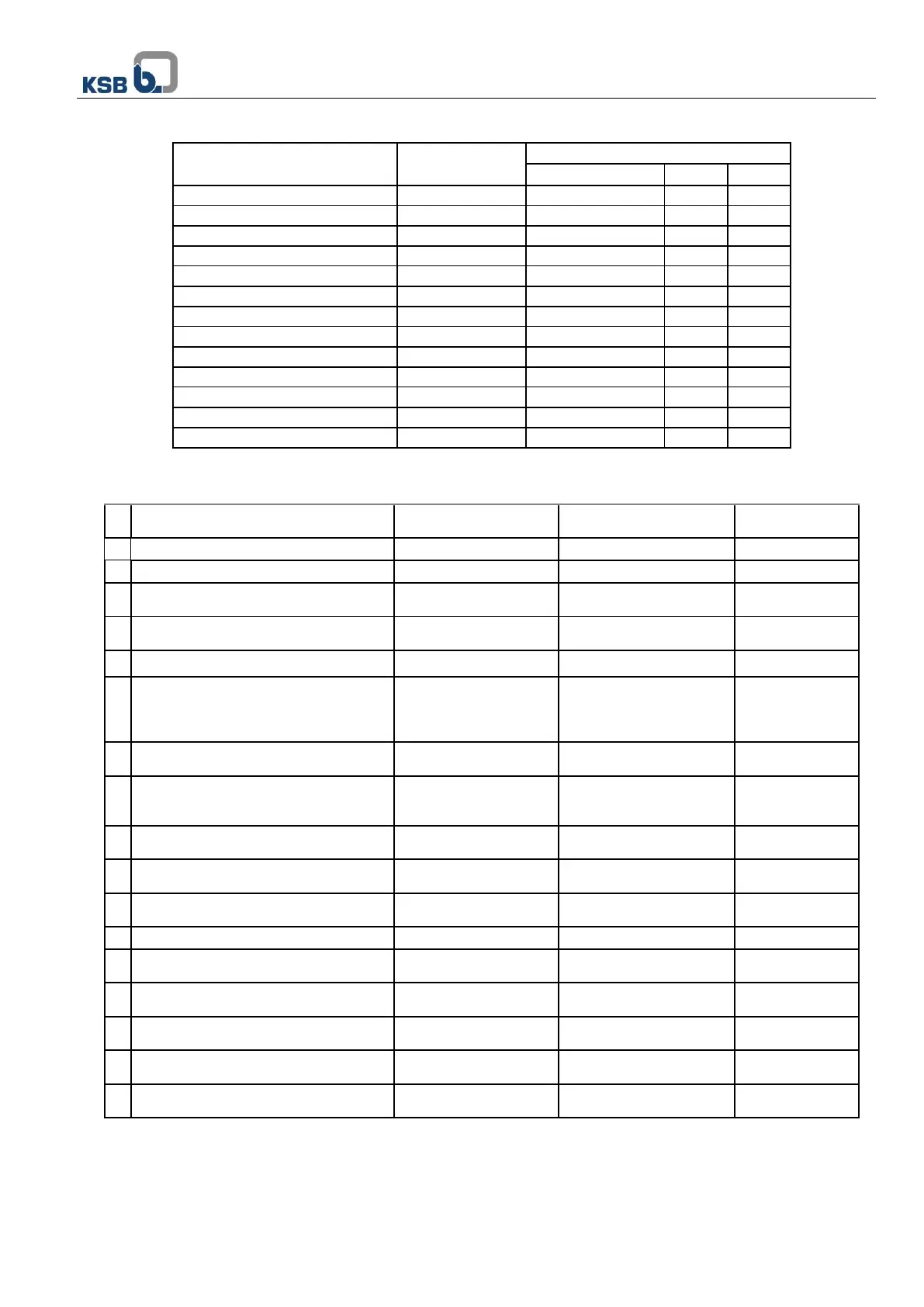

7.6 Recommended spare parts

Recommended spare parts (1)

Flexible coupling part (set)

(1) Amounts recommended for a continuous service pump

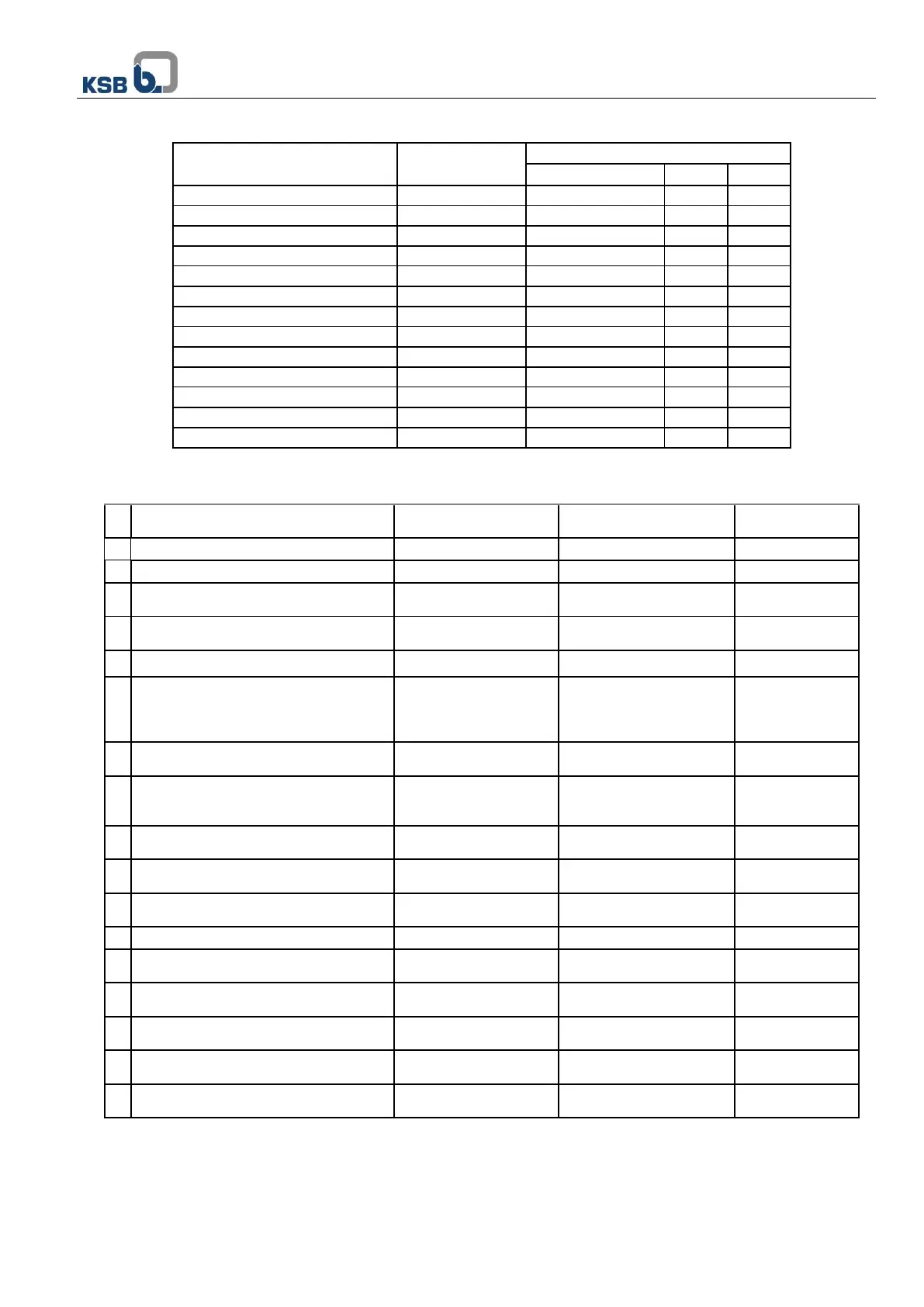

7.7 Preventative maintenance

DESCRIPTION OF THE OPERATION

TO BE CARRIED OUT

Check for mechanical seal leaks

Check for leaks between the casing and

the cover

Check for leaks between flanges or

connections

Check for heating of the bearings

Check tightness of connecting bolts for

motor/base frame, pump/base frame,

cover/casing, support/support

supplement, flanges/casing

Check and align the coupling

See point 5.2 of the

manual

Twice a year and every

time it is dismounted

Check and dismount the

pump. See point 7 of the

manual

1, 2, 3, 4, 5, 6, 9,

10, 14

Check for wear of the gears

Dismount the casing.

Visual inspection

Check for wear of the shaft and bearings

Dismount cover, Visual

inspection

Change the rubber coupling plugs

See point 7.4.3 of the

manual

Check the relief valve spring

Check functional characteristics loss

Check the

installation, 8

When the leaks are

excessive

Change the mechanical seal

See point 7.4.4 of the

manual

See point 7.4.5 of the

manual

Every time they are

removed

When the leaks are

excessive

Loading...

Loading...