Page 4PROTECTOR® IV Top of Rail Installation, Operation & Maintenance Manual

Digital Control Box

Ensure digital control box is switched OFF before working in tank.

Tools Required

The PROTECTOR IV unit comes equipped with an Allen wrench tool (for use on the pump mounting bolts). This

tool is required for installation and maintenance of the pump.

Along with the supplied tool, the PROTECTOR IV unit can be installed and maintained with a minimum number

of other tools. Ensure the following list of tools are available during the installation process (tools for the metric

equivalents are in brackets):

1. Pick and ballast fork

2. Large and medium size adjustable wrench

3. Medium pipe wrench

4. ½” drive reversible ratchet

5. 1” open-end wrench for sensor cable wall connector

6. 10 mm open-end wrench or socket for battery terminal

7. &YZ[\]&L^Q&++R&#.%T*)&.3&.<*/G*/;&53*/%4&).&+.2/)&#*/#.3&).&>3"%T*)

8. Slot and Phillips screwdrivers

9. Wire strippers and crimpers

10. Pliers or channel locks

11. For wiping bar and sensor bracket:

» 0 -250 ft.-lbs. (0-350 N-m) torque wrench

» ^G_]&LPO&++R&53*/%4&.3&#.%T*)

» Hammer (minimum weight 3 lb. (1 kg.))

BASIC SYSTEMS & CONFIGURATION

The following section is intended to provide a general overview of the operation of the PROTECTOR IV with a

brief description of key components.

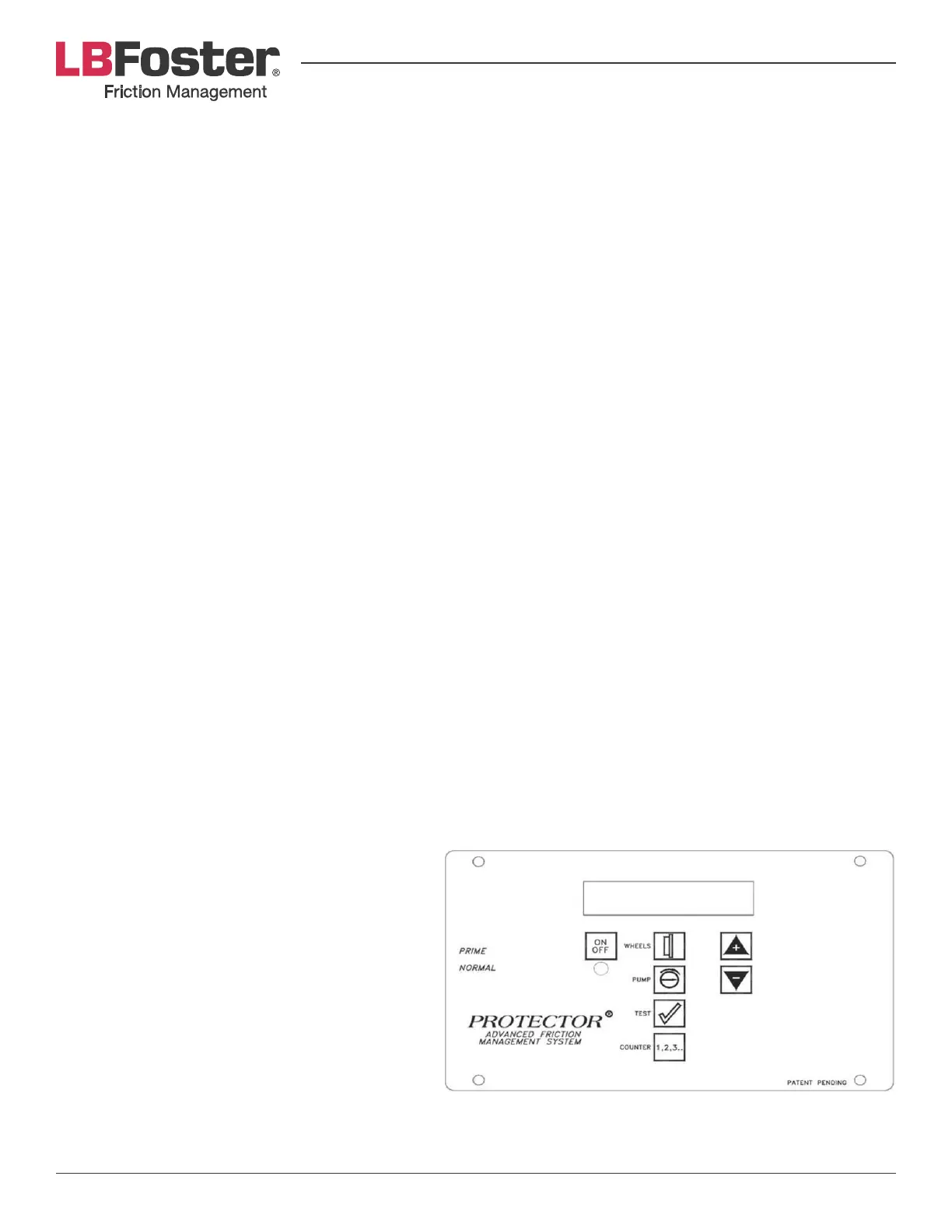

Digital Control Box

The Digital Control Box (DCB) is the heart of

PROTECTOR IV’s control system. It provides

excellent adjustability of the amount of grease

that is pumped from the tank to the bars. It

also provides integrity checks for verifying the

electronic controls and motor(s) are working

properly. The LCD screen at the top of the box

displays all of the information for the operator.

Pump

A double gear pump is coupled to the electric

motor. The pump/motor assembly distributes the

grease to the rails.

Loading...

Loading...