31

UK

TECHNICAL FEATURES

M

PRESSURE CURVES

PRESSURE CURVES/GAS DELIVERY

M

PRESSURE CURVES: The pressure curves indicate the output in kW according to the

backpressure in the combustion chamber, in mbars.

PRESSURE CURVES/GAS DELIVERY: These curves show the gas pressure, in milli-

bars, (at points Pi and Pt along the gas train) necessary to produce a given

delivery in m 3/h. The pressures have been measured with the burner working and with

a pressure of 0 mbar in the combustion

chamber. If the chamber is pressurized, the gas pressure necessary will be that given

in the diagram plus that in the combustion chamber.

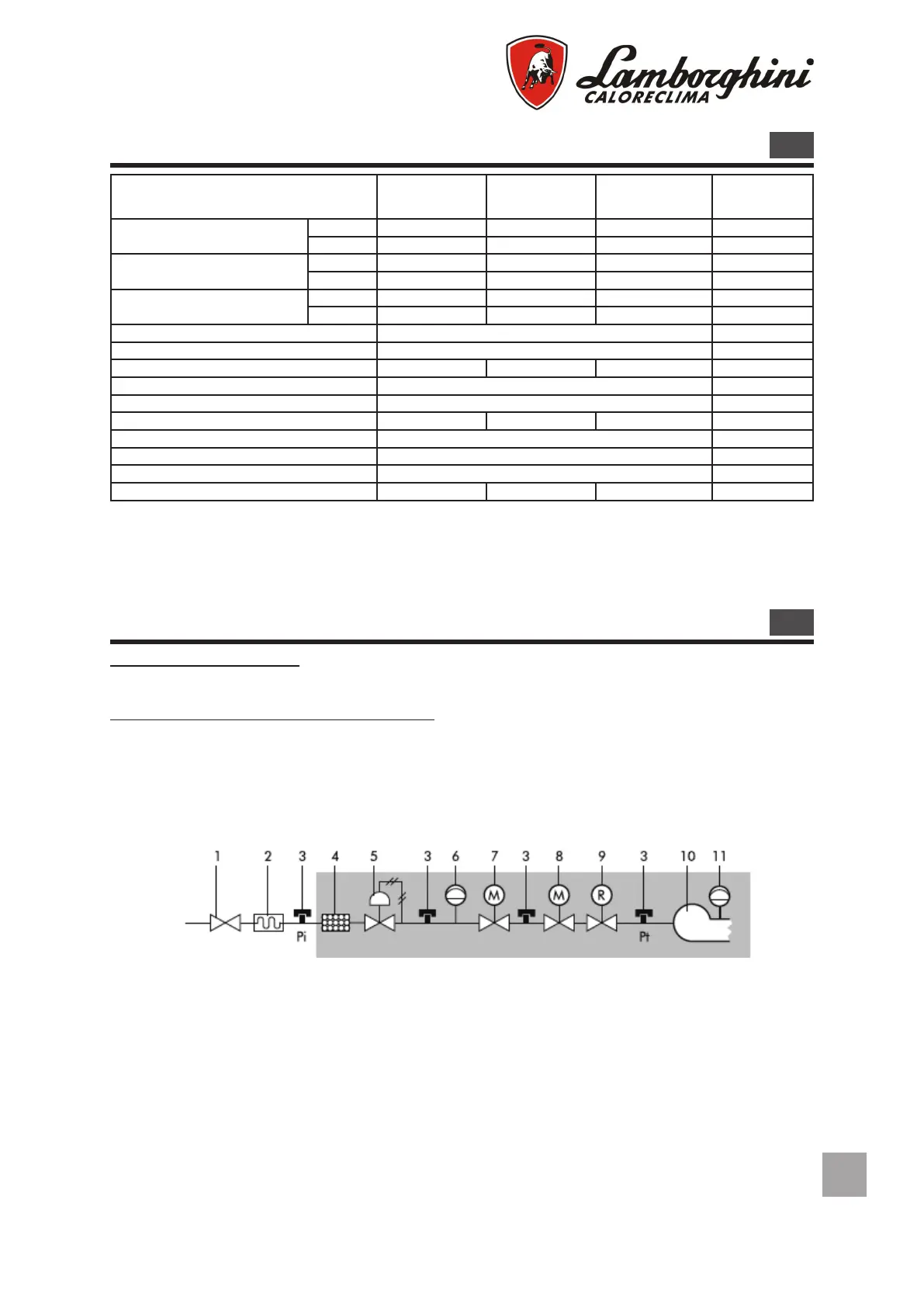

Legend

1 Interception cock - airtight at 1 bar and pressu-

re loss

0,5 mbar.

2 Vibration-damping joint

3 Gas pressure point for pressure reading

4 Gas lter

5 Gas pressure regulator

6 Minimum gas pressure control device (pressu-

re switch)

7 Class A solenoid safety valve. Closure time Tc

≤ 1”.

8 Class A solenoid safety valve. Closure time Tc ≤ 1”.

Ignition power between 10% and 40% of rated ther-

mal

power.

9 Gas delivery regulator, normally incorporated in ei-

ther solenoid valve 7 or 8.

10 Combustion head.

11 Minimum air pressure control device (pressure

switch)

BASIC GAS TRAIN

Model EM 3-E EM 6-E EM 9-E

Methane delivery

min 1,2 2,7 4,3 m

3

/h

max 3,8 6,7 9,0 m

3

/h

B/P delivery

min 0,4 1,0 1,5 m

3

/h

max 1,4 2,4 3,2 m

3

/ho

Thermal output

min 11,9 27,0 43,0 kW

max 37,7 66,6 89,5 kW

Motor 100 W

Trasformer 12/48 kV/mA

Max. absorbed power 220 215 230 W

Methane pres sure 20 mbar

B/P pressure 30 mbar

Weight 11,5 12,6 13,7 kg

Power supply 230V - 50/60Hz single-phase

Category II 2H 3P

Electric protection rating 20 IP

Noise level* 60 61 70 dB(A)

(*) Sound pressure measured in the manufacturer’s combustion laboratory, with burner operating on a test boiler and at maxi-

mum output.

Loading...

Loading...