18

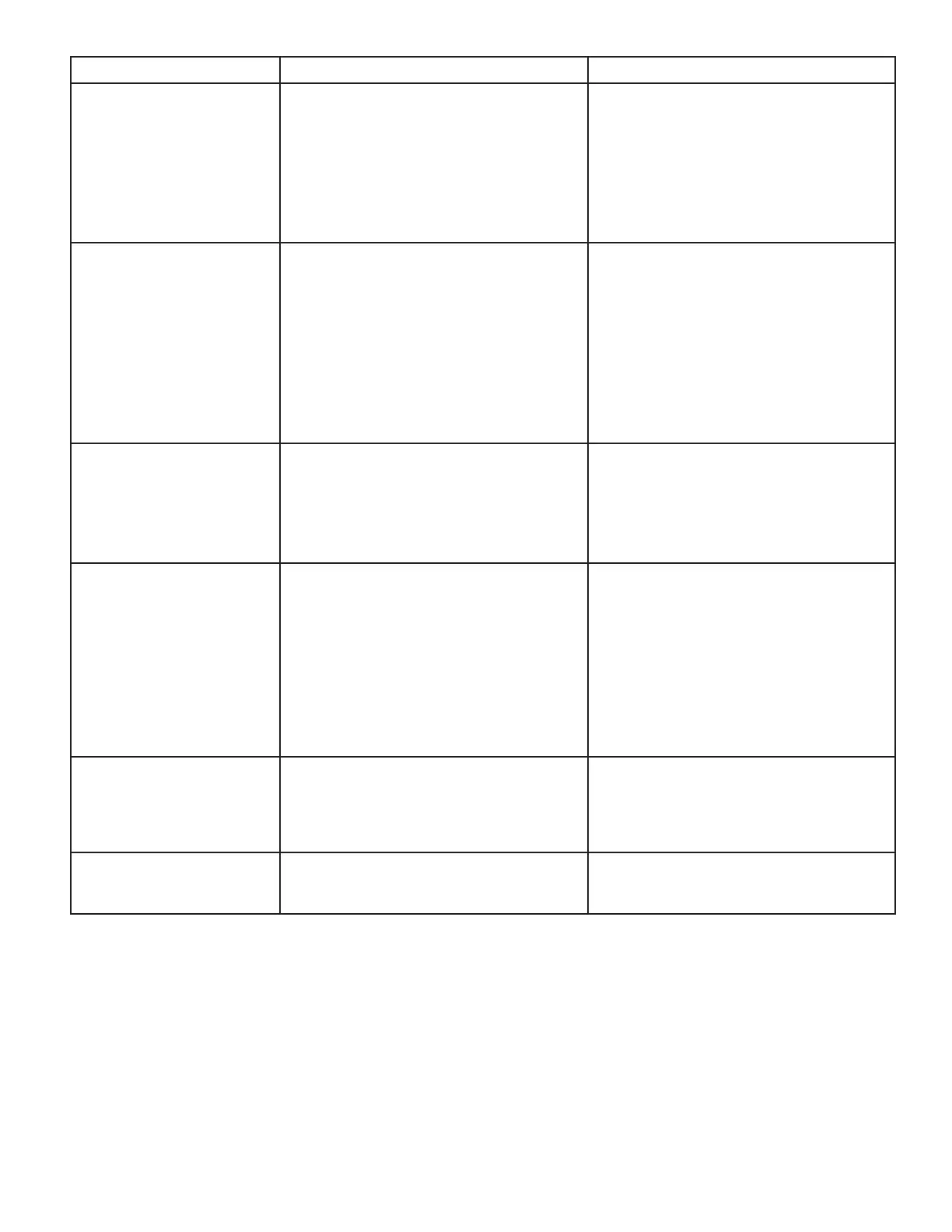

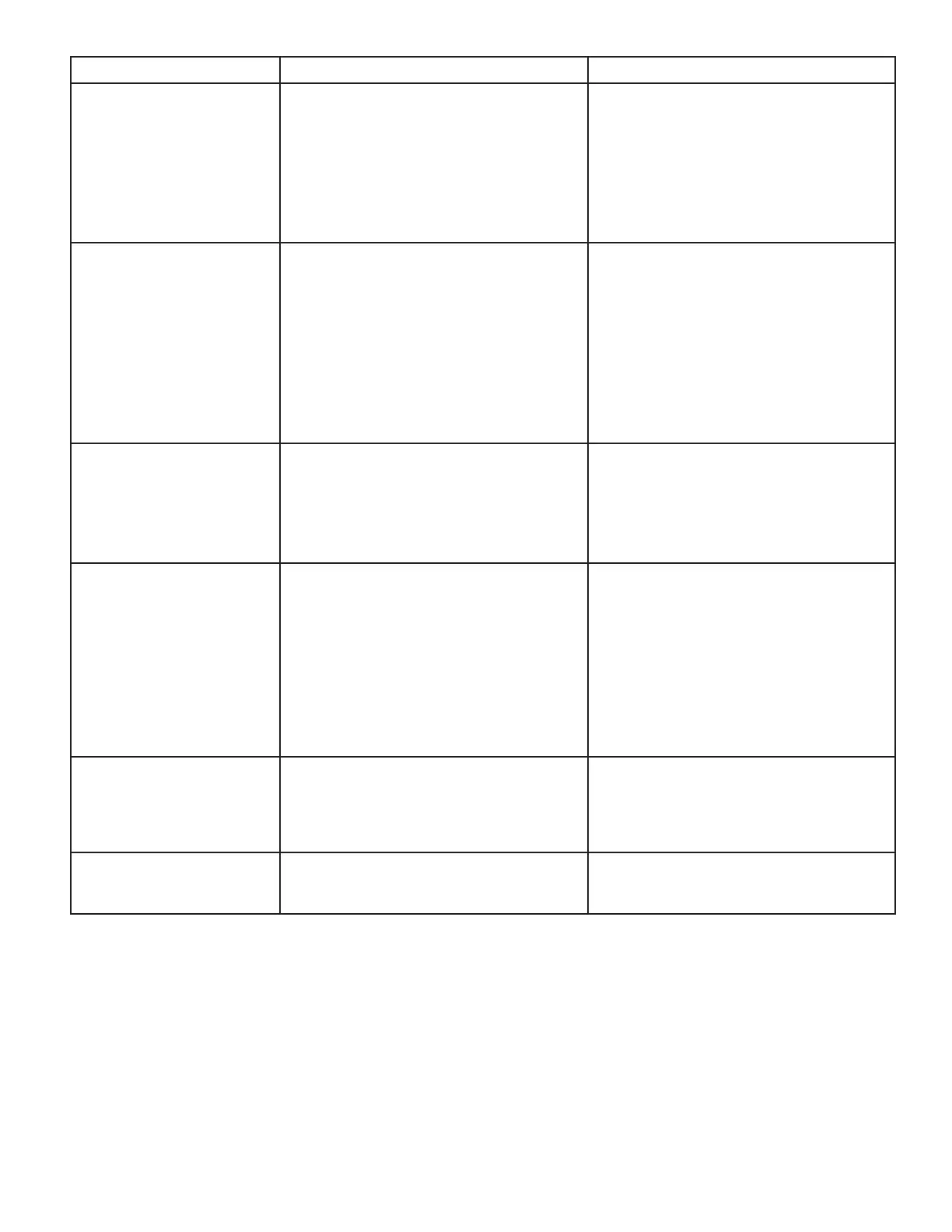

TROUBLE CAUSE REMEDY

Insucient soda ow

(carbonated drinks)

1. Insucient CO

2

supply pressure

2. Shuto on mounting block is not fully open

3. Foreign debris in soda ow control

4. Defective LFCV module

1. Verify incoming CO2 pressure is between

70-75 PSI (0.482 - 0.517 MPA)

2. Open shuto fully

3. Remove soda ow control from valve and

clean out any foreign material to ensure

smooth spool movement

4. Replace module

Insucient water ow (plain

water drinks)

1. Insucient incoming supply pressure

2. Shuto on mounting block not fully open

3. Foreign debris in water ow control

4. Water ltration problem

5. Defective LFCV module

1. Verify incoming supply water pressure to

plain water inlet is a min of 75 PSI (0.517

MPA), max of 125 PSI (0.862 MPA).

2. Open shuto fully

3. Remove water ow control from valve and

clean out any foreign material to ensure

smooth spool movement

4. Service water system as required

5. Replace module

Erratic ratio 1. Incoming water and/or syrup supply not at

min owing pressure

2. Foreign debris in water and/or syrup ow

control

3. CO

2

regulator malfunction

1. Check pressure and adjust

2. Remove ow control from suspected valve

and clean out any foreign material to

ensure smooth spool movement

3. Repair or replace CO

2

regulator

Insucient syrup ow 1. Insucient CO

2

pressure to BIB pumps

2. Shuto on mounting block not fully open

3. Foreign debris in syrup ow control

4. Defective BIB pump

1. Adjust CO

2

pressure to BIB pumps to

80 PSI (0.552 MPA) (min. 70 PSI (0.482

MPA)). Do not exceed manufacturer’s

recommendations

2. Open shuto fully

3. Remove syrup ow control from valve and

clean out any foreign material to ensure

smooth spool movement

4. Replace pump

Valve will not shut o 1. Debris in solenoid seat

2. Solenoid plunger sticking

1. Activate valve a few times to free debris.

Remove the solenoid coil and plunger.

Clean out any foreign material

2. Replace solenoid coil

Water continually leaking at

connections

1. Loose water connections

2. Flare seal washer leaks

1. Tighten water connections

2. Replace are seal washer

Loading...

Loading...