Designation Symbol to DIN

51502

Properties

Solidification point

(pour point)

-15 ℃

Application

temperature

13)

Higher than

permissible bearing

temperature

7.2.3.1.3 Oil quantity

Bearing bracket Oil quantity bearing bracket

[l]

B02 0.9

B03 1.8

B05 2.5

B06 5.7

B07 4.7

7.2.3.1.4 Changing the oil

WARNING

Lubricants posing a health hazard and/or hot lubricants

Hazard to persons and the environment!

▷ When draining the lubricant take appropriate measures to protect persons and

the environment.

▷ Wear safety clothing and a protective mask, if required.

▷ Collect and dispose of any lubricants.

▷ Observe all legal regulations on the disposal of fluids posing a health hazard.

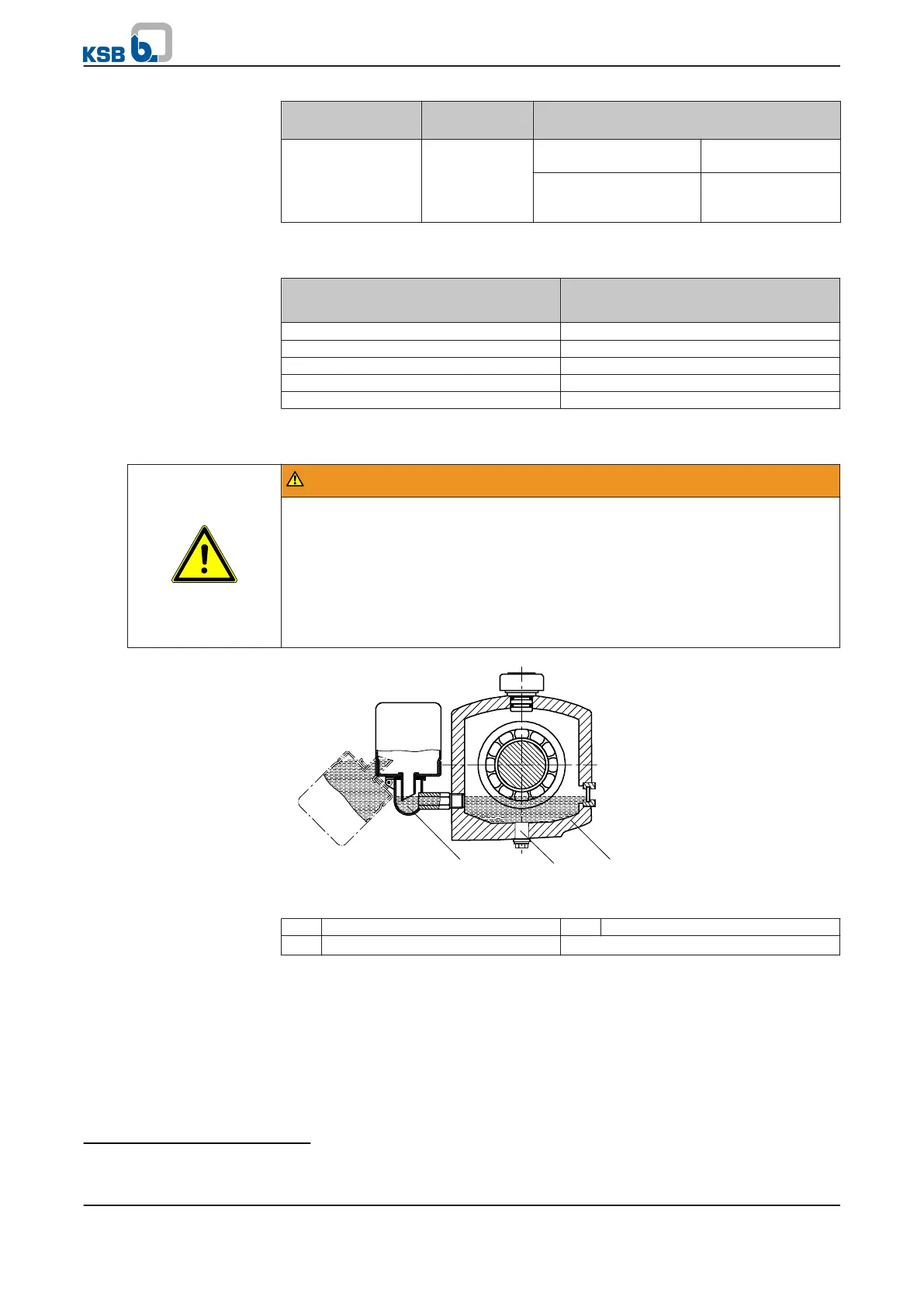

Fig. 13: Bearing bracket with constant level oiler

1 Constant level oiler 2 Screw plug

3 Bearing bracket

✓ A suitable container for the used oil is on hand.

1. Place the container underneath the screw plug.

2.

Undo the screw plug (2) at the bearing bracket (3) and drain the oil.

3. Once the bearing bracket (3) has been drained, re-insert and re-tighten the

screw plug (2).

4. Re-fill with oil.

13)

For ambient temperatures below -10 °C use a different suitable type of lubricating oil. Contact KSB.

7 Servicing/Maintenance

RPH

45 of 76

Loading...

Loading...