S-71

V3300-E2B, V3300-T-E2B, WSM

DIESEL ENGINE

Oil Clearance between Crankshaft Journal and Crankshaft

Bearing

1. Clean the crankshaft journal and crankshaft bearing.

2. Put a strip of press gauge on the center of the journal.

• Never insert the press gauge into the oil hole of the journal.

3. Install the main bearing case and tighten the screws to the

specified torque, and remove the cases again.

4. Measure the amount of the flattening with the scale and get the

oil clearance.

5. If the clearance exceeds the allowable limit, replace the

crankshaft bearing.

(Reference)

• Undersize dimensions of crankshaft journal.

W1069159

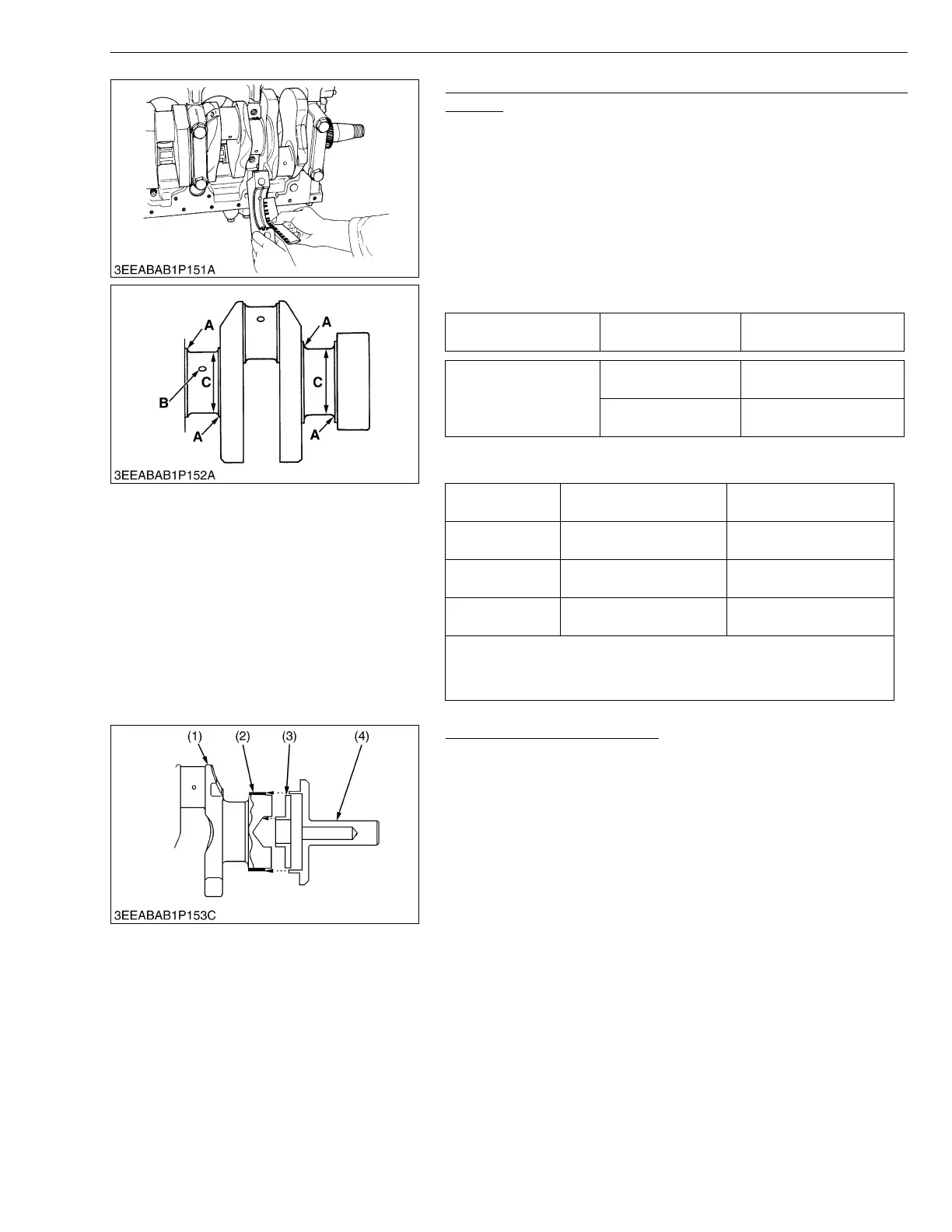

Replacing Crankshaft Sleeve

1. Remove the used crankshaft sleeve (2).

2. Set the sleeve guide (3) to the crankshaft (1).

3. Heat a new sleeve to a temperature between 150 to 200 °C (302

to 392 °F), and fix the sleeve to the crankshaft as shown in figure.

4. Press fit the sleeve using the auxiliary socket for pushing (4).

• Mount the sleeve with its largely chamfered surface facing

outward.

W1069911

Crankshaft journal O.D. Factory spec.

74.977 to 74.990 mm

2.9518 to 2.9524 in.

Oil clearance between

crankshaft journal and

crankshaft bearing

Factory spec.

0.018 to 0.062 mm

0.0007 to 0.0024 in.

Allowable limit

0.20 mm

0.0079 in.

Undersize

0.2 mm

0.008 in.

0.4 mm

0.016 in.

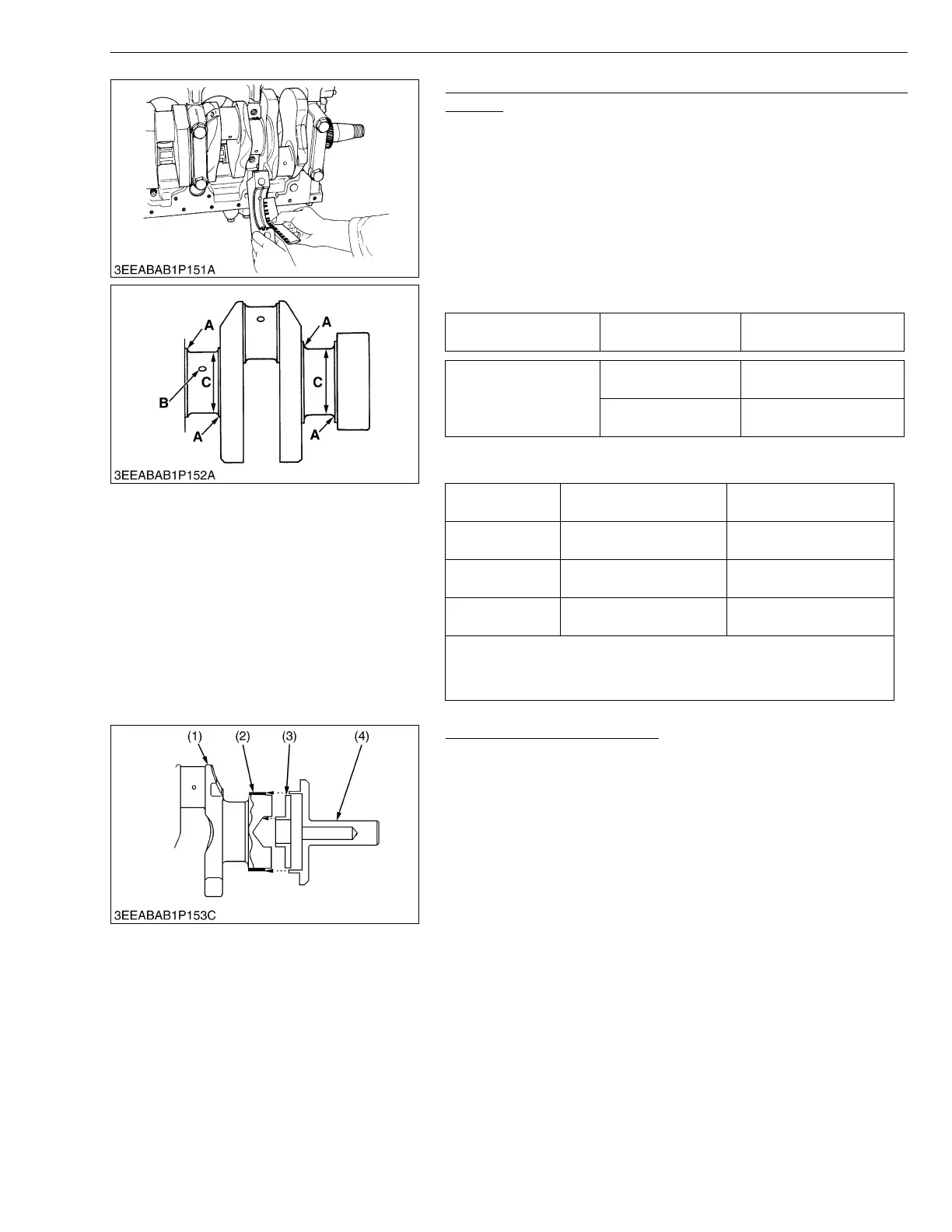

Dimension A

2.8 to 3.2 mm radius

0.1102 to 0.1260 in. radius

2.8 to 3.2 mm radius

0.1102 to 0.1260 in. radius

*Dimension B

1.0 to 1.5 mm relief

0.0394 to 0.0591 in. relief

1.0 to 1.5 mm relief

0.0394 to 0.0591 in. relief

Dimension C

74.777 to 74.790 mm dia.

2.9440 to 2.9445 in. dia.

74.577 to 74.590 mm dia.

2.9361 to 2.9366 in. dia.

(0.8S)

The crankshaft journal must be fine-finished to higher than ∇∇∇∇.

*Holes to be de-burred and edges rounded with 1.0 to 1.5 mm

(0.0394 to 0.0591 in.) relief.

(1) Crankshaft

(2) Crankshaft Sleeve

(3) Sleeve Guide

(4) Auxiliary Socket for Pushing

Loading...

Loading...