1. If required, suspend or support the back pull-out unit to prevent it from tipping

over. Then slide it into volute casing 102 with a new gasket 411.10.

2. Tighten nut 920.01 at volute casing 102. Observe the tightening torques.

(⇨ Section 7.6.1 Page 53)

7.5.6

Mounting the motor

NOTE

Steps 1 and 2 do not apply to versions with spacer-type coupling.

1. Shift the motor to connect it to the pump via the coupling.

2. Fasten the motor to the baseplate.

3.

Align pump and motor.

4. Connect the motor to the power supply (refer to manufacturer's product

literature).

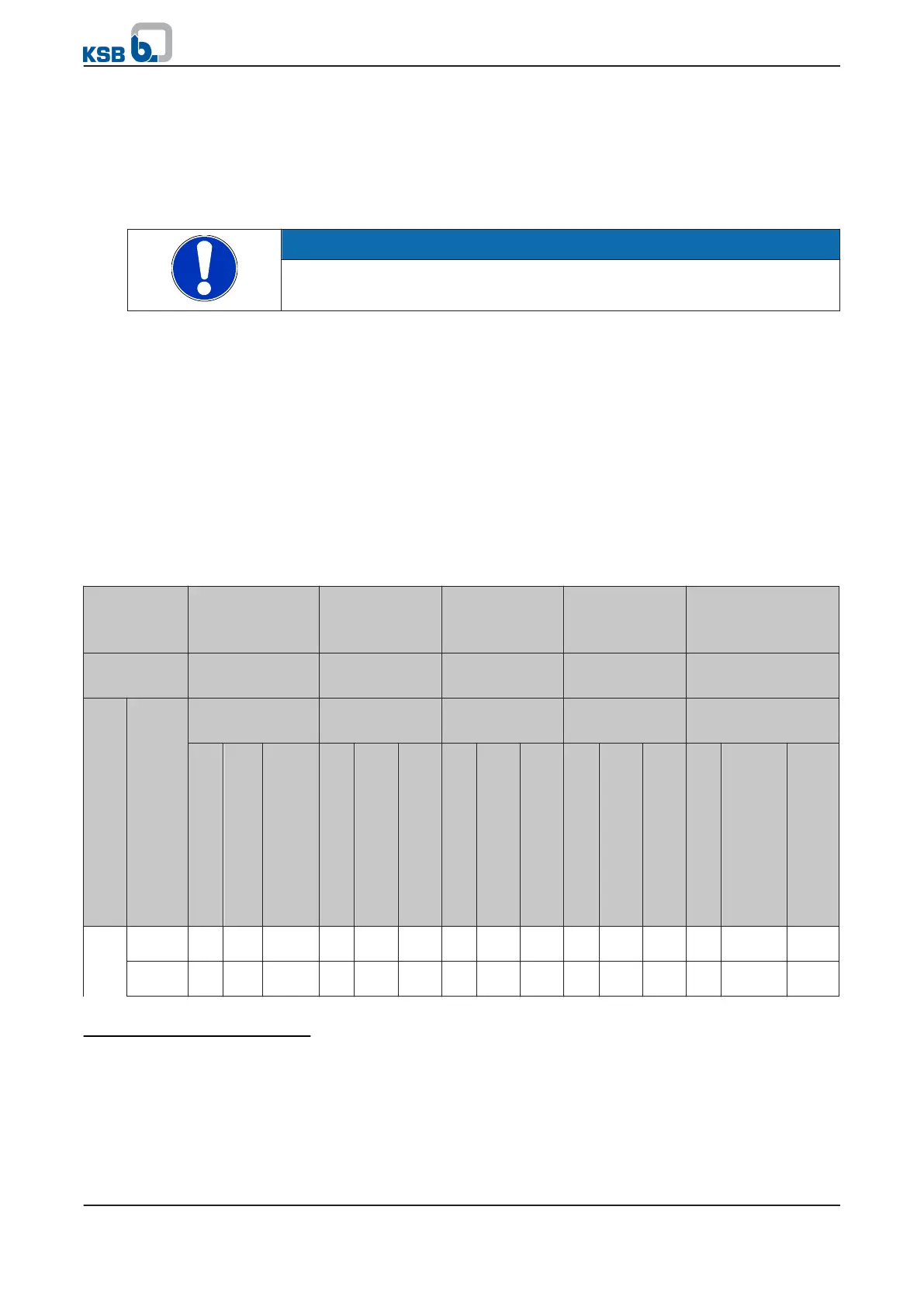

7.6 Tightening torques

7.6.1 Tightening torques of the pump

Use a torque wrench to tighten the screwed connections (902.01/920.01) between the

volute casing and the casing cover.

Table 20: Tightening torques of screwed connections

Material

(Asia and

Americas)

A 193 Grade B7/

B16 /

A 540 Grade B24

A 193 Grade

B7/B16

10.9 -- CF6M/Type 316

Material

(Europe)

1.7709/1.6772

(Monix 3K)

C35E+QT 8.8 A4-70 1.4571/1.4021

Bearing bracket

Size

Stud

14)

902.01

Stud

14)

902.15

Hexagon head

bolt 901.37

Stud

14)

902.02

Impeller nut 922.01

or impeller screw 906

Quantity

Thread

Tightening torque

15)16)

[Nm]

Quantity

Thread

Tightening torque

15)16)

[Nm]

Quantity

Thread

Tightening torque

15)

[Nm]

Quantity

Thread

Tightening torque

15)16)

[Nm]

Quantity

Thread

Tightening torque

15)17)

[Nm]

B02S 25-180 12 M 16

163

18)

/

280

19)

4 M 16 83 4 M 10 45 4 M 16 133 1 M 14x1.5

80

20)

25-230 16 M 16

163

18)

/

280

19)

4 M 16 83 4 M 10 45 4 M 16 133 1 M 14x1.5

80

20)

14)

Stud to DIN 938/DIN 939 with hexagon nuts to ISO 4032.

15)

These values are determined on the basis of a friction coefficient of μ = 0.1

2.

16)

After repeated tightening of the threads and in case of good lubrication the values shall be reduced by 15 to 20 %.

17)

Re-tighten impeller nut 922.01 or impeller screw 906 some 20 to 30 minutes after assembly. Bend back lock washer 931.02.

18)

Values for 1.7709 / A 193 Grade B7/B16 /

19)

Values for 1.6772 (Monix 3K) / A 540 Grade B24

20)

Values for 1.4571 / A 276 Type 316Ti

7 Servicing/Maintenance

RPH

53 of 76

Loading...

Loading...