DIESEL ENGINE

05

SERIES

WSM,

01640

d6

11900F10180

I

I//

I

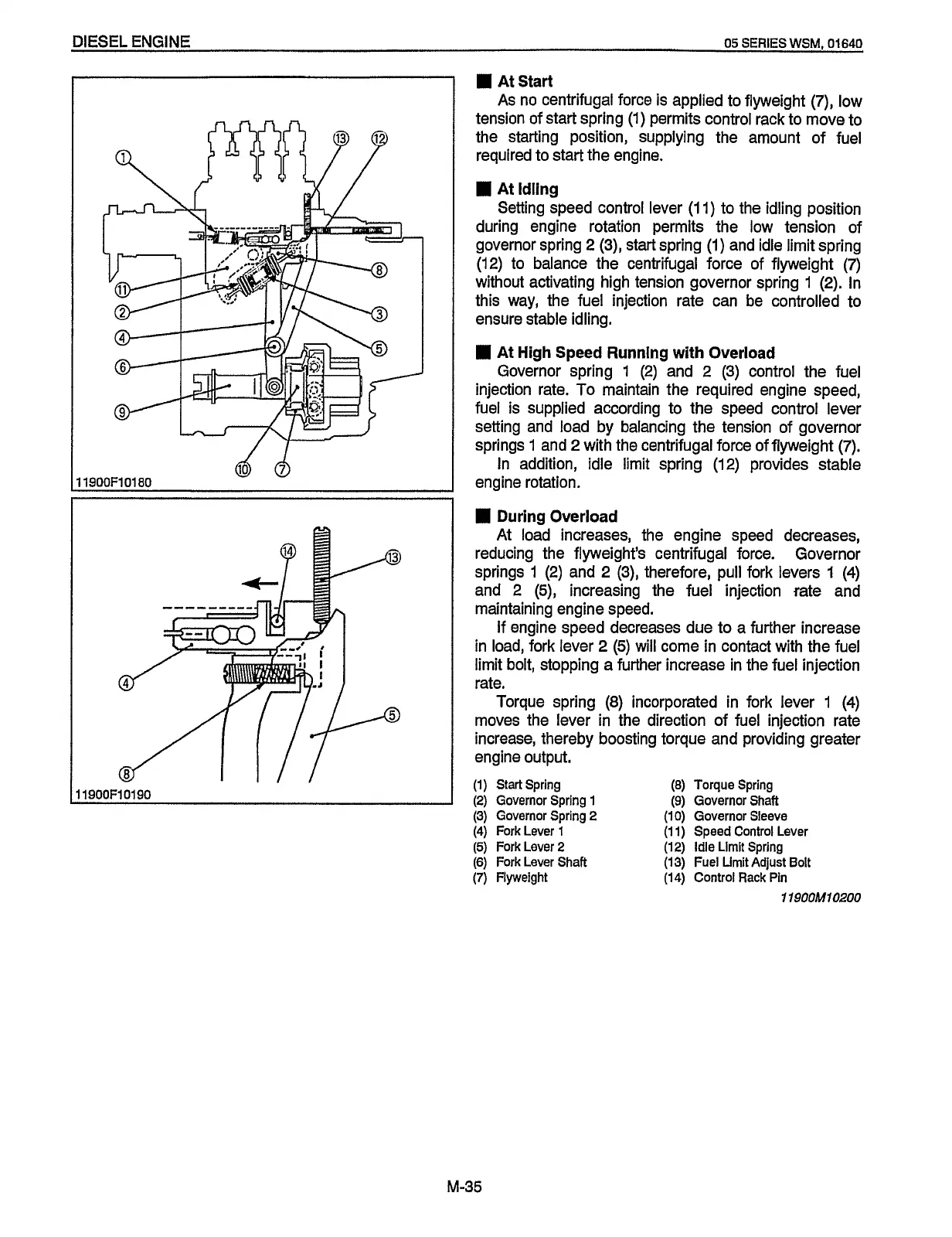

At Start

As

no centrifugal force is applied to flyweight

(7),

low

tension

of

start spring

(1)

permits control rack to move to

the starting position, supplying the amount of fuel

required to start the engine.

I

At Idling

Setting speed control lever (1 1) to the idling position

during engine rotation permits the low tension of

governor spring 2

(3),

start spring (1) and idle limit spring

(12) to balance the centrifugal force of flyweight

(7)

without activating high tension governor spring

1

(2). In

this way, the fuel injection rate can be controlled to

ensure stable idling.

I

At

High

Speed Running with Overload

Governor spring 1 (2) and

2

(3) control the fuel

injection rate.

To

maintain the required engine speed,

fuel is supplied according to the speed control lever

setting and load by balancing the tension

of

governor

springs

1

and

2

with the centrifugal force of flyweight

(7).

In addition, idle limit spring (12) provides stable

engine rotation.

I

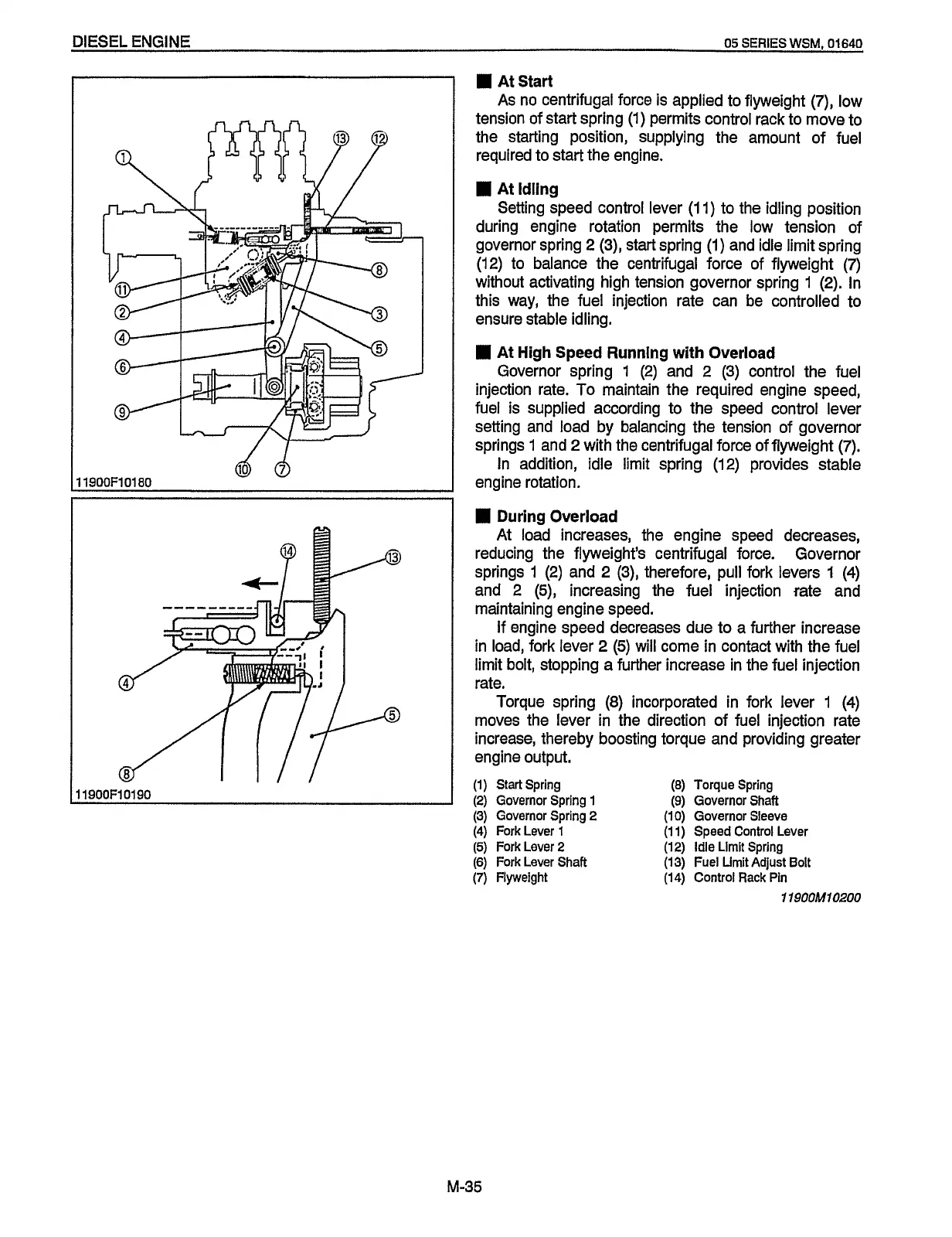

During Overload

At load increases] the engine speed decreases,

reducing the flyweight’s centrifugal force. Governor

springs

1

(2)

and

2

(3), therefore, pull fork levers

1

(4)

and 2

(5),

increasing the fuel injection rate and

maintaining engine speed.

If

engine speed decreases due to a further increase

in load, fork lever

2

(5)

will

come in contact with the fuel

limit bolt, stopping a further increase in the fuel injection

rate.

Torque spring

(8) incorporated in fork lever 1 (4)

moves the lever in the direction of fuel injection rate

increase] thereby boosting torque and providing greater

engine output.

(1)

Start

Spring

(8)

Torque Spring

(2)

Governor Spring

1

(9)

Governor

Shaft

(3)

Governor Spring

2

(1

0)

Governor Sleeve

(4)

Fork Lever 1 (1

1)

Speed Control

Lever

(5)

Fork

Lever

2

(12) Idle

Llmlt

Spring

(6)

Fork Lever Shaft (13) Fuel

Limit

Adjust

Bolt

(7)

Flyweight

(14)

Control Rack Pin

11900M10200

M-35

Redistribution or publication of this document,

by any means, is strictly prohibited.

Loading...

Loading...