ECM SYSTEM

WG1605-G-E3,WG1605-L-E3,WG1605-GL-E3, DM

1-87

REPAIR OF WIRING HARANESS

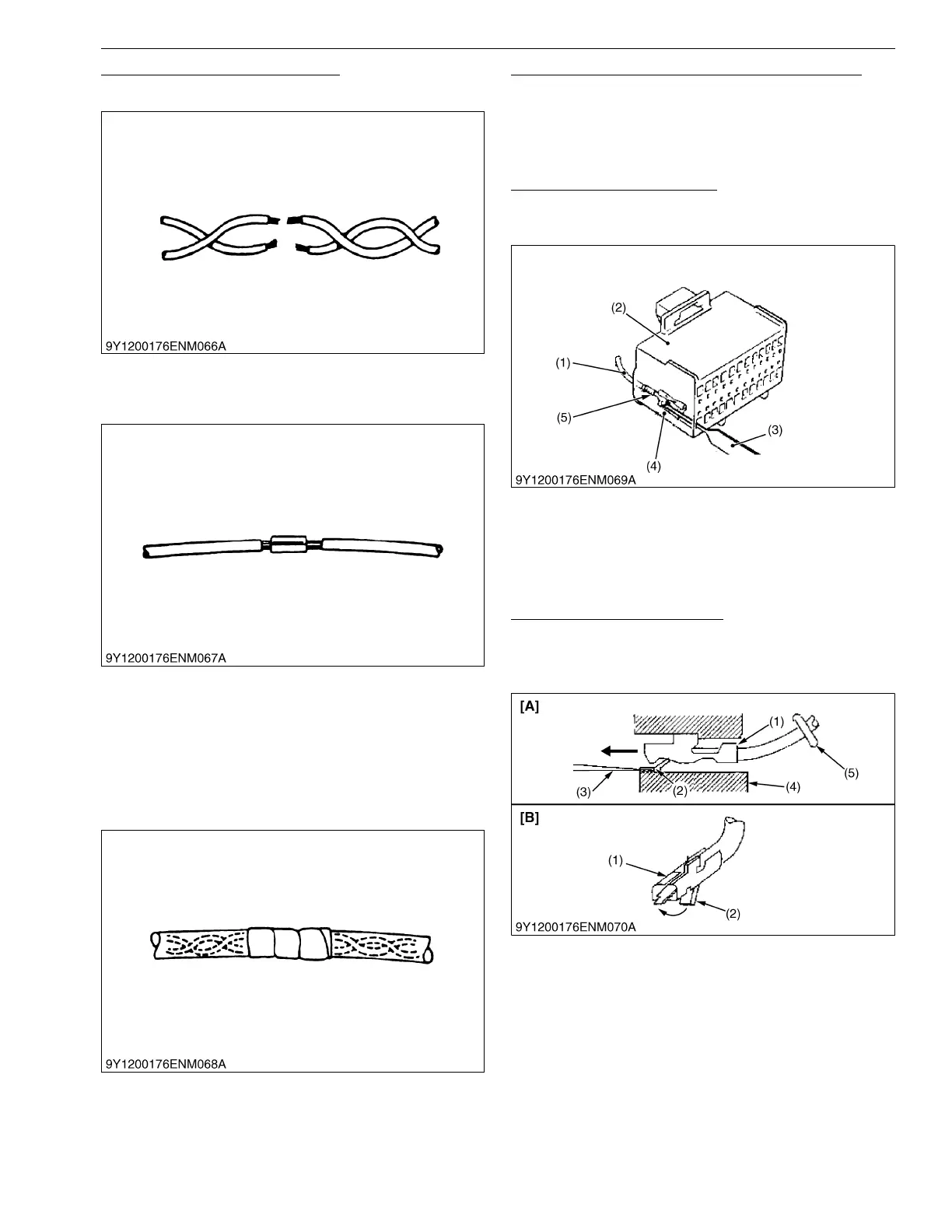

TWISTED LEADS

1. Locate the damaged wire remove only sufficient

insulation to allow for a complete sealing of the wire

in the connector splice.

2. Place a proper sized heat shrink tube over one of the

cut end and slide back from the splice area.

3. position each of the stripped wire ends into the splice

and ensure there is no bare wire exposed.

4. Solder the connection using a Rosin Core solder

5. Slide the heat shrink tube over the splice and use

heat to shrink the tube over the connection to create

a water tight seal.

6. Re-twist the wire and secure the splice are with

electrical tape to tightly seal the area.

CONNECTOR END REPAIR OR REPLACEMENT

Before making a connector repair, be certain of the

type of connector for example Weather-Pack connectors

and Compact Three connectors look very similar but are

service differently.

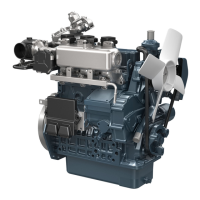

MICRO-PACK CONNECTOR

Refer to Figure 2 for the repair procedure for the

repair of a MICRO-PACK connector

Figure 23: MICRO PACK CONNECTOR REPAIR

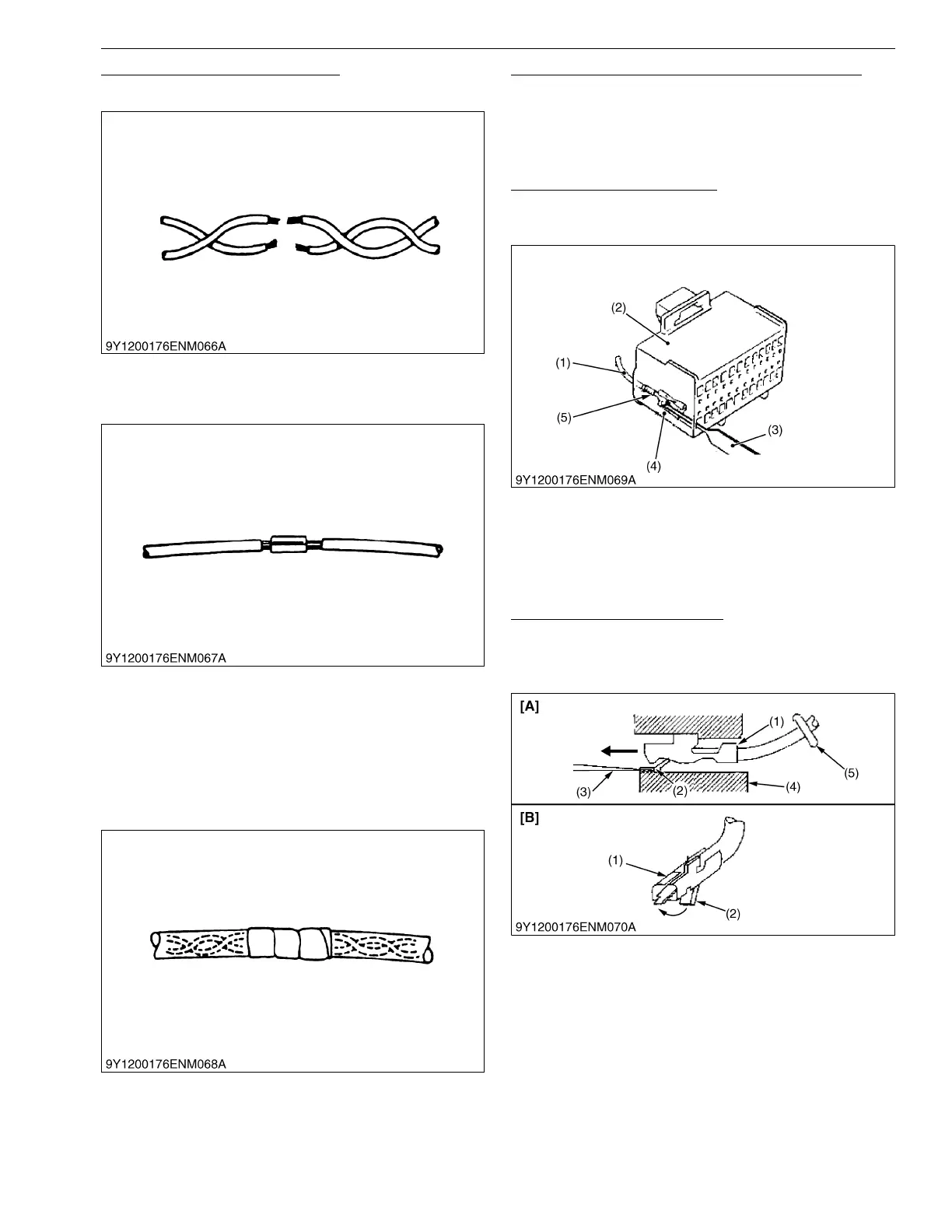

METRI-PACK CONNECTORS

Some electrical connectors on the harness may

utilize a METRI-PACK connector. Refer to Figure 3 for

removal and repair of the terminal.

Figure 24: METRI-PACK Terminal Repair

(1) Connector Housing

(2) Cable

(3) Pin Removal Tool J33095,

BTB234-A

(4) Locking Tang

(5) Terminal

(1) METRI-PACK Series 150

Female Terminal

(2) Locking Tang

(3) Tool J35689, or Bt-8446

(4) Connector Body

(5) Seal

[A] Cut image of connector

[B] End of Wire harness

Loading...

Loading...