9

SHOCK

ABSORBER,

SWINGARM

81

•

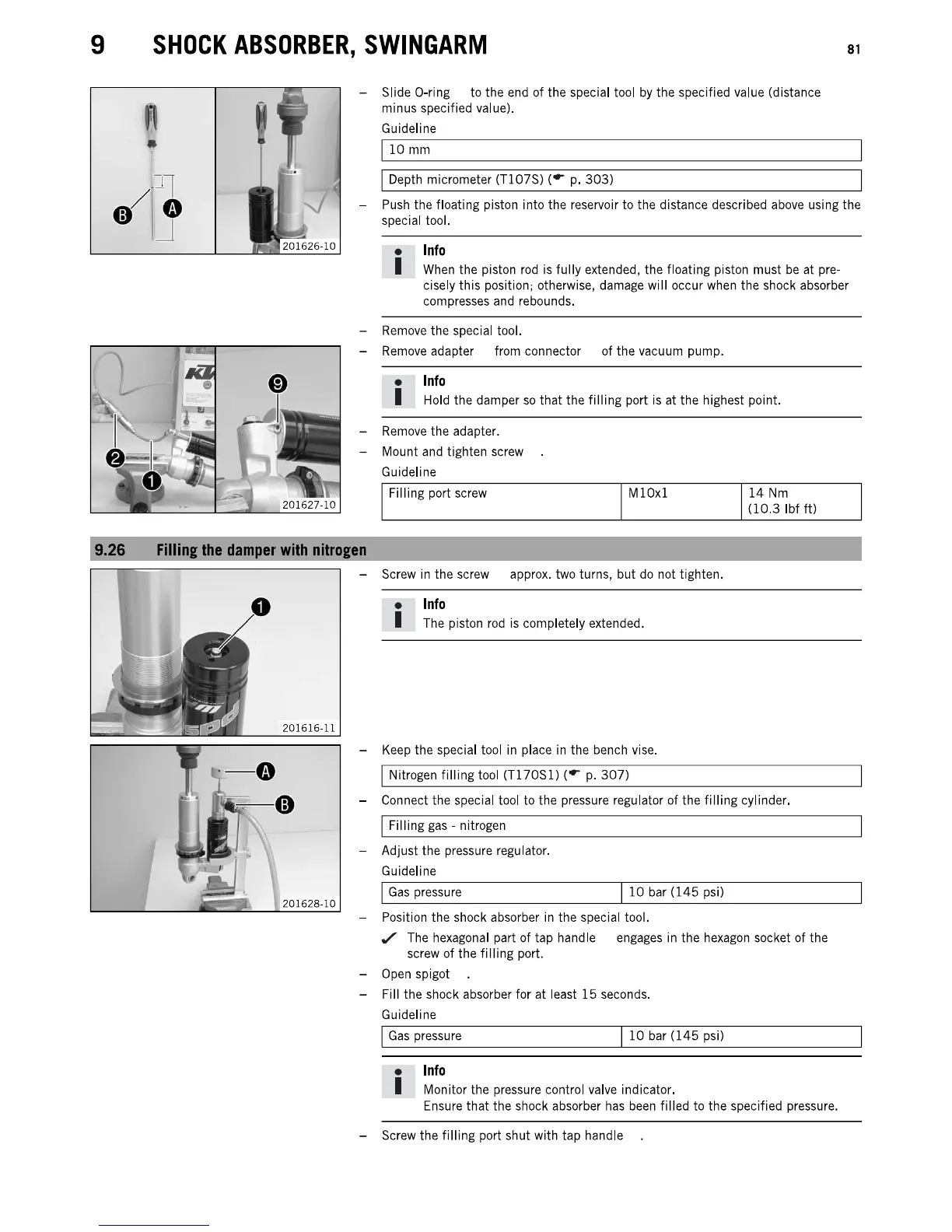

- Slide O-ring to the end of the special tool

by

the specified value (distance

minus specified value).

Guideline

110mm

I Depth micrometer

(TI07S)

(

..

p.

303)

-

Push

the floating piston into the reservoir to the distance described

above

using the

special tool.

•

Info

I

When

the piston

rod

is fully extended. the floating piston must

be

at pre-

cisely this position; otherwise. damage will occur

when

the shock absorber

compresses

and

rebounds.

-

Remove

the special tool.

-

Remove

adapter from connector of the vacuum pump.

•

Info

I Hold the damper

so

that the filling port is at the highest point.

-

Remove

the adapter.

- Mount and tighten screw

Guideline

Filling port screw

MI0xl

14

Nm

(10.3 Ibf

It)

9.28

FiIIi!.ll(

the

damp'er

with

nitra,en

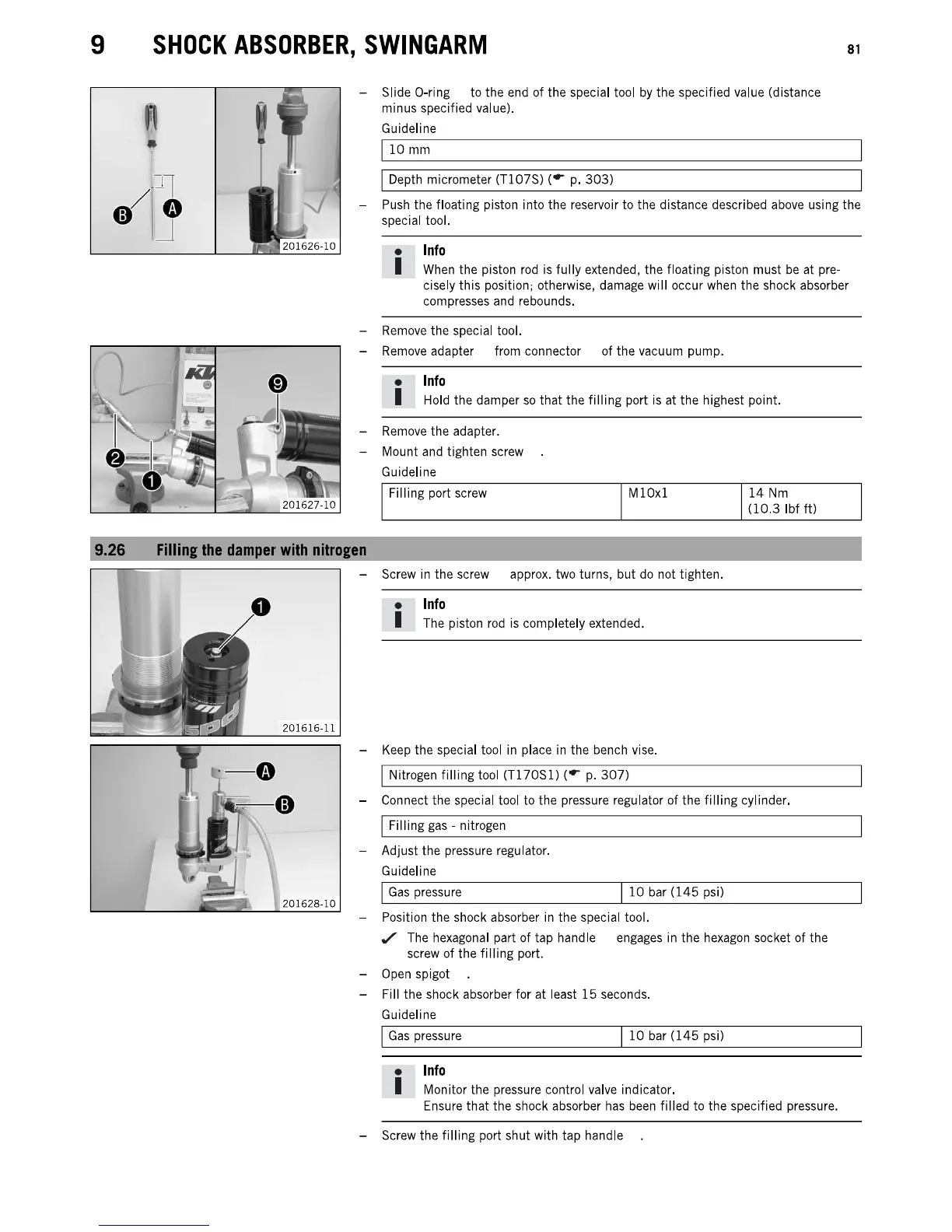

- Screw

in

the screw approx. two turns, but do not tighten.

•

Info

I The piston

rod

is completely extended.

-

Keep

the special tool

in

place

in

the bench vise.

I Nitrogen filling tool

(TI70S1)

(

..

p.

307)

Connect the special tool to the pressure regulator of the

filling

cylinder.

I Filling gas - nitrogen

- Adjust the pressure regulator.

Guideline

I

Gas

pressure

110

bar

(145

psi)

- Position the shock absorber

in

the special tool.

,/

The hexagonal part of tap handle

engages

in

the

hexagon

socket of the

screw of the

filling

port.

-

Open

spigot

- Fill the shock absorber for at least

15

seconds.

Guideline

I

Gas

pressure

110

bar

(145

psi)

•

Info

I Monitor the pressure control valve indicator.

Ensure that the shock absorber

has

been

filled to the specified pressure.

- Screw the

filling

port shut with tap handle

Loading...

Loading...