19

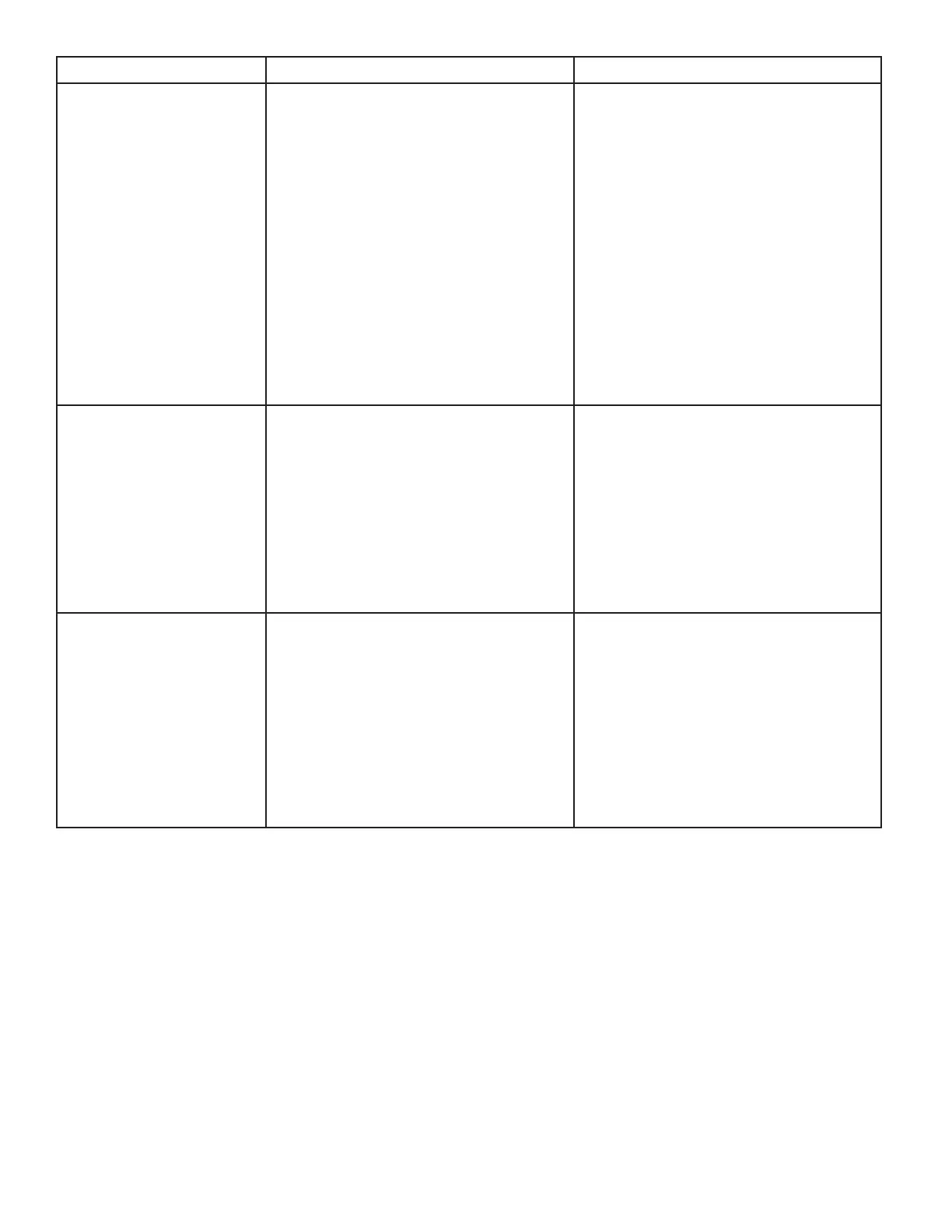

TROUBLE CAUSE REMEDY

Water only dispensed, no

syrup. Or syrup only dispensed,

no water

1. Syrup BIB empty

2. Water or syrup shuto on mounting block

not fully open

3. Improper or inadequate water or syrup

supply

4. CO2 pressure to syrup pump too low

5. Stalled or inoperative BIB pump

6. Kinked line

7. CO2 regulator malfunction

8. Defective LFCV module

1. Replace syrup BIB as required

2. Open shuto completely

3. Remove valve from mounting block &

o p e n s h u t o s s l i g h t l y . C h e c k w a t e r & s y r u p

supply. If no supply, check unit for other

problems. Ensure BIB connection is

engaged

4. Check the CO

2

pressure to the pump to

ensure it is between 70-80 PSI (0.482 -

0.552 MPA)

5. Check CO

2

pressure and/or replace pump

6. Remove kink or replace line

7. Repair or replace CO

2

regulator as

required

8. Replace module

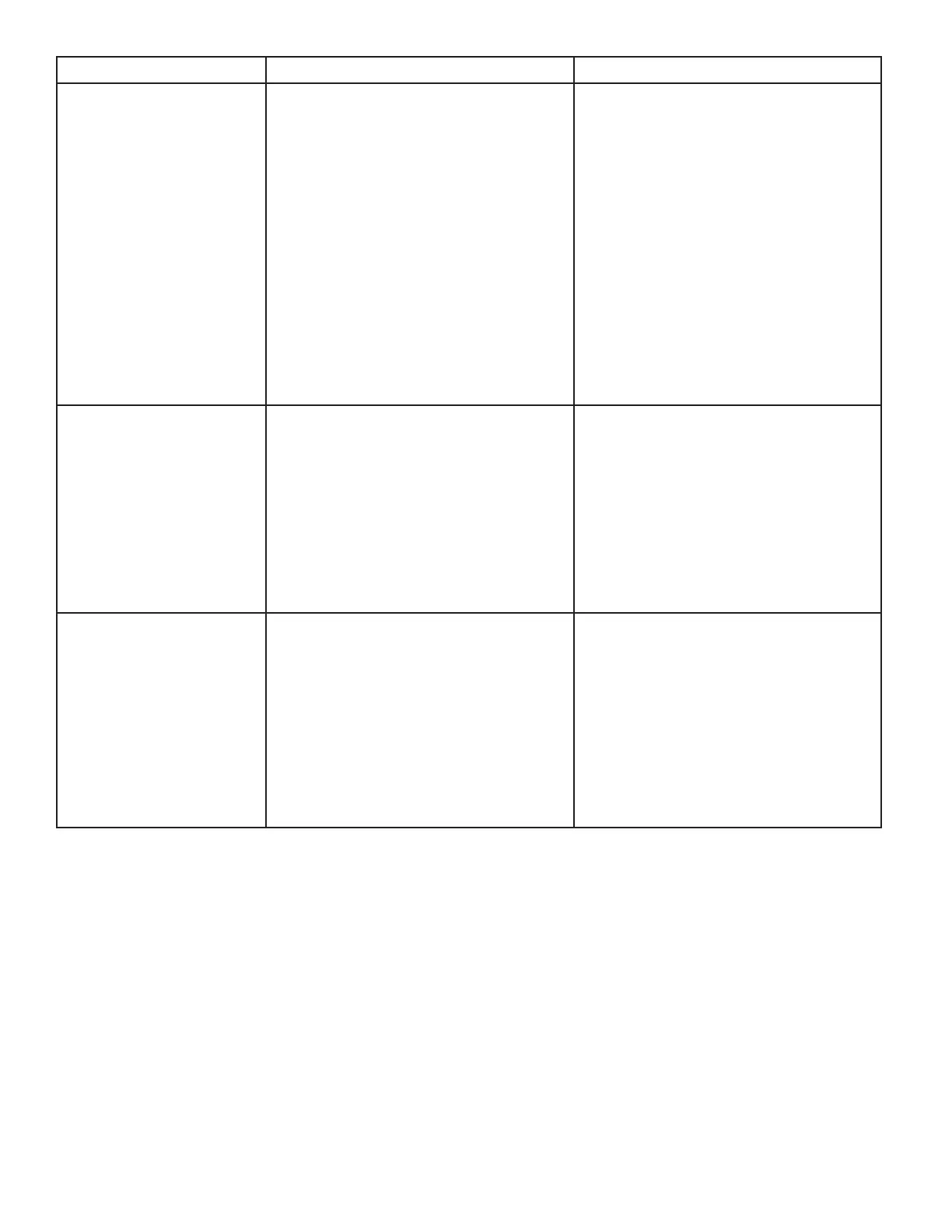

Syrup only dispensed. No

water, but CO

2

gas dispensed

with syrup

1. Improper water ow to dispenser

2. Carbonator pump motor has timed out

(display message on the LCD screen)

3. Liquid level probe not connected prop-

erly to PCB

4. Defective PCB assembly

5. Defective liquid level probe

6. Weak or defective carbonator pump

1. Check for water ow to dispenser

2. Reset by turning the unit OFF, then ON

by using the circuit breaker on the power

supply or momentarily unplugging unit

3. Check connections of liquid level probe to

PCB assembly

4. Replace PCB assembly

5. Replace liquid level probe

6. Replace pump

Excessive foaming 1. No ice in bin

2. Ice not touch cold plate

3. Incoming water or syrup temperature too

high

4. CO

2

pressure too high

5. Water ow rate too high

6. Nozzle and diuser not clean

7. Air in BIB lines

1. Fill bin with ice and allow cold plate to

re-stabilize

2. Increase auto agitation time

3. Correct prior to dispenser

4. Adjust CO

2

pressure downward, but not

less than 70 PSI (0.482 MPA)

5. Re-adjust and reset ratio

6. Remove and clean

7. Bleed air from BIB lines

Loading...

Loading...