S-68

V3300-E2B, V3300-T-E2B, WSM

DIESEL ENGINE

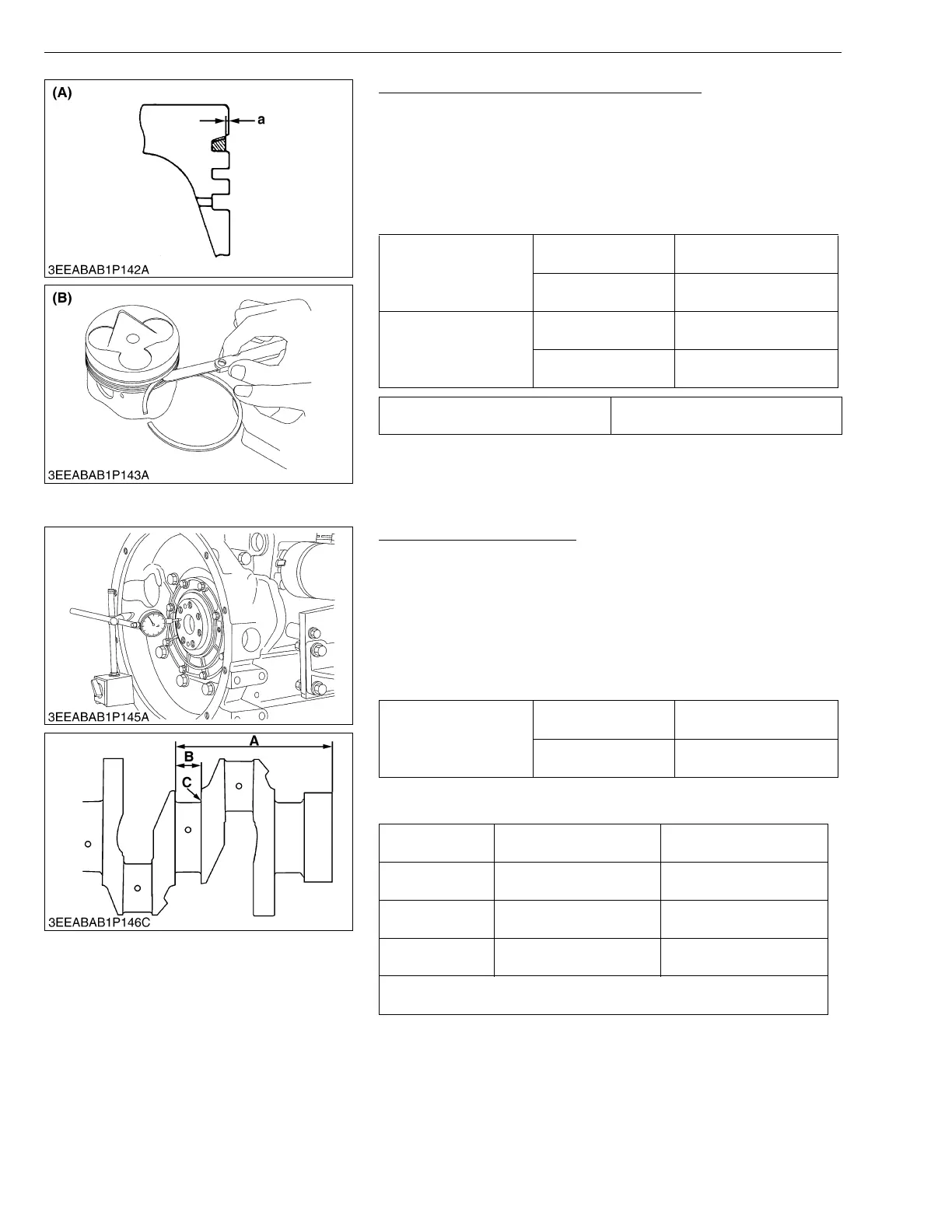

Clearance between Piston Ring and Groove

1. Remove carbon from the ring grooves.

2. Measure the clearance between the ring and the groove with a

feeler gauge or depth gauge.

3. If the clearance exceeds allowable limit, replace the ring since

compression leak and oil shortage result.

4. If the clearance still exceeds the allowable limit after replacing the

ring, replace the piston.

W1066183

(4) Crankshaft

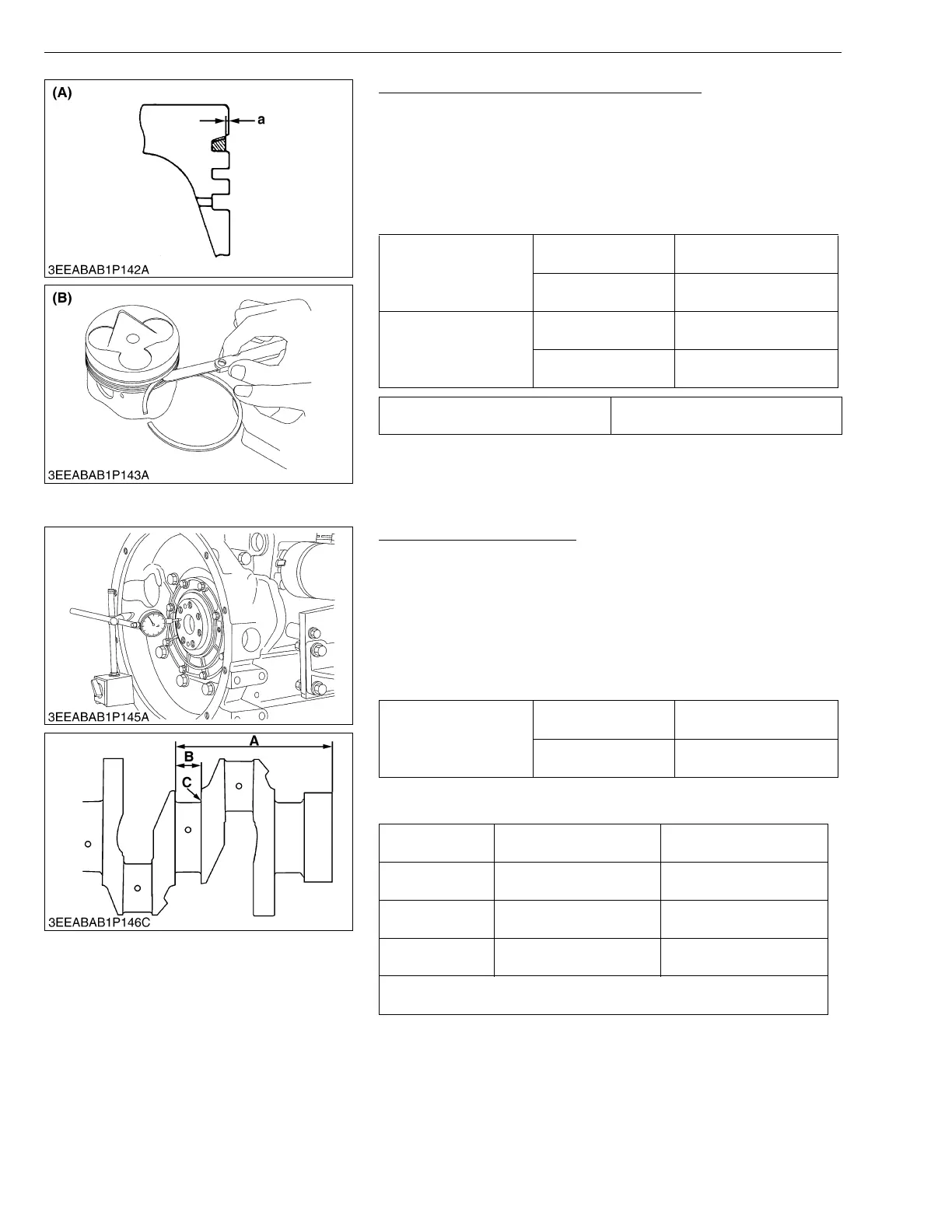

Crankshaft Side Clearance

1. Set a dial indicator with its tip on the end of the crankshaft.

2. Measure the side clearance by moving the crankshaft to the front

and rear.

3. If the measurement exceeds the allowable limit, replace the

thrust bearings.

4. If the same size bearing is useless because of the crankshaft

journal wear, replace it with an oversize one referring to the table

and figure.

(Reference)

• Oversize dimensions of crankshaft journal.

W1066738

Factory spec.

Second ring

0.093 to 0.120 mm

0.0037 to 0.0047 in.

Oil ring

0.020 to 0.060 mm

0.0008 to 0.0023 in.

Allowable limit

Second ring

0.20 mm

0.0079 in.

Oil ring

0.15 mm

0.0059 in.

Factory specification : a

More than 0.2 mm

0.079 in.

(A) Top Ring (Key Stone Type) (B) 2nd, Oil Ring

Crankshaft side

clearance

Factory spec.

0.15 to 0.31 mm

0.0059 to 0.0122 in.

Allowable limit

0.50 mm

0.0197 in.

Oversize

0.2 mm

0.008 in.

0.4 mm

0.016 in.

Dimension A

169.1 to 169.15 mm

6.6575 to 6.6594 in.

169.2 to 169.25 mm

6.6614 to 6.6634 in.

Dimension B

29.20 to 29.25 mm

1.1496 to 1.1515 in.

29.40 to 29.45 mm

1.1574 to 1.1594 in.

Dimension C

2.8 to 3.2 mm radius

0.1102 to 0.1260 in. radius

2.8 to 3.2 mm radius

0.1102 to 0.1260 in. radius

(0.8S)

The crankshaft journal must be fine-finished to higher than ∇∇∇∇.

Loading...

Loading...