M-18

WG972-E2, DF972-E2, WSM

GASOLINE / LPG ENGINE

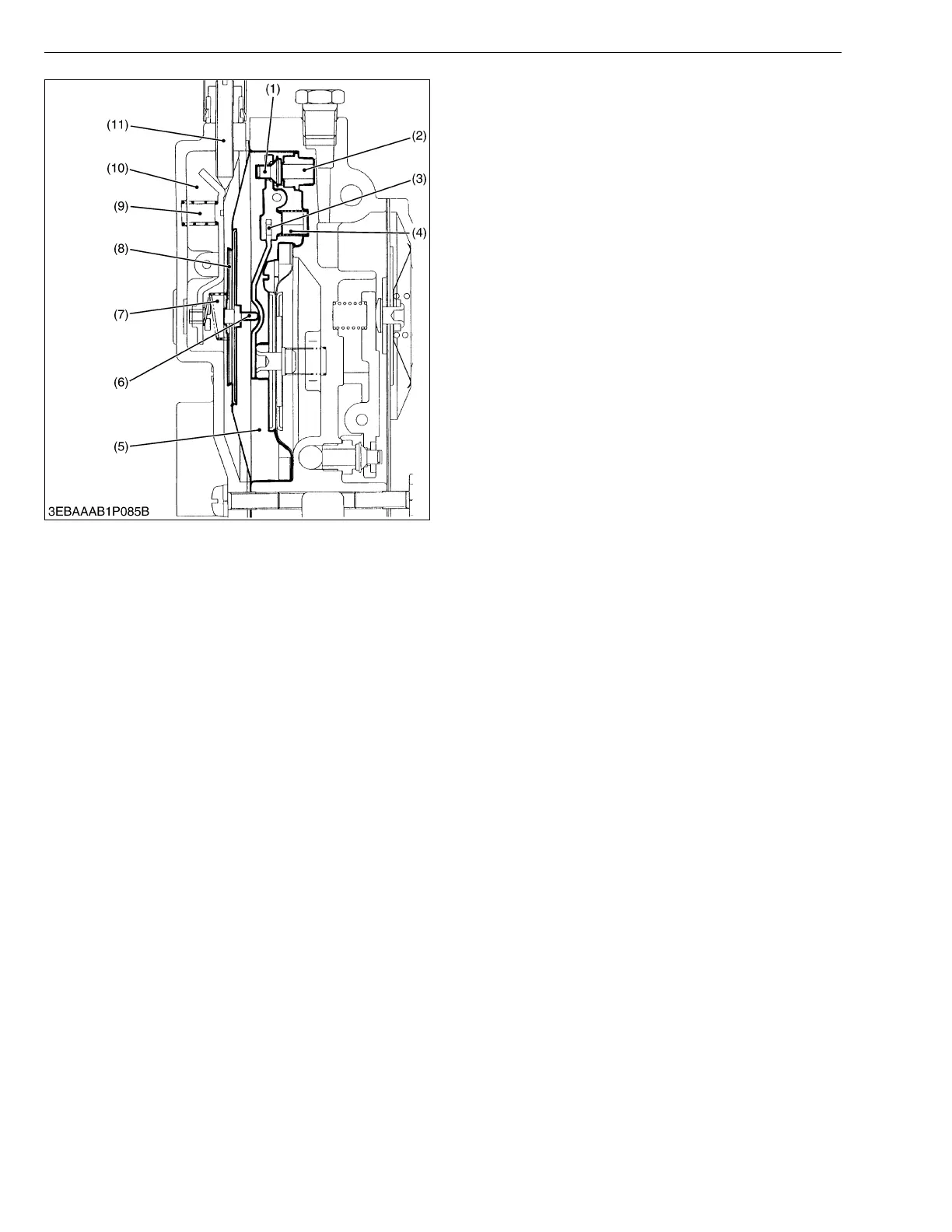

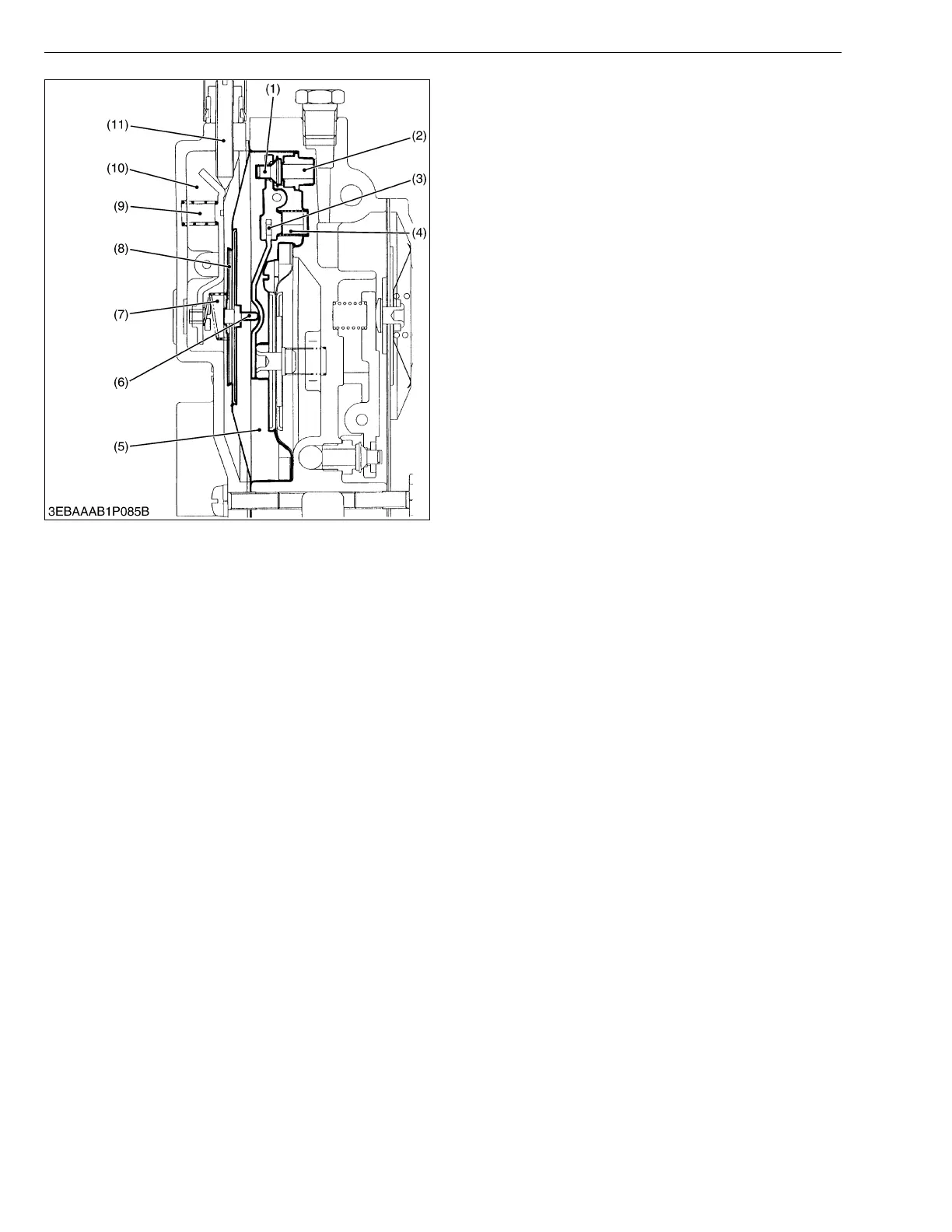

■ Secondary Chamber

The fuel adjusted with primary chamber to the

specified pressure enters secondary chamber (5)

between secondary valve (1) and the valve seat (2) and

is decompressed to the vicinity of the atmospheric

pressure almost.

A secondary valve is assembled to a part of the

secondary valve lever (3) supported to body and is shut

by the tension of the spring of a secondary valve spring

(4).

A secondary diaphragm pin (6) touches the edge

besides this lever (3).

The one side of secondary diaphragm (8) is faced in

secondary chamber and the other side faces

atmosphere chamber (10).

When the engine stops, the atmospheric pressure is

led in secondary chamber and a secondary valve is shut

by the tension of a secondary valve spring.

When the engine rotates, the negative pressure is

generated in the venturi tube of the mixer.

As for this negative pressure, working secondary

diaphragm (8) is pulled to the second chamber side by

the difference pressure with atmosphere chamber by

second chamber.

Do the push up of the secondary valve lever (3) by

this working, secondary valve is opened, and the fuel

flows in.

When pressure in chamber rises by the fuel which

flows in, the diaphragm is pushed to the atmosphere

chamber side and narrows the opening of the valve and

decreases the supply of the fuel.

Secondary chamber is almost maintained in the

atmospheric pressure by the thing to repeat such

working.

W1014568

(1) Secondary Valve

(2) Valve Seat

(3) Secondary Valve Lever

(4) Secondary Valve Lever

Spring

(5) Secondary Chamber

(6) Diaphragm Pin

(7) Balance Spring

(8) Secondary Diaphragm

(9) Balance Lever Spring

(10) Atmosphere Chamber

(11) Idle Adjust Screw

Loading...

Loading...