CAUTION

Aggressive flushing and pickling agents

Damage to the pump!

▷ Match the cleaning operation mode and duration for flushing and pickling

service to the casing and seal materials used.

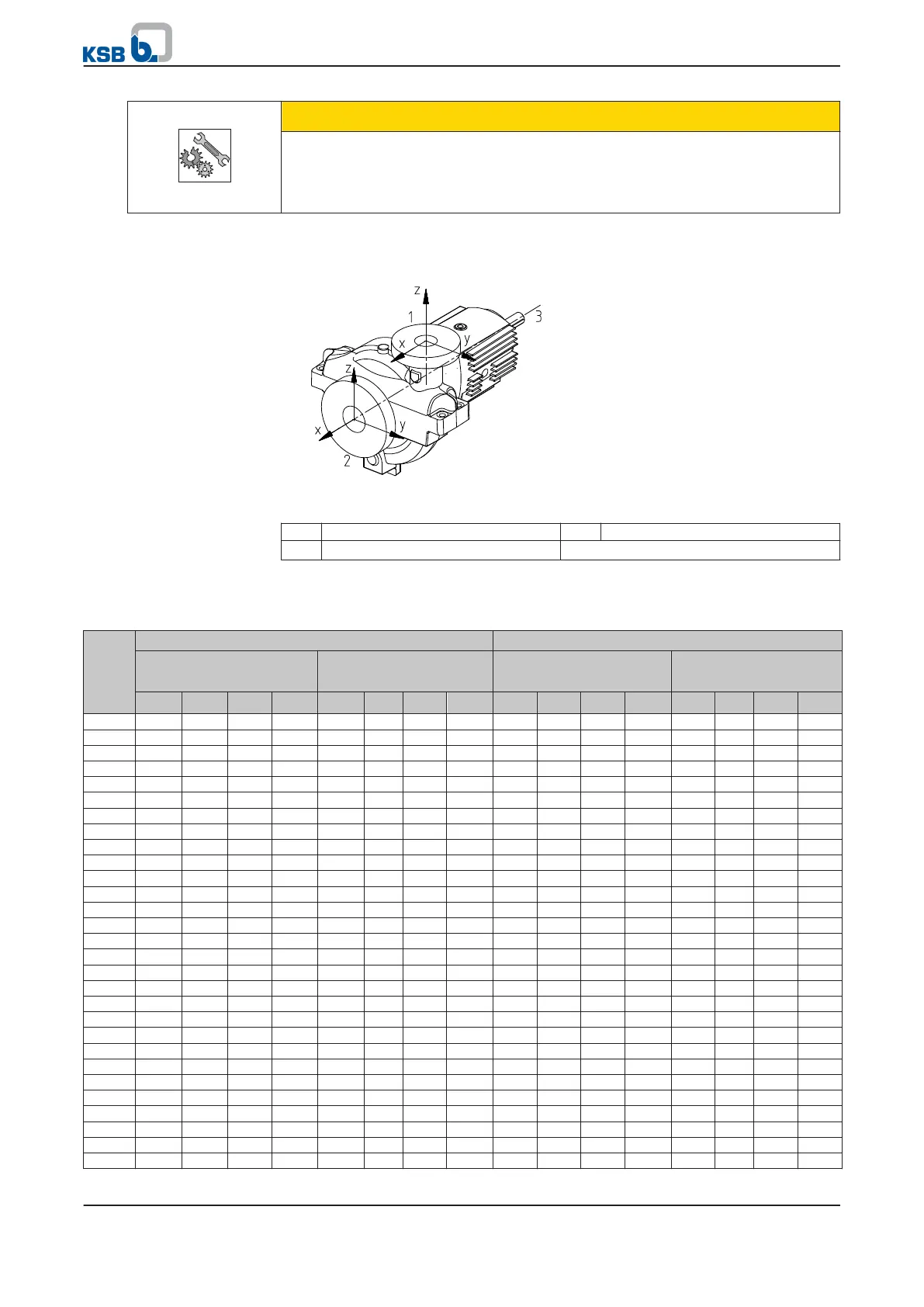

5.4.2 Permissible forces and moments at the pump nozzles

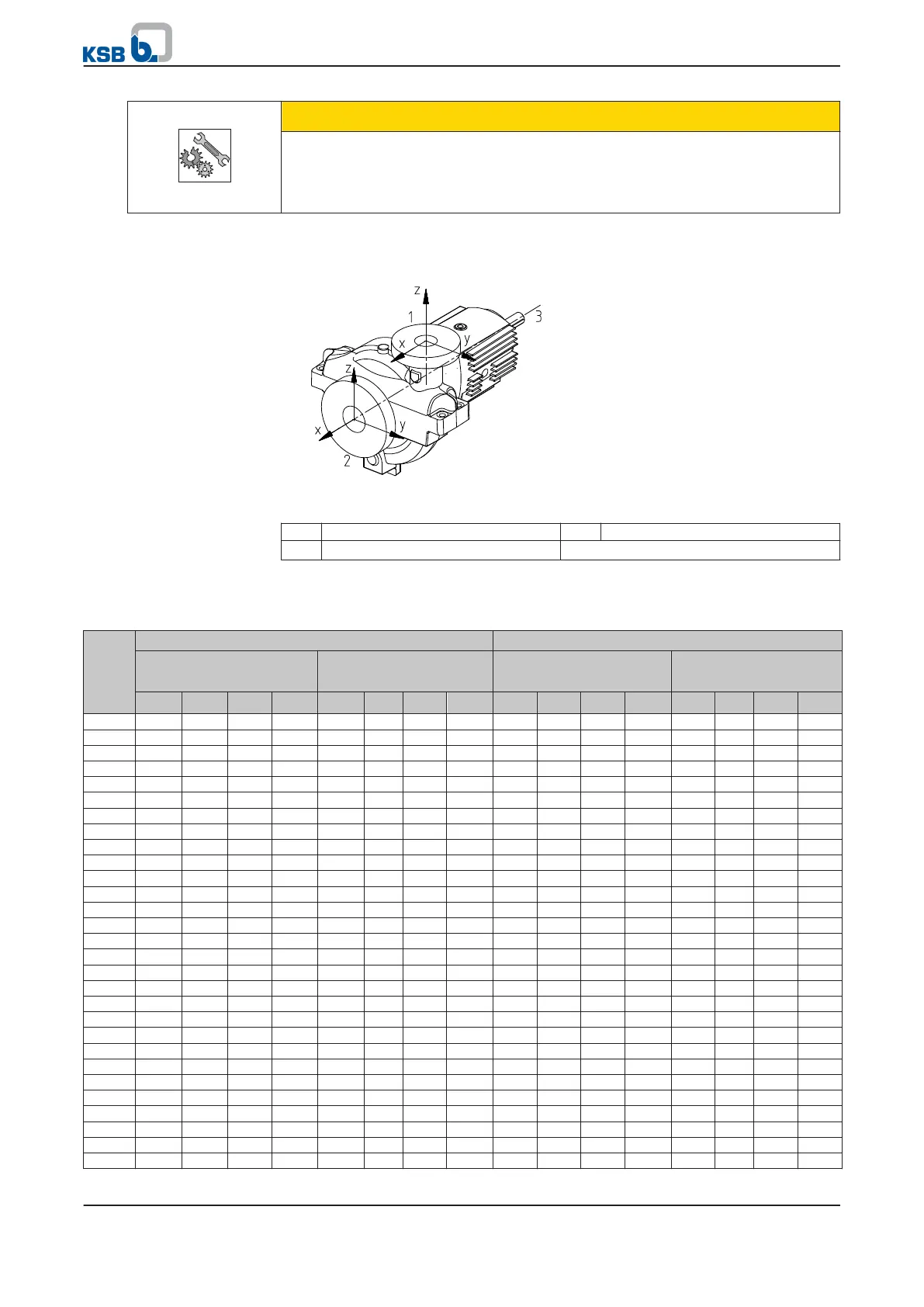

Fig. 8: Coordinate system of forces and moments

1 Discharge nozzle 2 Suction nozzle

3 Shaft centreline

The pumps are designed to withstand twice the piping forces and moments required

by API 610.

Table 11: Forces and moments at the pump nozzles

Size

Suction nozzle Discharge nozzle

Forces

[N]

Moments

[Nm]

Forces

[N]

Moments

[Nm]

F

x

F

y

F

z

F

res

M

x

M

y

M

z

M

res

F

x

F

y

F

z

F

res

M

x

M

y

M

z

M

res

25-180 1780 1420 1160 2560 920 460 700 1240 1420 1160 1780 2560 920 460 700 1240

25-230 1780 1420 1160 2560 920 460 700 1240 1420 1160 1780 2560 920 460 700 1240

40-180 1780 1420 1160 2560 920 460 700 1240 1420 1160 1780 2560 920 460 700 1240

40-230 1780 1420 1160 2560 920 460 700 1240 1420 1160 1780 2560 920 460 700 1240

40-280 1780 1420 1160 2560 920 460 700 1240 1420 1160 1780 2560 920 460 700 1240

40-181 1780 1420 1160 2560 920 460 700 1240 1420 1160 1780 2560 920 460 700 1240

40-231 1780 1420 1160 2560 920 460 700 1240 1420 1160 1780 2560 920 460 700 1240

40-281 1780 1420 1160 2560 920 460 700 1240 1420 1160 1780 2560 920 460 700 1240

40-361 1780 1420 1160 2560 920 460 700 1240 1420 1160 1780 2560 920 460 700 1240

50-180 2660 2140 1780 3860 1900 940 1440 2560 1420 1160 1780 2560 920 460 700 1240

50-230 2660 2140 1780 3860 1900 940 1440 2560 1420 1160 1780 2560 920 460 700 1240

50-280 2660 2140 1780 3860 1900 940 1440 2560 1420 1160 1780 2560 920 460 700 1240

50-360 2660 2140 1780 3860 1900 940 1440 2560 1420 1160 1780 2560 920 460 700 1240

50-450 2660 2140 1780 3860 1900 940 1440 2560 1420 1160 1780 2560 920 460 700 1240

80-180 3560 2840 2320 5120 2660 1360 2000 3600 2140 1780 2660 3860 1900 940 1440 2560

80-230 3560 2840 2320 5120 2660 1360 2000 3600 2140 1780 2660 3860 1900 940 1440 2560

80-280 3560 2840 2320 5120 2660 1360 2000 3600 2140 1780 2660 3860 1900 940 1440 2560

80-360 3560 2840 2320 5120 2660 1360 2000 3600 2140 1780 2660 3860 1900 940 1440 2560

80-450 3560 2840 2320 5120 2660 1360 2000 3600 2140 1780 2660 3860 1900 940 1440 2560

100-180 6220 4980 4100 8960 4600 2360 3520 6260 2840 2320 3560 5120 2660 1360 2000 3600

100-230 6220 4980 4100 8960 4600 2360 3520 6260 2840 2320 3560 5120 2660 1360 2000 3600

100-280 6220 4980 4100 8960 4600 2360 3520 6260 2840 2320 3560 5120 2660 1360 2000 3600

100-360 6220 4980 4100 8960 4600 2360 3520 6260 2840 2320 3560 5120 2660 1360 2000 3600

100-450 6220 4980 4100 8960 4600 2360 3520 6260 2840 2320 3560 5120 2660 1360 2000 3600

150-230 9780 7560 6220 13840 7060 3520 5160 9420 4980 4100 6220 8960 4600 2360 3520 6260

150-280 9780 7560 6220 13840 7060 3520 5160 9420 4980 4100 6220 8960 4600 2360 3520 6260

150-360 9780 7560 6220 13840 7060 3520 5160 9420 4980 4100 6220 8960 4600 2360 3520 6260

150-450 9780 7560 6220 13840 7060 3520 5160 9420 4980 4100 6220 8960 4600 2360 3520 6260

150-501 9780 7560 6220 13840 7060 3520 5160 9420 4980 4100 6220 8960 4600 2360 3520 6260

5 Installation at Site

RPH

23 of 76

Loading...

Loading...