M-3

V3300-E2B, V3300-T-E2B, WSM

DIESEL ENGINE

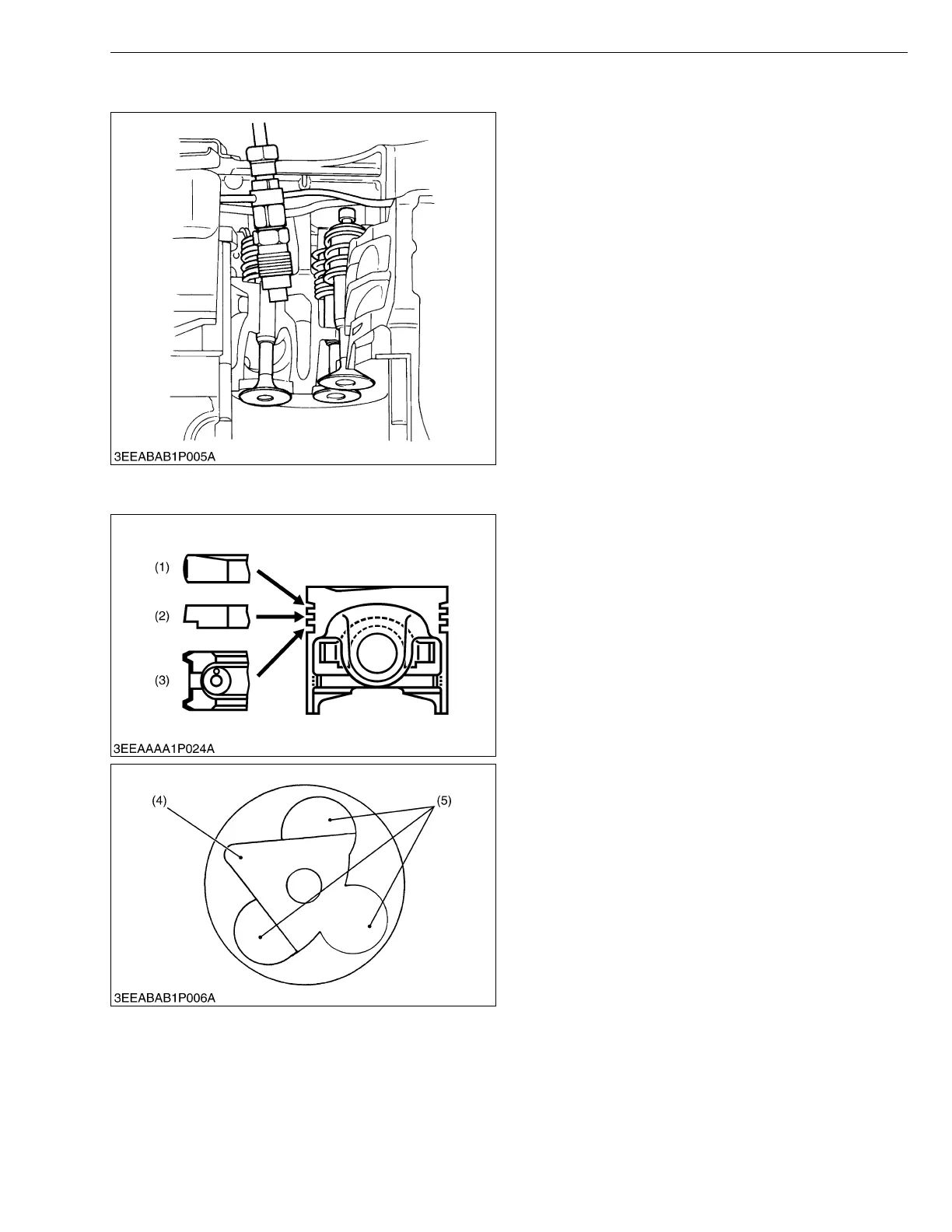

[3] CYLINDER HEAD

This engine employs three valve system - two inlet

valves and double ports, and one exhaust valve which

produce good inlet inertia to improve combustion

efficiency and volumetric efficiency. It also employs

Kubota’s unique combustion chamber with multiple

injection grooves.

Besides the conventional cross port system, it

employs the forced cooling method between valves to

eliminate heat distortion, thus enabling durable and

reliable configuration.

W1013336

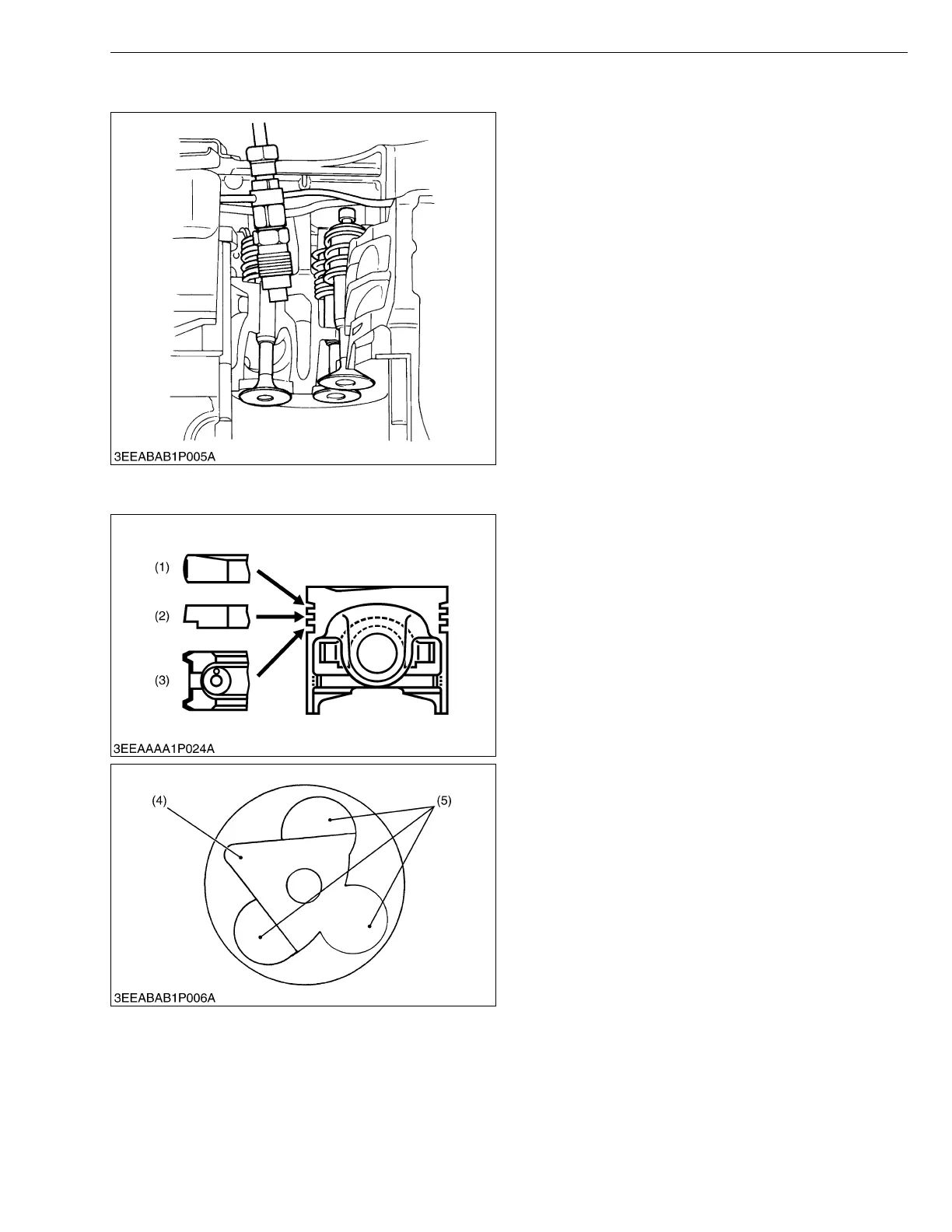

[4] PISTON AND PISTON RINGS

This engine employs the E-TVCS VERSION-II so that

the improved combustion surface at the top of piston

enables more complete combustion efficiency than the

conventional models.

The profile and the offset of piston are optimized to

reduce slapping noises. The oil jet at the small end of the

connecting rod reduces heat load of the piston.

Three rings are installed in grooves in the piston. The

top ring (1) is made of nitrizing steel to get more reliability

than the chrome plated ring. It is a keystone type ring to

get durability against heavy load. At the sliding part, a

special piston ring which is conformable to the cylinder

wall is employed. The second ring is chromeplated on

the peripheral surface and it is an undercut ring to

prevent shortage of oil.

The oil ring (3) has chamfered contact faces and an

expander ring, which increase the pressure of the oil ring

against the cylinder wall.

Several grooves are cut on the topland to help heat

dissipate and to prevent scuffing.

W1013501

(1) Top Ring

(2) Second Ring

(3) Oil Ring

(4) Depression

(5) Valve Recess

Loading...

Loading...