S-49

V3300-E2B, V3300-T-E2B, WSM

DIESEL ENGINE

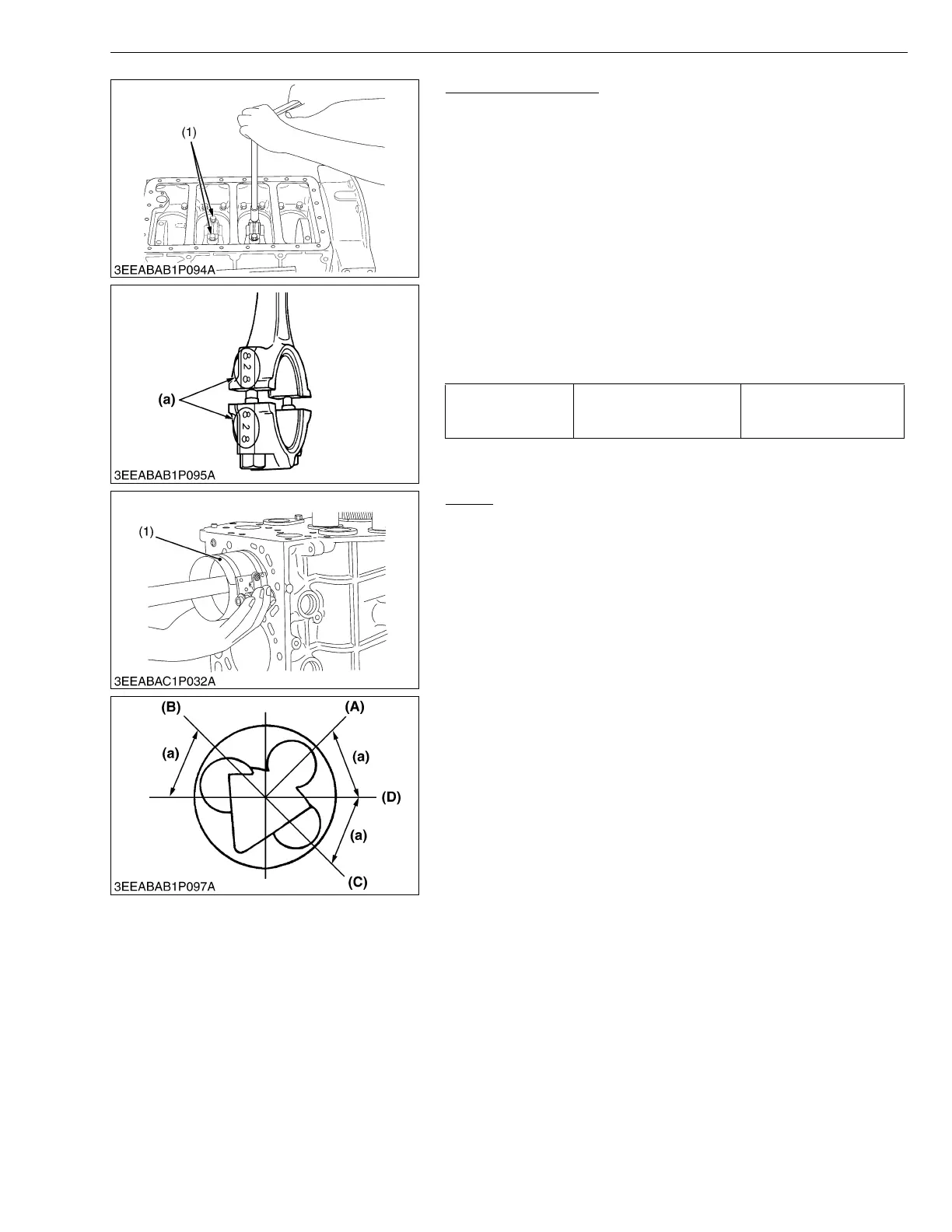

Connecting Rod Cap

1. Remove the connecting rod screws (1) from connecting rod cap.

2. Remove the connecting rod caps.

(When reassembling)

•Align the marks (a) with each other. (Face the marks toward the

injection pump.)

• Apply engine oil to the connecting rod screws and lightly screw it

in by hand, then tighten it to the specified torque.

If the connecting rod screw won’t be screwed in smoothly, clean

the threads.

If the connecting rod screw is still hard to screw in, replace it.

• When using the existing crank pin metal again, put tally marks on

the crank pin metal and the connecting rod in order to keep their

positioning.

• Fit the crank pin metal in place : its centrally groove side toward

the connecting rod, and the non-grooved side toward the cap.

W1058252

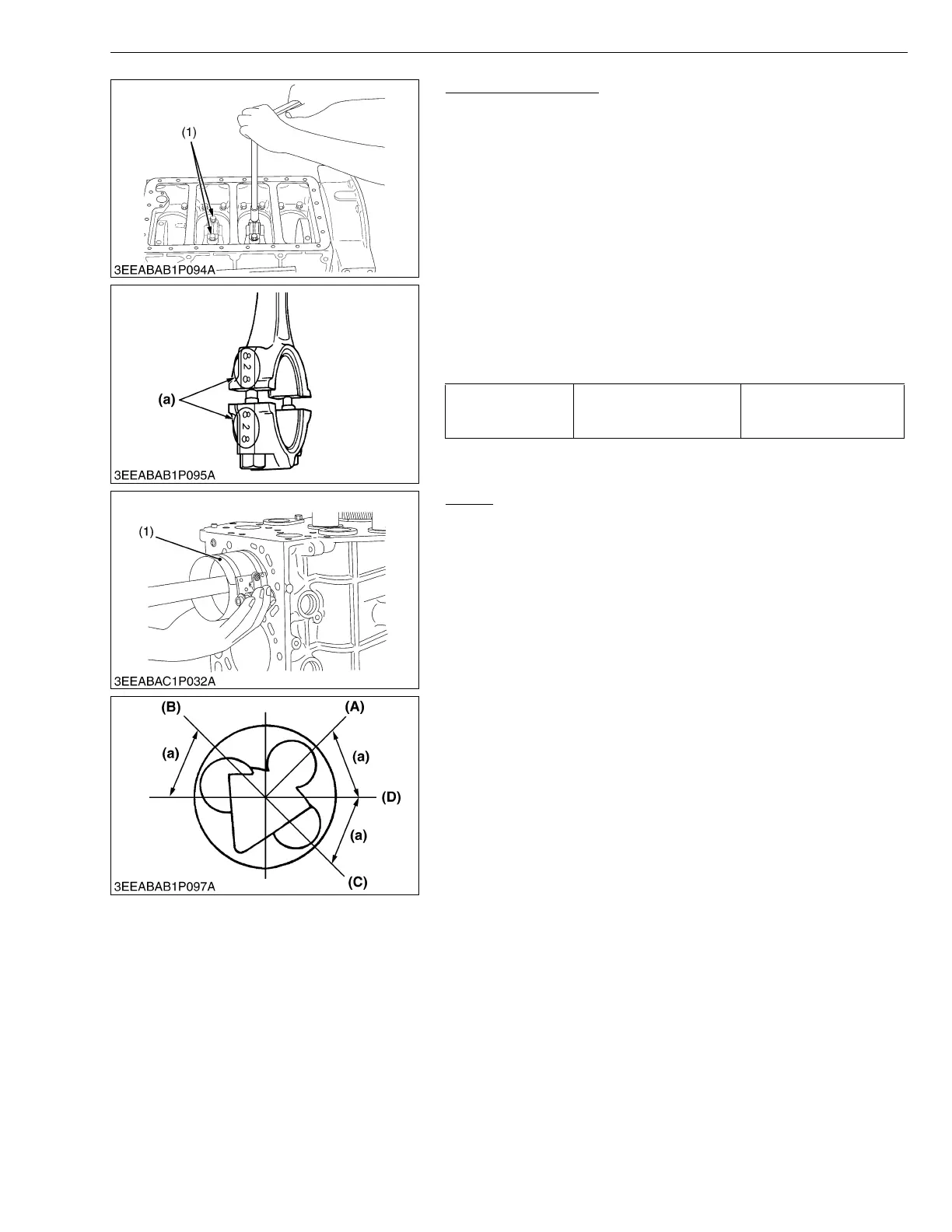

Piston

1. Turn the flywheel and set a piston to the top dead center.

2. Pull out the piston upward by lightly tapping it from the bottom of

the crankcase with the grip of a hammer.

(When reassembling)

• Before inserting the piston into the cylinder, apply enough engine

oil to the cylinder.

• When inserting the piston into the cylinder, face the mark on the

connecting rod to the injection pump.

• Do not change the combination of cylinder and piston.

Make sure of the position of each piston by marking. For

example, mark “1” on the No. 1 position.

• When inserting the piston into the cylinder, place the gap of

the top ring on the opposite side of the combustion chamber

and stagger the gaps of the second ring and oil ring marking

a right angle from the gap of the top ring.

• Carefully insert the pistons using a piston ring compressor

(1). Otherwise, their chrome-plated section may be

scratched, causing trouble inside the liner.

W1058433

Tightening torque Connecting rod screw

78.5 to 83.4 N·m

8.0 to 8.5 kgf·m

57.9 to 61.5 ft-lbs

(1) Connecting Rod Screw (a) Mark

(1) Piston Ring Compressor

(a) 0.79 rad (45 °)

(A) Top Ring Gap

(B) Second Ring Gap

(C) Oil Ring Gap

(D) Piston Pin Hole

Loading...

Loading...