DIESEL

ENGINE

05

SERIES

WSM,

01640

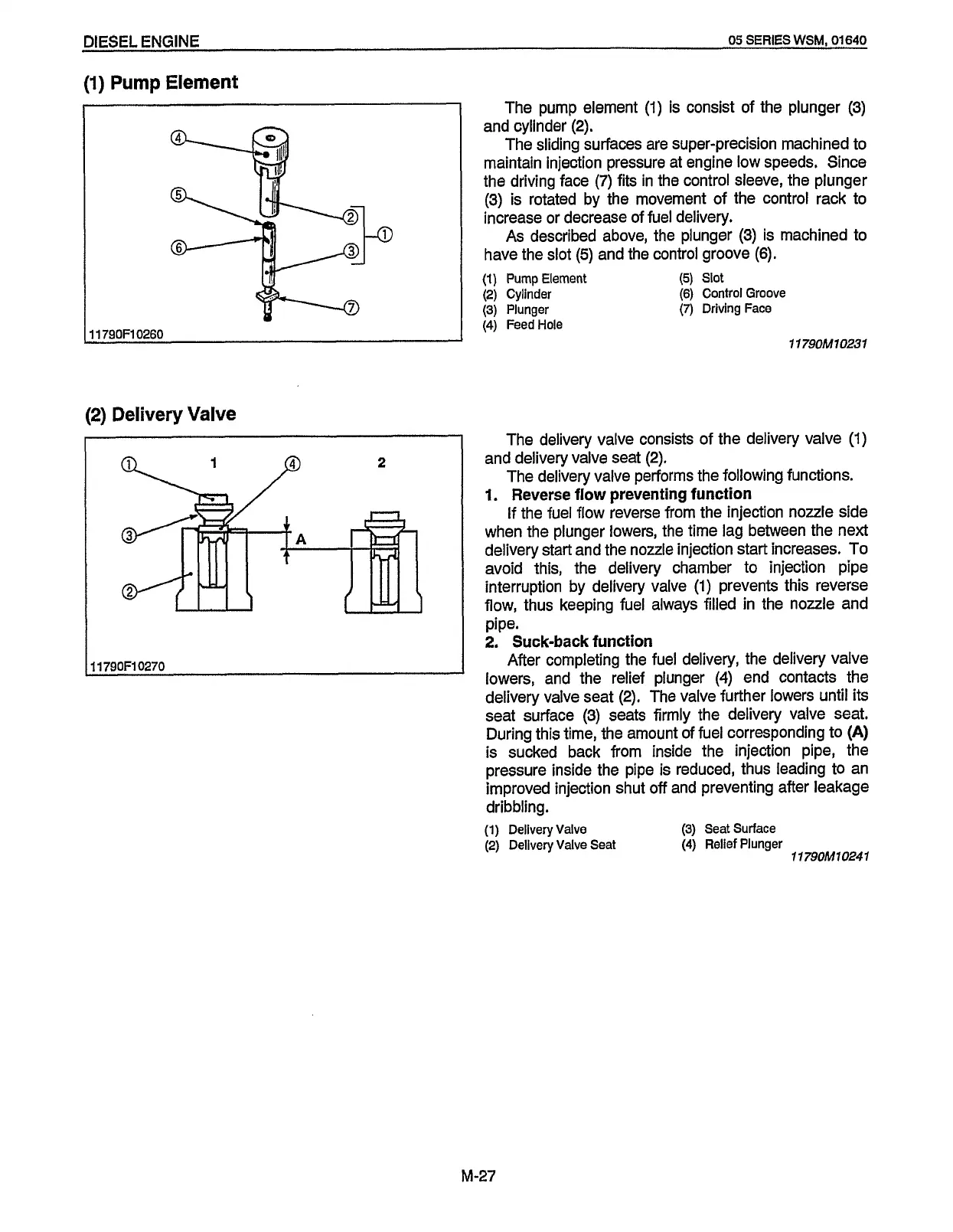

(1)

Pump

Element

I

1

1790F10260

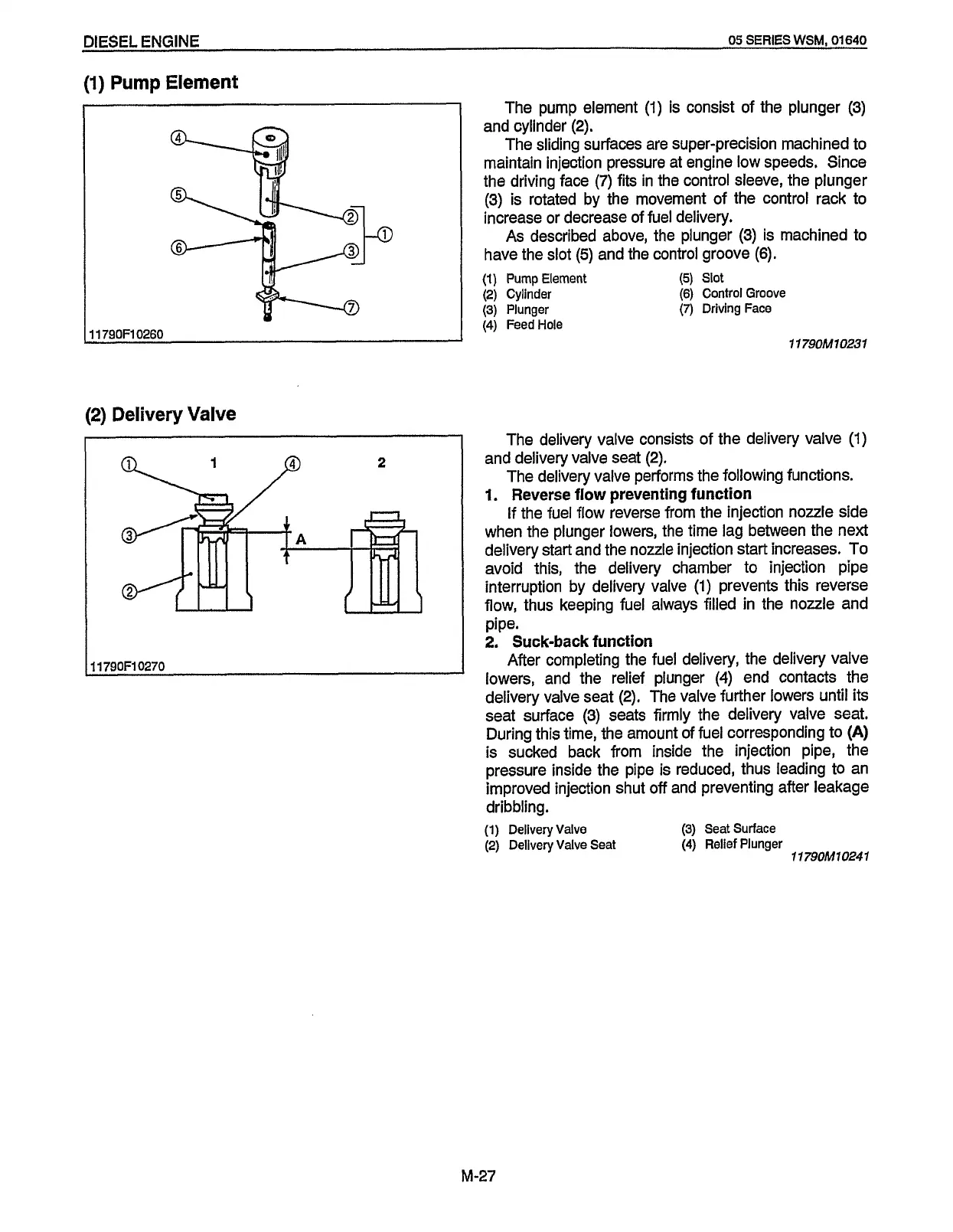

(2)

Delivery

Valve

a

2

11790F10270

The

pump

element

(1)

is

consist

of

the plunger

(3)

and cylinder

(2).

The

sliding

surfaces are super-precision machined to

maintain injection pressure at engine

low

speeds. Since

the

driving

face

(7)

fits

in

the

control

sleeve, the plunger

(3)

is rotated

by

the movement

of

the control rack to

increase

or

decrease

of

fuel delivery.

As described above, the plunger

(3)

is

machined to

have the

slot

(5)

and the control groove

(6).

(1)

Pump

Element

(5)

Slot

(2)

Cylinder

(6)

Control

Groove

(3)

Plunger

(7)

Driving

Face

(4)

Feed

Hole

1

1790M10231

The delivery valve consists

of

the delivery valve

(1)

and delivery valve seat

(2).

The delivery valve performs the

following

functions.

1.

Reverse

flow

preventing function

If

the fuel

flow

reverse

from

the injection nozzle side

when the plunger lowers, the time lag between

the

next

delivery start and the nozzle injection start increases.

To

avoid this, the delivery chamber to injection pipe

interruption

by

delivery valve

(1)

prevents

this

reverse

flow,

thus keeping fuel always filled

in

the

nozzle

and

pipe.

2.

Suck-back function

After completing the fuel delivery, the delivery valve

lowers, and the relief plunger

(4)

end contacts the

delivery valve seat

(2).

The valve further lowers

until

its

seat surface

(3)

seats

firmly

the delivery valve seat.

During

this

time, the amount

of

fuel corresponding

to

(A)

is

sucked back

from

inside the injection pipe, the

pressure inside the pipe

is

reduced, thus leading

to

an

improved injection

shut

off

and preventing after leakage

dribbling.

(1)

Delivery

Valve

(2)

Delivery

Valve

Seat

(3)

Seat

Surface

(4)

Relief

Plunger

11

790M1024

1

M-27

Redistribution or publication of this document,

by any means, is strictly prohibited.

Loading...

Loading...