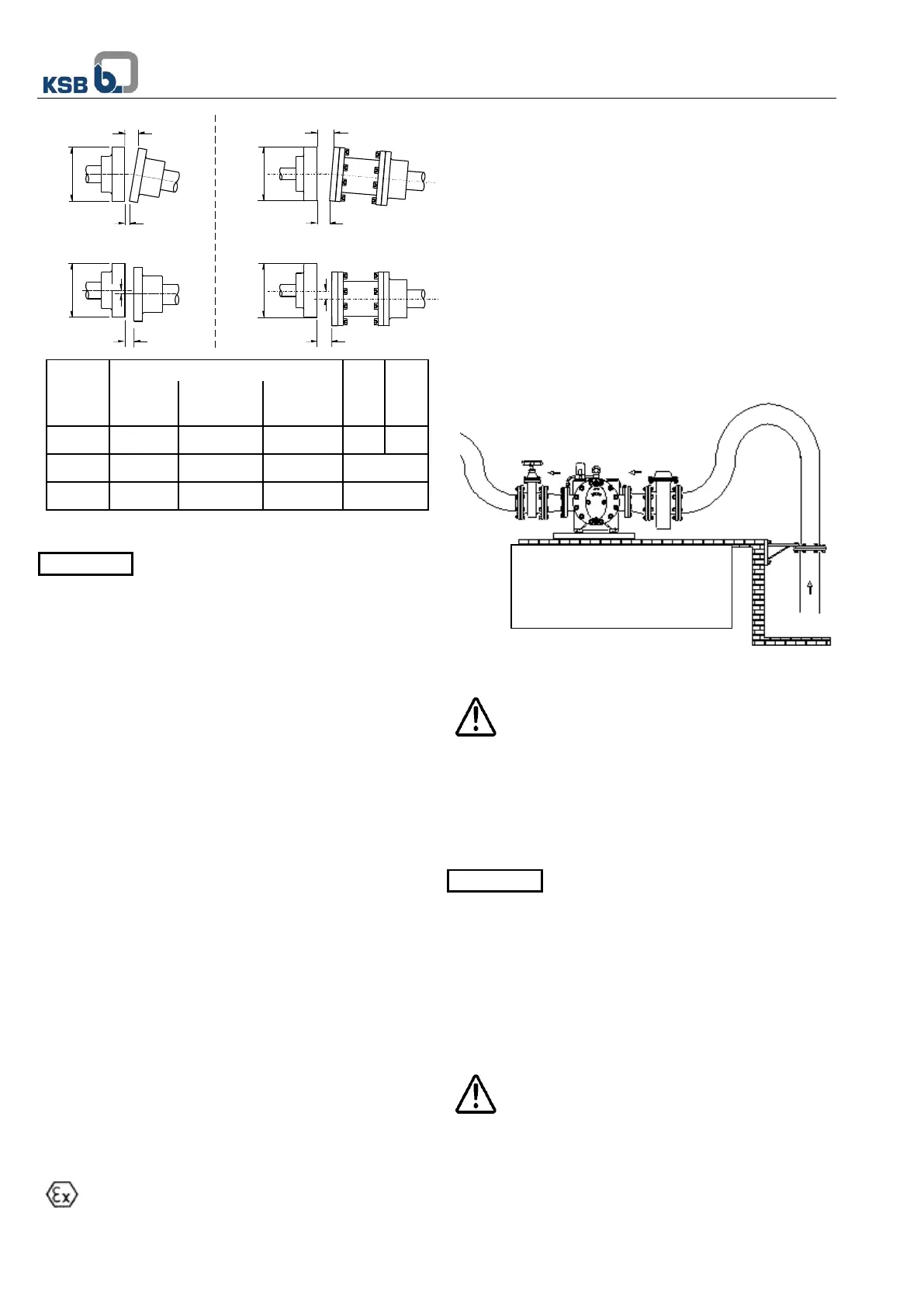

Note: For other types of coupling, see their instructions

manual.

The equipment must always be aligned after

mounting and preparing for start up, check

that the assembly can rotate freely when operated by hand

5.2.2 Close coupled groups

Levelling

Use a spirit level to level the equipment. Use wedges to alter

the height at different points. The maximum deviation

permitted is 0.2 mm/m.

Pump - motor alignment

The equipment is aligned at factory, and this alignment must

never be lost. The following instructions must be followed

when dismounting or returning the motor:

- Check that the flange support surface of the motor

support and of the motor itself are perfectly clean and

smooth.

- The motor shaft should easily enter the pump shaft (or

bushing). If it does not, do not force assembly as this will

damage the motor bearings. Check the alignment

between both shafts and repair or replace them as

necessary.

5.2.3 Vertical groups

Levelling

Use a spirit level to level the equipment. Use wedges to alter

the height at different points. The maximum deviation

permitted is 0.2 mm/m.

The separation between the two coupling halves must be

maintained.

Pump - motor alignment

In order to prevent misalignment between the shafts, it is

necessary to correctly install, check and maintain the coupling.

See the instructions manual for the coupling.

The coupling may produce a source of ignition or high

temperature in the event of incorrect operation. The

coupling must be classified as non-electric equipment with at

least the same type of area and temperature as the pump. It is

necessary to follow the instructions in the coupling manual

which is included with the pump.

The equipment is aligned at factory, and this alignment must

never be lost. The following instructions must be followed

when dismounting or returning the motor:

- Check that the flange support surface of the motor

support and of the motor itself are perfectly clean and

smooth.

- Check the correct separation between the two halves of

the coupling.

- Check that the alignment between both shafts is correct

by turning the equipment by hand.

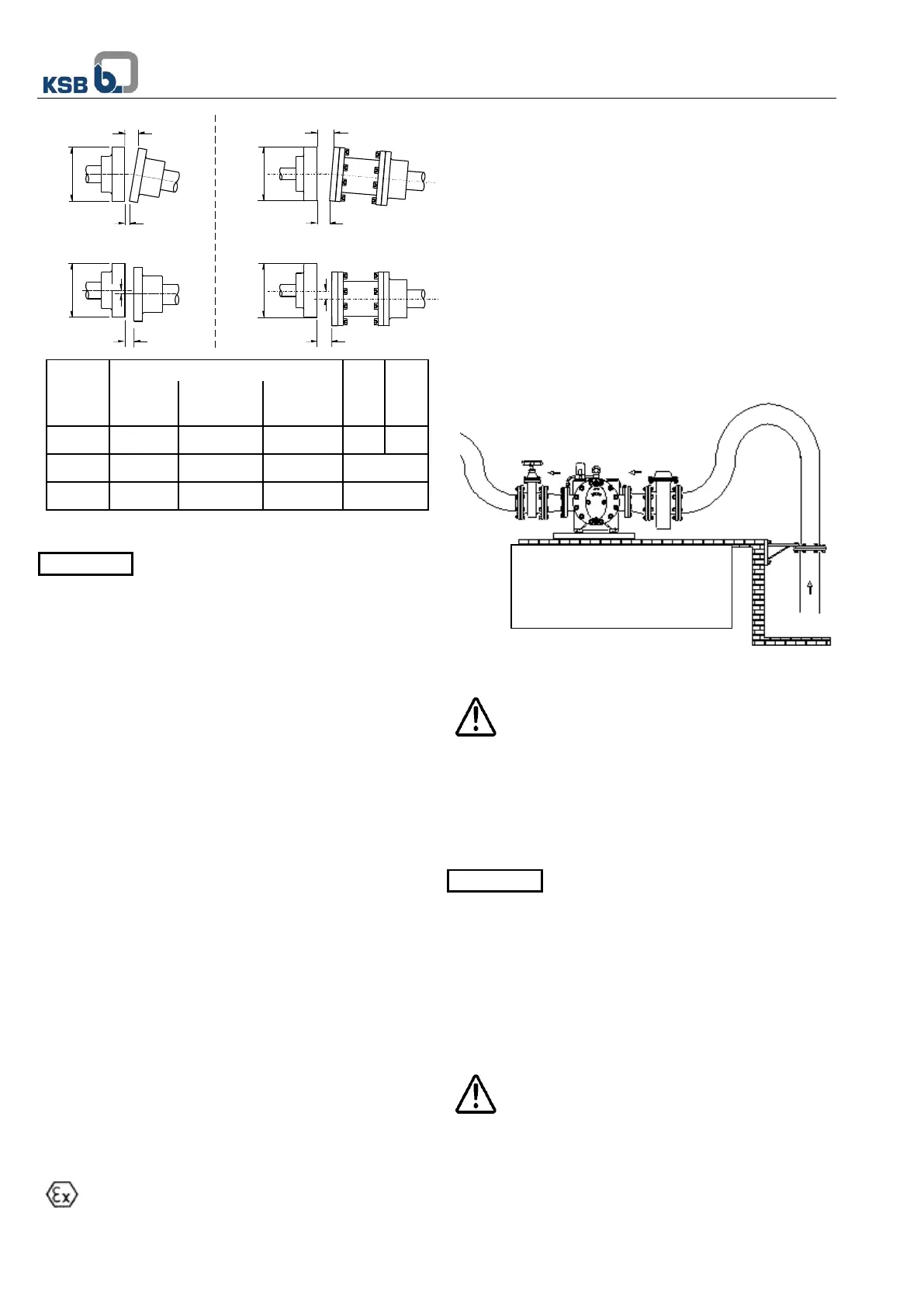

5.3 Pipe joint

In no case can the pump be used as a fixed point for the

pipes.

The pipe system must at no time exercise force in

excess of the values shown in the chart in point 4.4

(due to connection, thermal variation, etc) in the

pump.

The short pipes must be of at least the diameter of the pump

connections. The diameter of long pipes is, in some cases,

determined by economic criteria.

Transition pieces at larger diameters must have an extension

angle of around 8°, in order to prevent pressure drops.

The convenience of installing foot valves

when the pump is working in suction or

retention when loaded, along with seal valves, will depend on

the type of installation.

The thermal expansions of the pipes must be compensated

with suitable measures, in order not to exceed the maximum

strains permitted on the pump.

The diameters of the pipes, valves and accessories must be

calculated in line with the load losses envisaged in the

installation, meaning the fluid speeds will be suitable for the

circuit and the viscosity of the fluid.

Exceeding the admitted strains of the pipes may lead

to leaks in the pump and to the fluid escaping.

Hazard of death with hot liquids!

When designing the suction piping check that the available

NPSH is higher than required NPSH of the pump in order to

avoid cavitation in whole admissible operation range.

The suction and impulsion nozzle covers of the pump must be

removed before connecting the pipes.

Loading...

Loading...