S-16

05-E3B, 05-E3BG, WSM

DIESEL ENGINE

4. CHECKING, DISASSEMBLING AND SERVICING

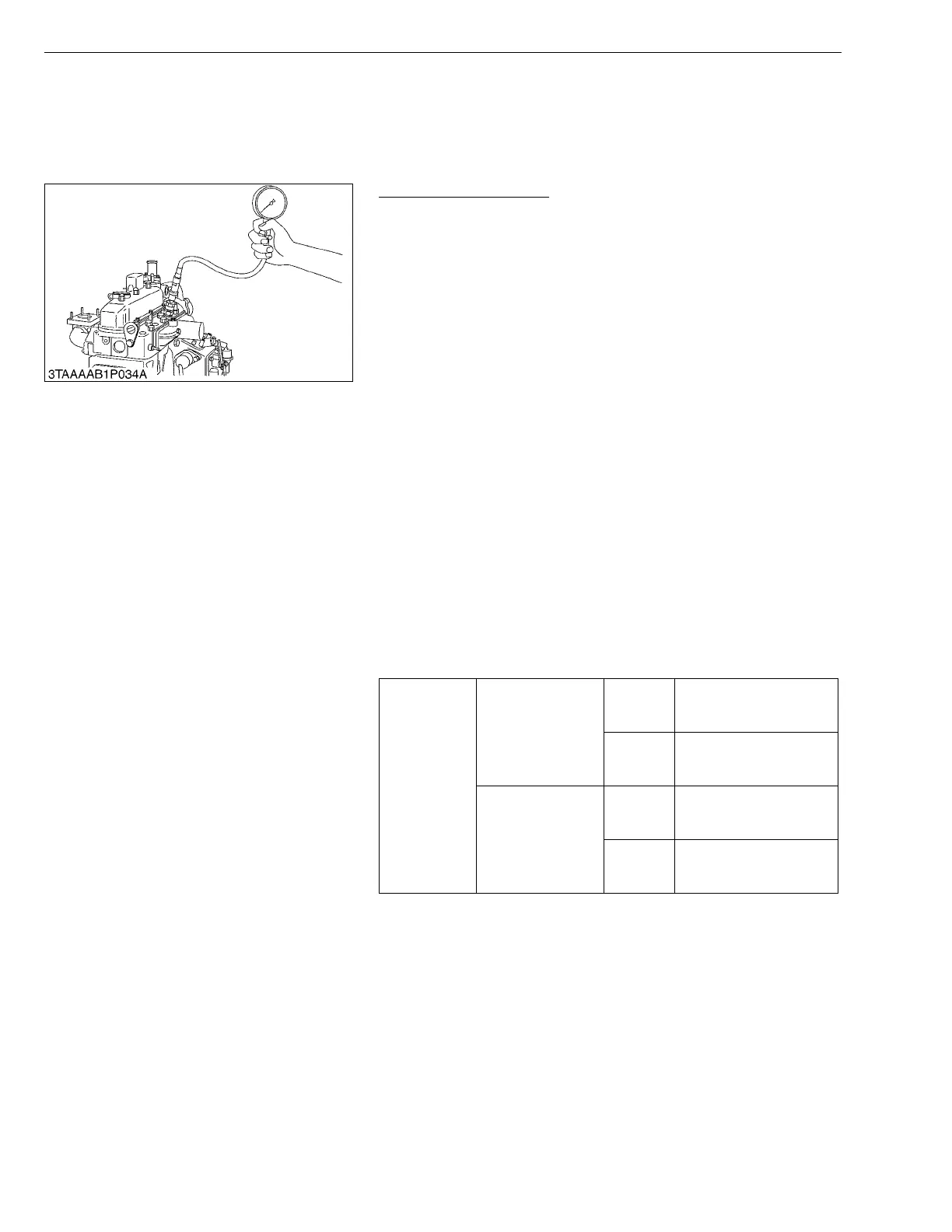

[1] CHECKING AND ADJUSTING

(1) Engine Body

Compression Pressure

1. Run the engine until it is warmed up.

2. Stop the engine.

3. Remove the air cleaner, the muffler and all glow plugs (or

nozzles).

4. Set a compression tester with the adaptor to the glow plug hole

(or nozzle hole).

Nozzle hole : Adaptor H (07909-31231)

Glow plug hole : Adaptor L (07909-31301)

5. After making sure that the stop lever is set at the stop position

(non-injection), run the engine with the starter and measure the

compression pressure.

6. Repeat steps 4 and 5 for each cylinder.

7. If the measurement is below the allowable limit, apply a small

amount of oil to the cylinder wall through the glow plug hole (or

nozzle hole) and measure the compression pressure again.

8. If the compression pressure is still less than the allowable limit,

check the top clearance, valve clearance and cylinder head.

9. If the compression pressure increases after applying oil, check

the cylinder wall and piston rings.

• Check the compression pressure with the specified valve

clearance.

• Always use a fully charged battery for performing this test.

• Variances in cylinder compression values should be under

10 %.

W10178940

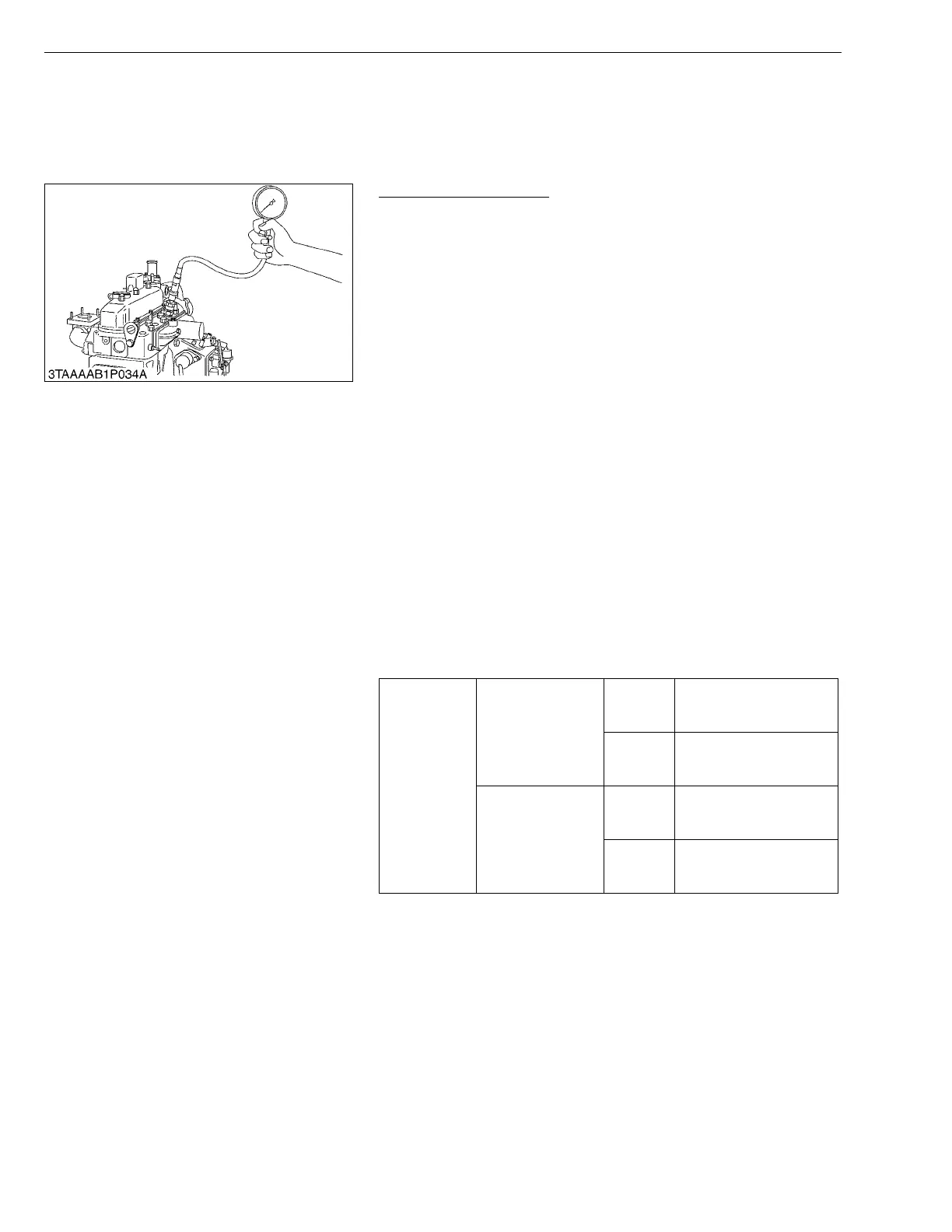

Compression

pressure

D1005-E3B / E3BG

D1105-E3B / E3BG

D1305-E3B / E3BG

V1505-E3B / E3BG

Factory

spec.

3.73 to 4.11 MPa

38.0 to 42.0 kgf/cm

2

541 to 597 psi

Allowable

limit

2.26 MPa

23.0 kgf/cm

2

327 psi

D1105-T-E3B

V1505-T-E3B

Factory

spec.

3.14 to 3.53 MPa

32.0 to 36.0 kgf/cm

2

456 to 512 psi

Allowable

limit

2.26 MPa

23.0 kgf/cm

2

327 psi

Loading...

Loading...