The fluid enters the pump axially via the suction nozzle (6) and is accelerated

outward by the rotating impeller (7). In the flow passage of the pump casing the

kinetic energy of the fluid is converted into pressure energy. The fluid is pumped to

the discharge nozzle (2), where it leaves the pump. The clearance gap (1) prevents

any fluid from flowing back from the pump casing into the suction nozzle. At the

rear side of the impeller, the shaft (4) enters the hydraulic system via the casing cover

(3). The shaft passage through the cover is sealed to atmosphere with a shaft seal (8).

The shaft runs in rolling element bearings (9 and 10), which are supported by a

bearing bracket (5) connected to the casing cover.

The pump is sealed by a standardised mechanical seal.

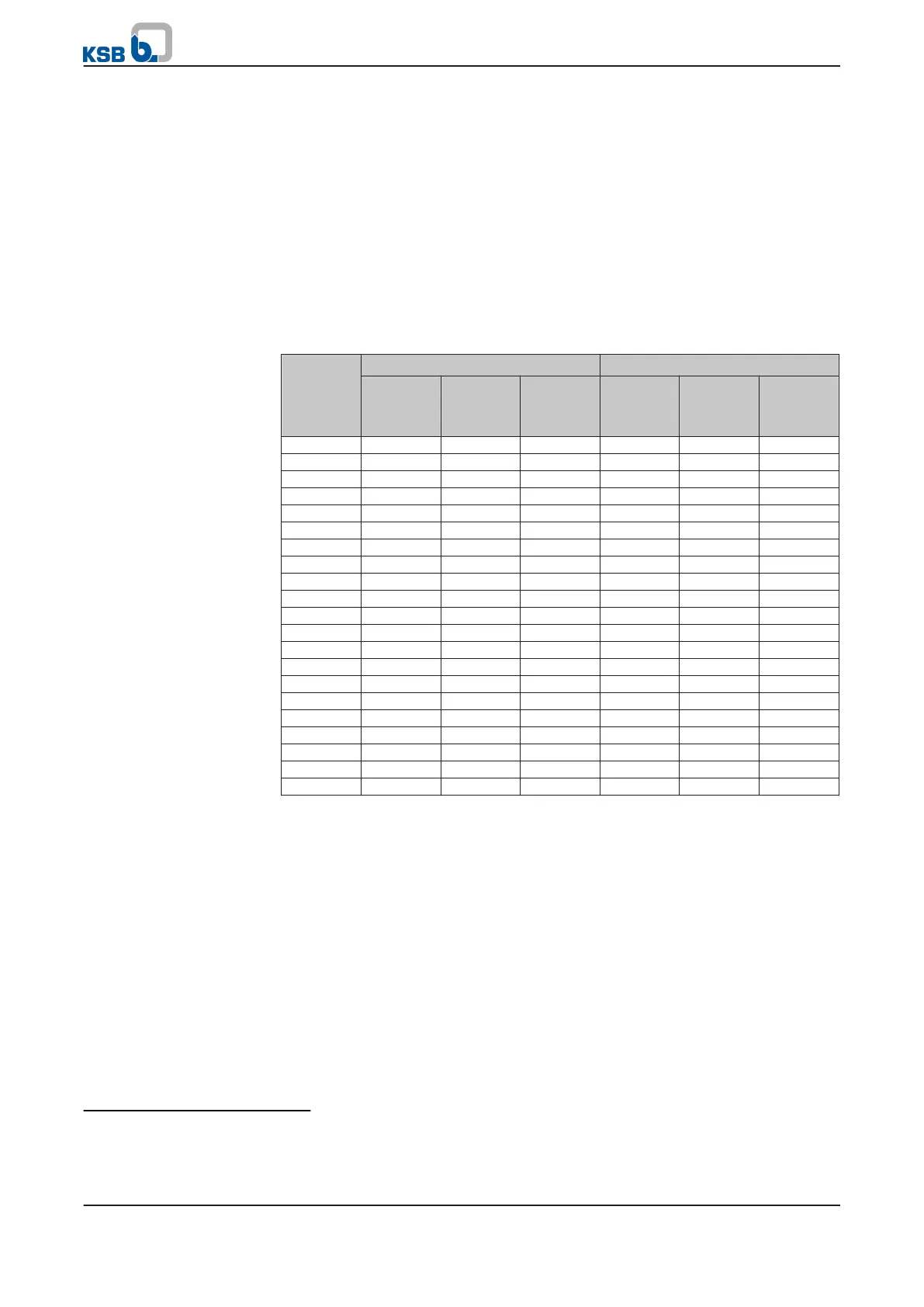

4.6 Noise characteristics

Table 10: Surface sound pressure level L

pA

3)4)

Rated

power

input

P

N

[kW]

Pump Pump set

960 rpm

760 rpm

[dB]

1450 rpm

[dB]

2900 rpm

[dB]

960 rpm

760 rpm

[dB]

1450 rpm

[dB]

2900 rpm

[dB]

1,5 52 53 54 56 58 63

2,2 53 55 56 58 60 66

3 55 56 57 60 62 68

4 56 58 59 61 63 69

5,5 58 59 61 62 65 71

7,5 59 61 62 64 66 72

11 61 63 64 65 68 74

15 63 65 66 67 69 75

18,5 64 66 67 68 70 76

22 65 67 68 68 71 77

30 66 68 70 70 72 78

37 67 70 71 70 73 79

45 68 71 72 71 74 80

55 69 72 73 72 74 80

75 71 73 75 73 76 81

90 71 74 76 73 76 82

110 72 75 77 74 77 82

132 73 76 78 75 77 83

160 74 77 79 75 78 84

200 75 78 80 76 79 84

250 - 79 81 - 80 85

4.7 Scope of supply

Depending on the model, the following items are included in the scope of supply:

▪ Pump

▪ Torsion-resistant flexible disc coupling

▪ Coupling guard

▪ Welded baseplate for the complete unit (pump and motor), in torsion-resistant

design

▪ As required

4.8 Dimensions and weights

For dimensions and weights please refer to the general arrangement drawing/outline

drawing of the pump/pump set.

Function

Sealing

Coupling

Contact guard

Baseplate

Special accessories

3)

Spatial average; as per ISO 3744 and EN 12639; valid for pump operation in the Q/Qopt = 0.8 - 1.1 range and for non-

cavitating operation. If noise levels are to be guaranteed: Add +3 dB for measuring and constructional tolerance.

4)

Increase for 60 Hz operation: 3500 rpm +3 dB, 1750 rpm +1 dB, 1160 rpm ±0 dB

4 Description of the Pump (Set)

RPH

19 of 76

Loading...

Loading...