S-59

WG972-E2, DF972-E2, WSM

GASOLINE / LPG ENGINE

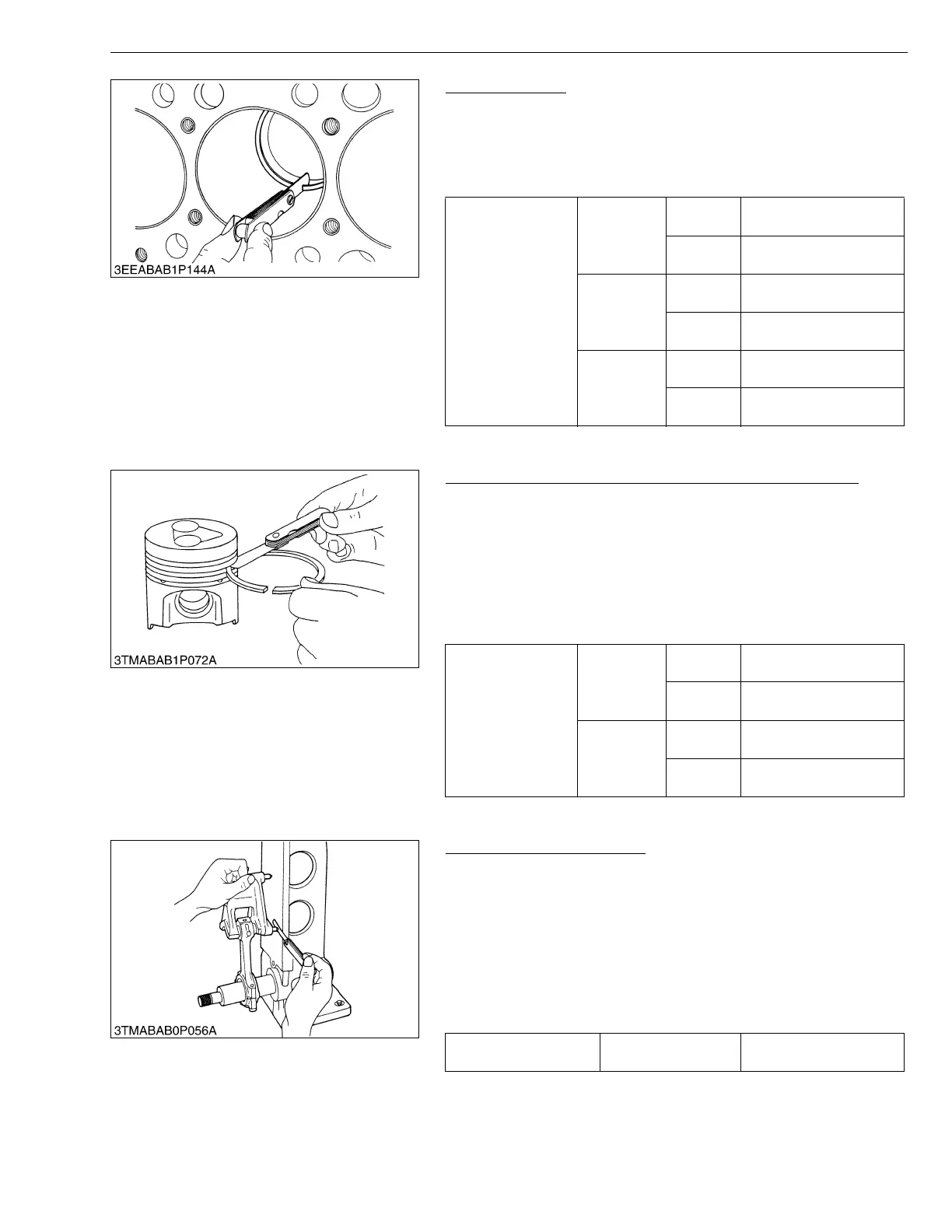

Piston Ring Gap

1. Insert the piston ring into the lower part of the cylinder (the least

worn out part) with a piston ring compressor and piston.

2. Measure the ring gap with a feeler gauge.

3. If the measurement exceeds the allowable limit, replace the

piston ring.

W1146671

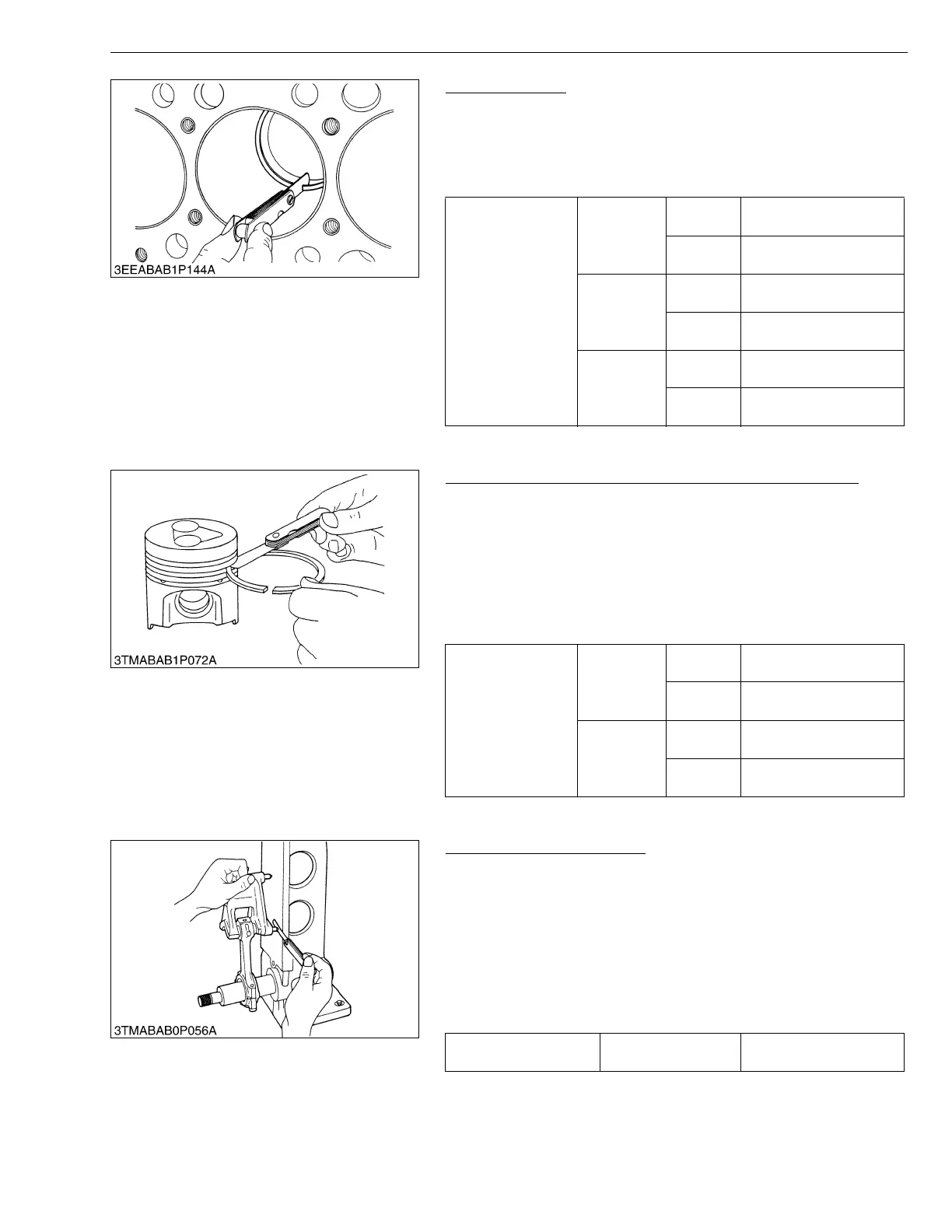

Clearance between Piston Ring and Piston Ring Groove

1. Clean the rings and the ring grooves, and install each ring in its

groove.

2. Measure the clearance between the ring and the groove with a

thickness gauge.

3. If the clearance exceeds the allowable limit, replace the piston

ring.

4. If the clearance still exceeds the allowable limit with new ring,

replace the piston.

W1148550

Connecting Rod Alignment

1. Remove the crankpin bearing, and install the connecting rod cap.

2. Install the piston pin in the connecting rod.

3. Install the connecting rod on the connecting rod alignment tool.

4. Put a gauge over the piston pin, and move it against the face

plate.

5. If the gauge does not fit squarely against the face plate, measure

the space between the pin of the gauge and the face plate.

6. If the measurement exceeds the allowable limit, replace the

connecting rod.

W1031462

Piston ring gap

Top ring

Factory

spec.

0.15 to 0.35 mm

0.0059 to 0.0138 in.

Allowable

limit

1.25 mm

0.0492 in.

Second ring

Factory

spec.

0.30 to 0.45 mm

0.0118 to 0.0177 in.

Allowable

limit

1.25 mm

0.0492 in.

Oil ring

Factory

spec.

0.20 to 0.70 mm

0.0079 to 0.0276 in.

Allowable

limit

1.25 mm

0.0492 in.

Clearance between

piston ring and

piston ring groove

Top ring

Second ring

Factory

spec.

0.080 to 0.120 mm

0.00315 to 0.00472 in.

Allowable

limit

0.15 mm

0.0059 in.

Oil ring

Factory

spec.

0.065 to 0.10 mm

0.0026 to 0.0039 in.

Allowable

limit

0.15 mm

0.0059 in.

Space between gauge

pin face plate

Allowable limit

0.05 mm

0.0020 in.

Loading...

Loading...