S-69

V3300-E2B, V3300-T-E2B, WSM

DIESEL ENGINE

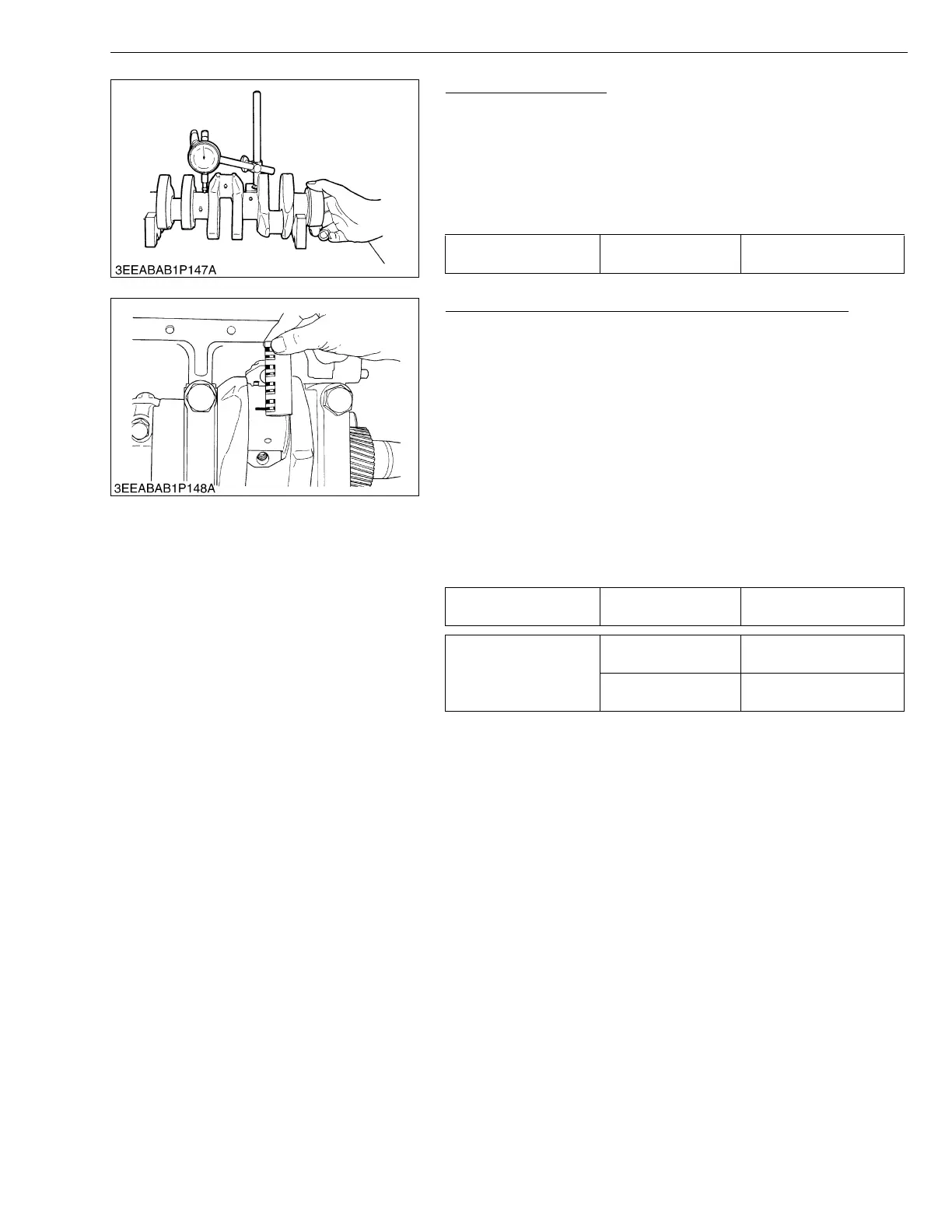

Crankshaft Alignment

1. Support the crankshaft with V block on the surface plate and set

a dial indicator with its tip on the intermediate journal at right

angle.

2. Rotate the crankshaft on the V block and get the misalignment

(half of the measurement).

3. If the misalignment exceeds the allowable limit, replace the

crankshaft.

W1067285

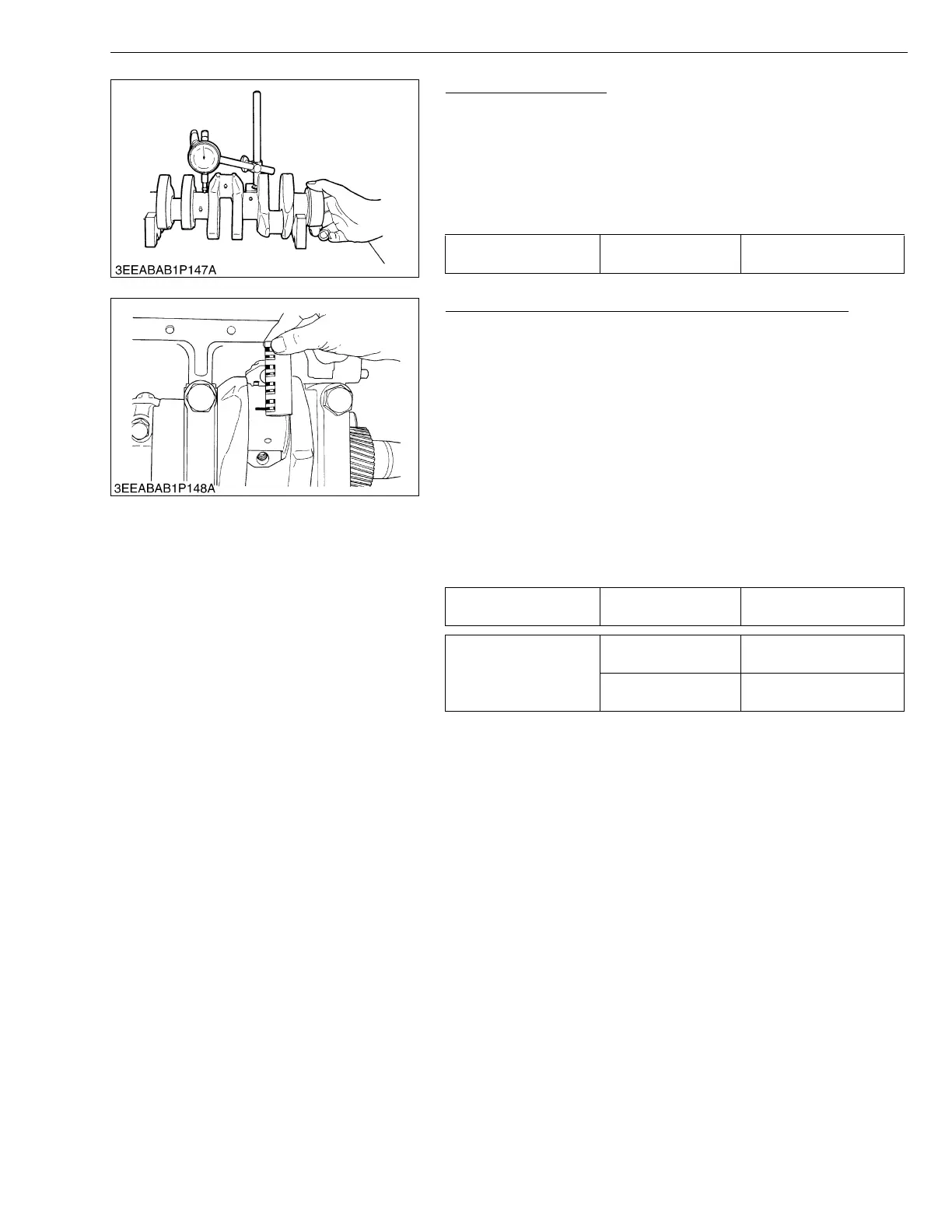

Oil Clearance between Crankpin and Crankpin Bearing

1. Clean the crankpin and crankpin bearing.

2. Put a strip of plastigage on the center of the crankpin.

3. Install the connecting rod cap and tighten the connecting rod

screws to the specified torque, and remove the cap again.

4. Measure the amount of the flattening with the scale, and get the

oil clearance.

5. If the oil clearance exceeds the allowable limit, replace the

crankpin bearing.

6. If the same size bearing is useless because of the crankpin wear,

replace it with an undersize one referring to the table and figure.

• Never insert the plastigage into the crankpin oil hole.

• Be sure not to move the crankshaft while the connecting rod

screws are tightened.

W1067389

Crankshaft alignment Allowable limit

0.02 mm

0.00079 in.

Crankpin O.D. Factory spec.

52.977 to 52.990 mm

2.0857 to 2.0862 in.

Oil clearance between

crankpin and crankpin

bearing

Factory spec.

0.018 to 0.051 mm

0.0007 to 0.0020 in.

Allowable limit

0.20 mm

0.0079 in.

Loading...

Loading...