16

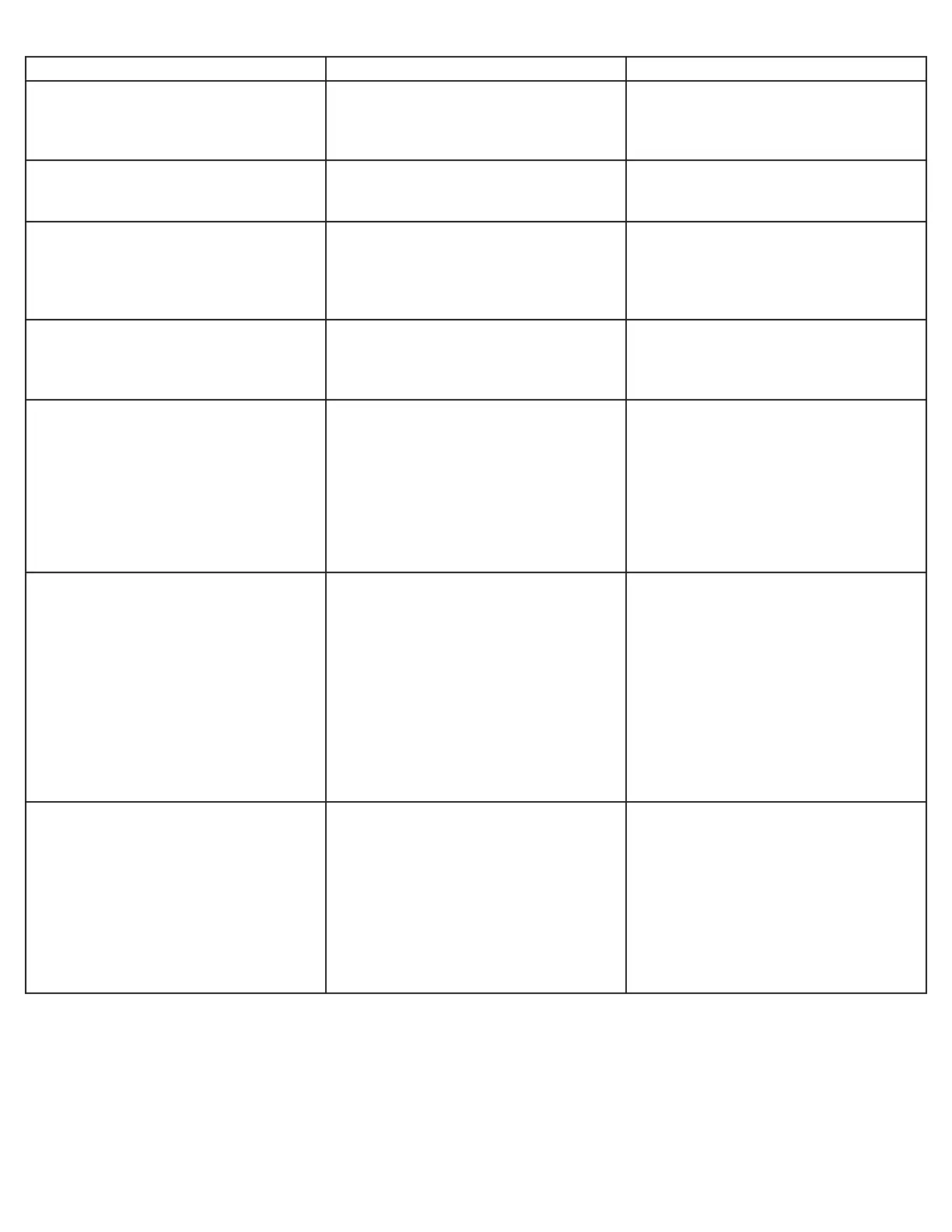

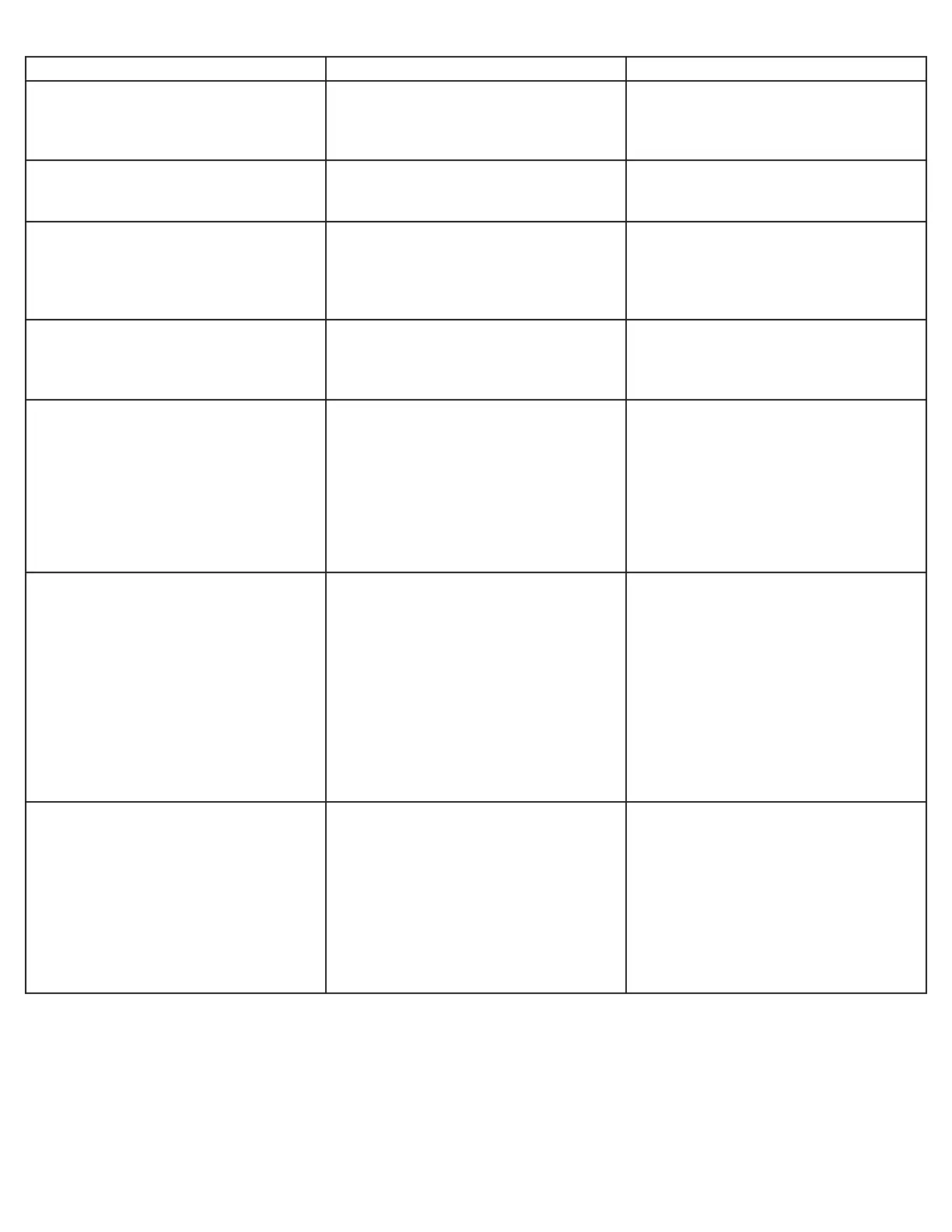

ISSUE CAUSE SOLUTION

3.7 Water in ice bin. A. Coldplate drain is obstructed. A. Remove splash plate and drip tray to

obtain access to drain tubes and clear

accordingly.

3.8 Water leakage around nozzle. A. Damaged or improperly installed o-ring

on nozzle.

A. If damaged, replace. If improperly

installed, adjust.

3.9 Miscellaneous leakage. A. Gap between parts.

B. Damaged or improperly installed

o-rings.

A. Tighten appropriate retaining screws.

B. Replace or adjust appropriate o-rings.

3.10 Noisy/cavitating carbonator pump. A. Insufcient incoming water

supply pressure.

A. Verify incoming supply water

pressure to carbonator pump is min. of

25 PSI, max. of 50 PSI.

3.11 Insufcient soda ow (carbonated

drinks).

A. Insufcient CO2 supply pressure.

B. Shutoff on mounting block is not fully

open.

C. Foreign debris in soda ow control.

A. Verify incoming CO2 pressure is

between 70-75 PSI.

B. Open shutoff fully.

C. Remove soda ow control from valve

and clean out any foreign material to

ensure smooth spool movement.

3.12 Insufcient water ow (plain water

drinks).

A. Insufcient incoming supply pressure.

B. Shutoff on mounting block not fully

open.

C. Foreign debris in water ow control.

D. Water ltration problem.

A. Verify incoming supply water pressure

to plain water inlet is a minimum of

75 PSI, max. of 125 PSI.

B. Open shutoff fully.

C. Remove water ow control from valve

and clean out any foreign material to

ensure smooth spool movement.

D. Service water system as required.

3.13 Erratic ratio. A. Incoming water and/or syrup supply

not at minimum owing pressure.

B. Foreign debris in water and/or syrup

ow control.

C. CO2 regulator malfunction.

A. Check pressure and adjust.

B. Remove ow control from suspected

valve and clean out any foreign

material to ensure smooth spool

movement.

C. Repair or replace CO2 regulator.

Loading...

Loading...