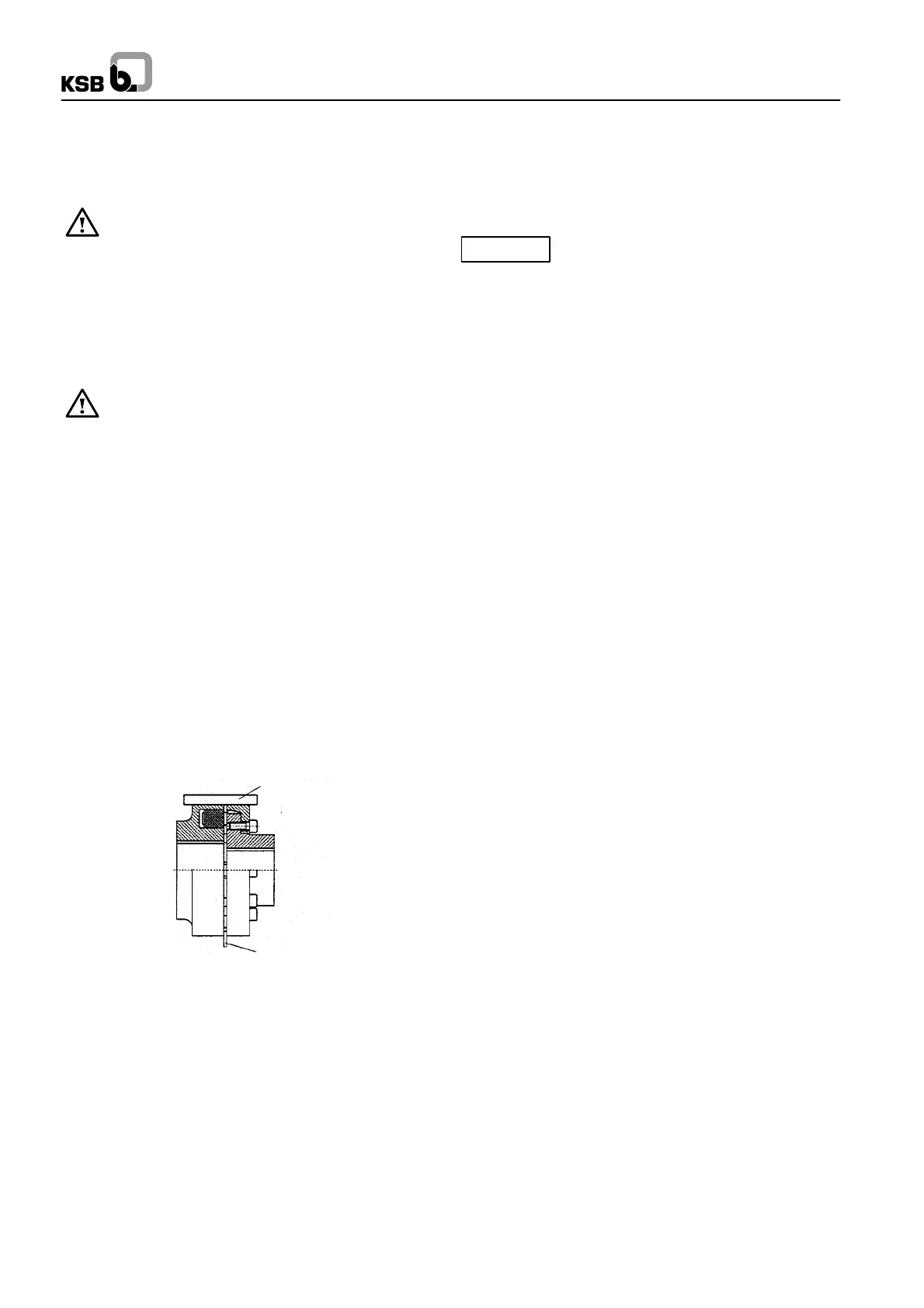

Coupling alignment shall be effected in two planes which are

normal to each other. Use a straight-- edge (radial misalign-

ment) and feeler gauge (angular misalignment) as shown be-

low to verify.

Feeler gauge

Straight edge

Using a dial micrometer will make for increased measuring ac-

curacy.

To allow one shaft end to rotate freely, the driving s ection can

be separated on types A and ADS b y loosening the screwed

connection between parts 2 and 3 and pulling part 3 out of the

recesses in part 1.

After the connection has been

re--established, check the tightening

torque of the bolts.

Loading...

Loading...