k

d

2

number of

holes n

Mating flange

All flanges designed as plate flanges

Omega

73

Standard flange connections

1)

:

Pump

Size

JL 1040 / GGG-NiCrNb 202

Nominal pressure acc. to:

JS 1030 / 1.4517

Nominal pressure acc. to:

DIN 2501

ISO 7005/2

BS 4504 ANSI B 16.1 DIN 2501

ISO 7005/2

BS 4504 ANSI B 16.1

300-560

PN 16 Table 16/11

300-700

PN 25 Table 25/11

Class 250

350-430

PN 25 Table 25

11 Class 250

350-510

a

e

ass

5

1)

Other flange connections on request

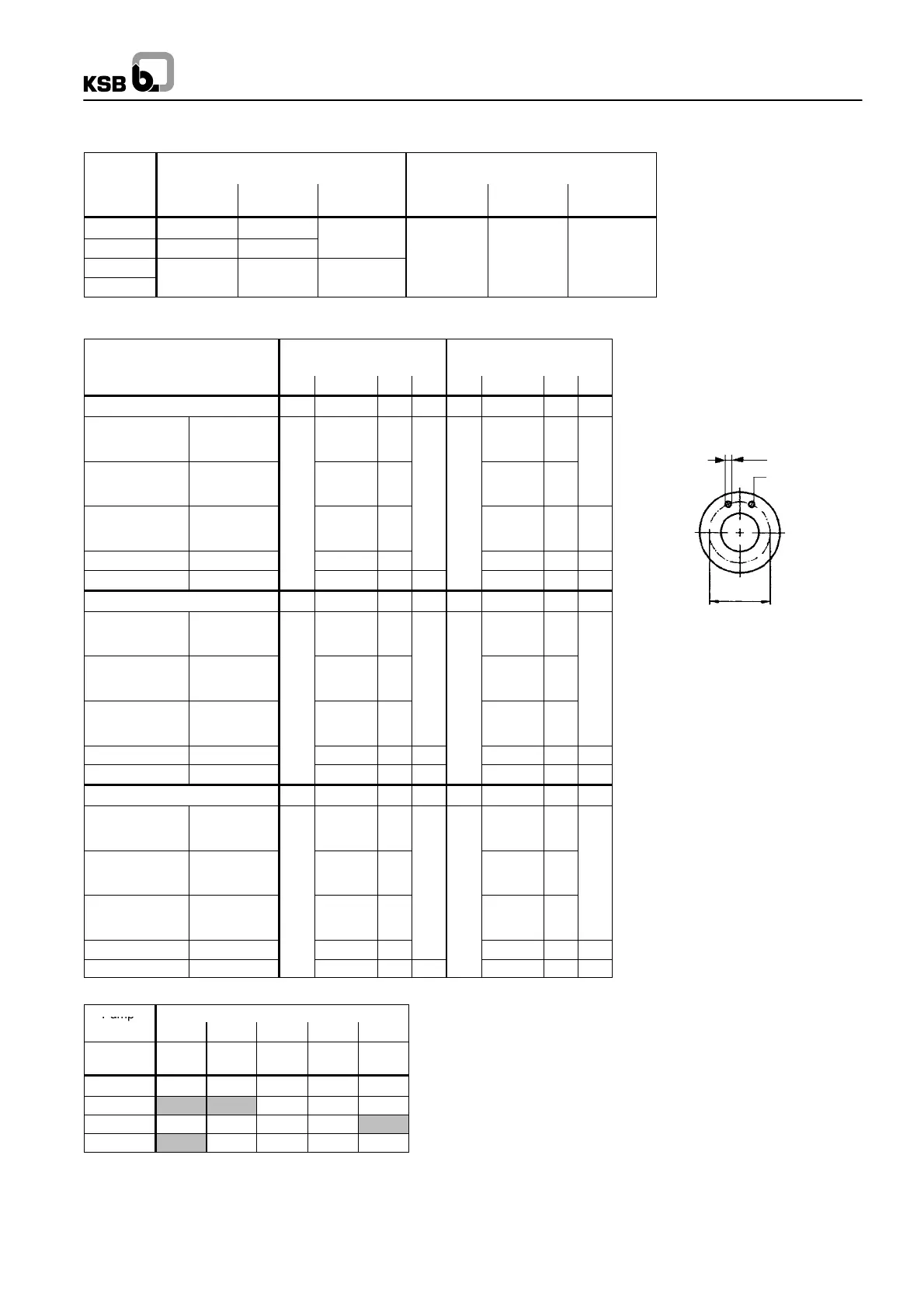

Flange dimensions -- Hole pattern All dimensions in mm

Standard

Suction flange Discharge flange

DN d

2

k n DN d

2

k n

Pump sizes 300-560 and 300-700 400 300

ISO 7005/2

DIN 2501

BS 4504

PN 10

Table 10/11

28 (M24) 515 23 (M20) 400

ISO 7005/2

DIN 2501

BS 4504

PN 16

Table 16/11

31 (M27) 525

16

28 (M24) 410

ISO 7005/2

DIN 2501

BS 4504

PN 25

Table 25/11

37 (M33) 550 31 (M27) 430 16

ANSI B 16.1 Class 125 28 (M24) 540 28 (M24) 432

12

ANSI B 16.1 Class 250 34 572

20

31 (M27 451

16

Pump size 350-430 450 350

ISO 7005/2

DIN 2501

BS 4504

PN 10

Table 10/11

28 (M24) 565 23 (M20) 460

ISO 7005/2

DIN 2501

BS 4504

PN 16

Table 16/11

31 (M27) 585

20

28 (M24) 470

16

ISO 7005/2

DIN 2501

BS 4504

PN 25

Table 25/11

37 (M33) 600 34 (M30) 490

ANSI B 16.1 Class 125 31 (M27) 578

16

28 (M24) 476

12

ANSI B 16.1 Class 250 34 629

24

31 (M27) 514

20

Pump size 350-510 400 350

ISO 7005/2

DIN 2501

BS 4504

PN 10

Table 10/11

28 (M24) 515 23 (M20) 460

ISO 7005/2

DIN 2501

BS 4504

PN 16

Table 16/11

31 (M27) 525

16

28 (M24) 470

16

ISO 7005/2

DIN 2501

BS 4504

PN 25

Table 25/11

37 (M33) 550 34 (M30) 490

ANSI B 16.1 Class 125 28 (M24) 540 28 (M24) 476

12

ANSI B 16.1 Class 250 34 572

20

31 (M27) 514

20

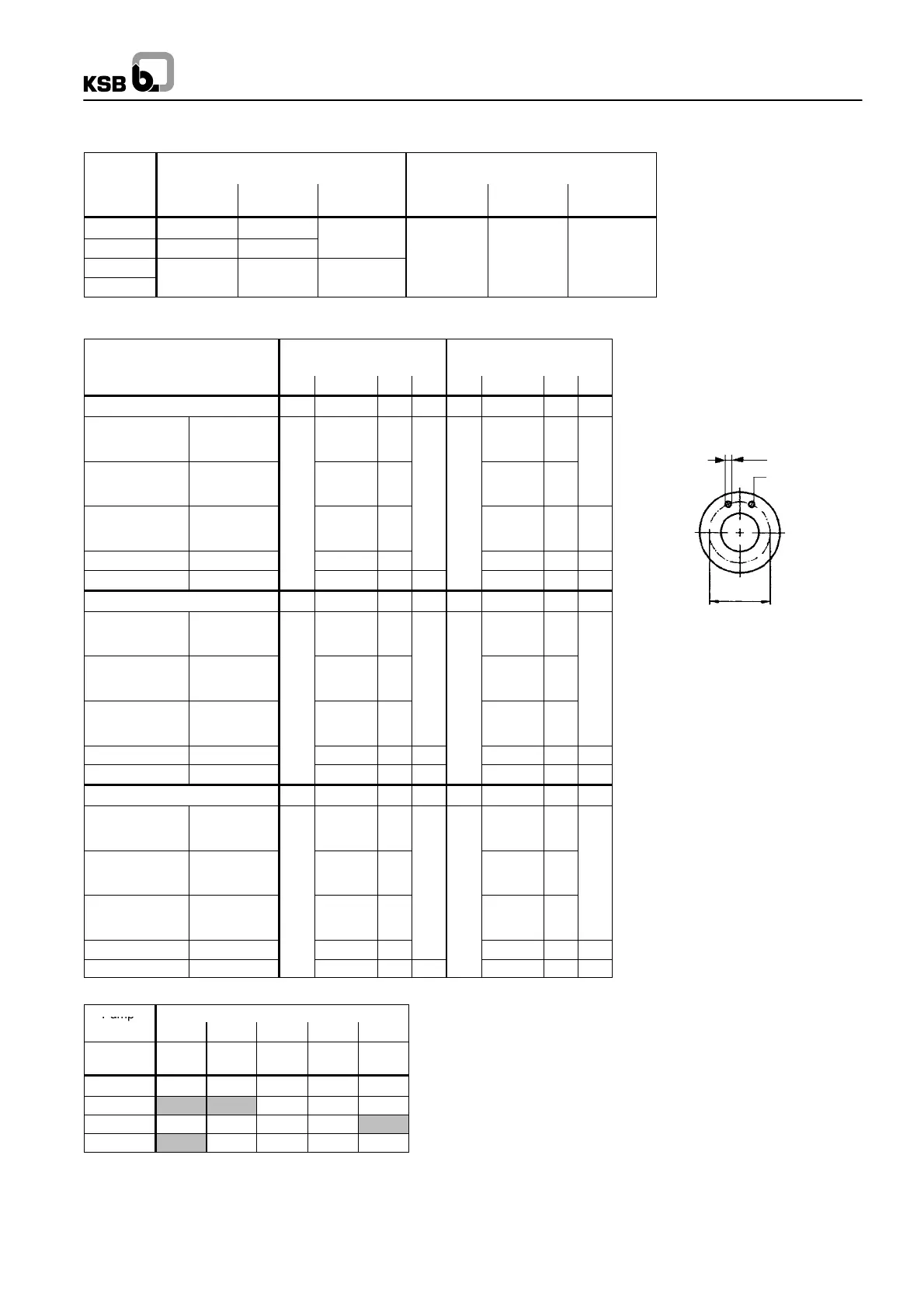

Baseplate / motor combinations

Pump

Motor Size

Size

315M 315L 315 355 400

No of po-

les

4 4 4 4 4

300-560 13 13 13 17 17

300-700 13 18 17

350-430 13 13 13 18

350-510 13 13 18 17

N.B.: - The numbers listed in the table indicate the relevant baseplate numbers.

- The baseplate numbers shown in the boxes also serve to select the correct motor size for the listed pump size.

- Units comprising a motor size 315 and larger are completely assembled for verification and adjustment of the individual

components. Before shipment, the units are dismantled again and the components packed / shipped separately.

Loading...

Loading...