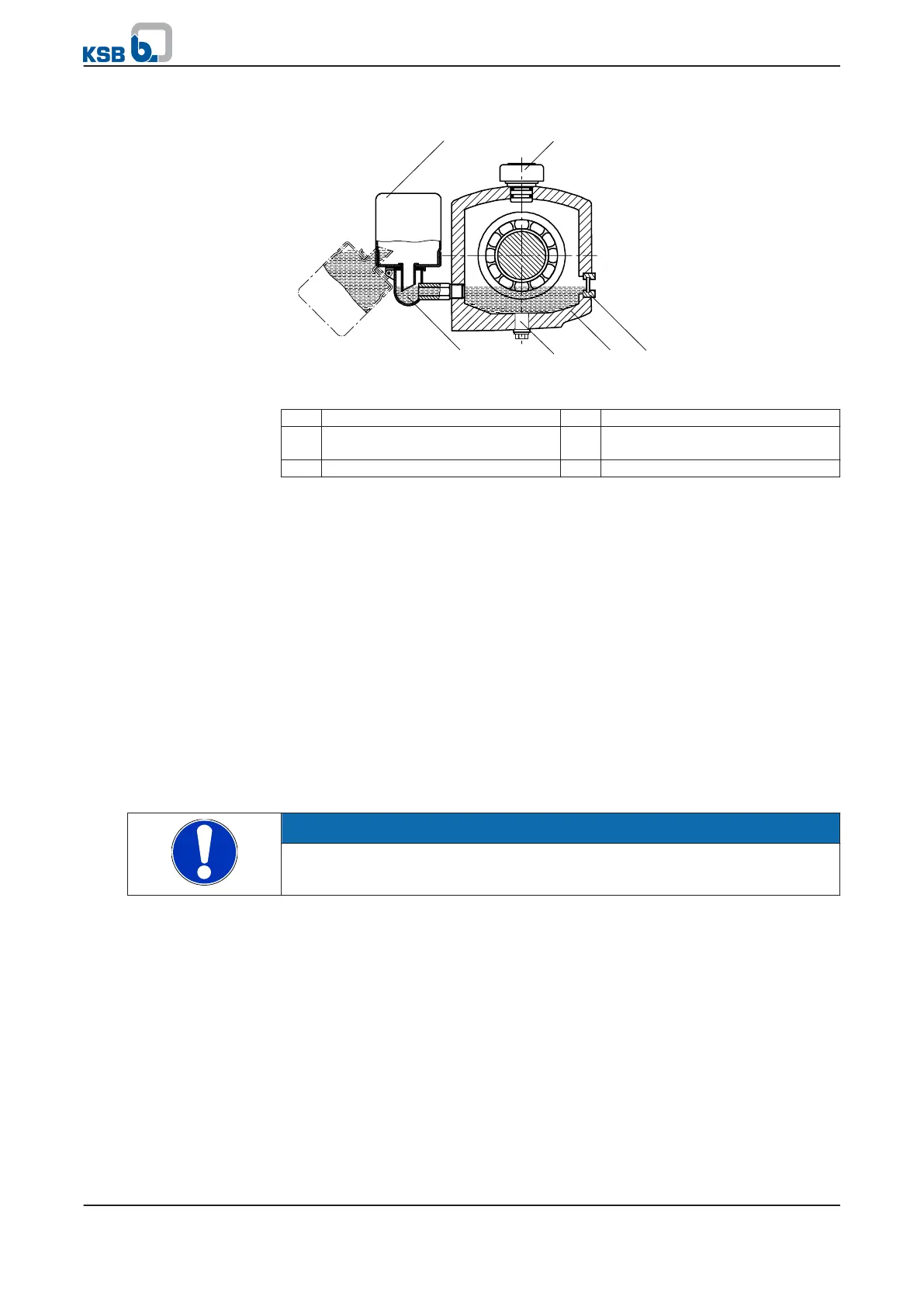

Fig. 11: Bearing bracket with constant level oiler

1 Constant level oiler 2 Vent plug

3 Connection elbow of the constant

level oiler

4 Screw plug

5 Bearing bracket 6 Oil level sight glass

1. Remove the protective cage.

2. Unscrew the vent plug (2).

3.

Hinge down the reservoir of the constant level oiler (1) from the bearing

bracket (5) and hold it in this position.

4. Fill in oil through the hole for the vent plug until the oil reaches the connection

elbow of the constant level oiler (3).

5. Completely fill the reservoir of the constant level oiler (1).

6. Snap the constant level oiler (1) back into its operating position.

7. Screw the vent plug (2) back in.

8. Fit the protective cage.

9. After approximately 5 minutes, check the oil level in the glass reservoir of the

constant level oiler (1).

The oil reservoir must be properly filled at all times to provide a constant oil

level. Repeat steps 1 - 8, if necessary.

10. To check the function of the constant level oiler (1), slowly drain some oil via

the screw plug (4) until air bubbles can be seen in the oil reservoir.

NOTE

An excessively high oil level can lead to a temperature rise and to leakage of the

fluid handled or oil.

6 Commissioning/Start-up/Shutdown

30 of 76

RPH

Loading...

Loading...