Adjusting the

Finger Assembly

SUPERJIG - CHAPTER 2

7

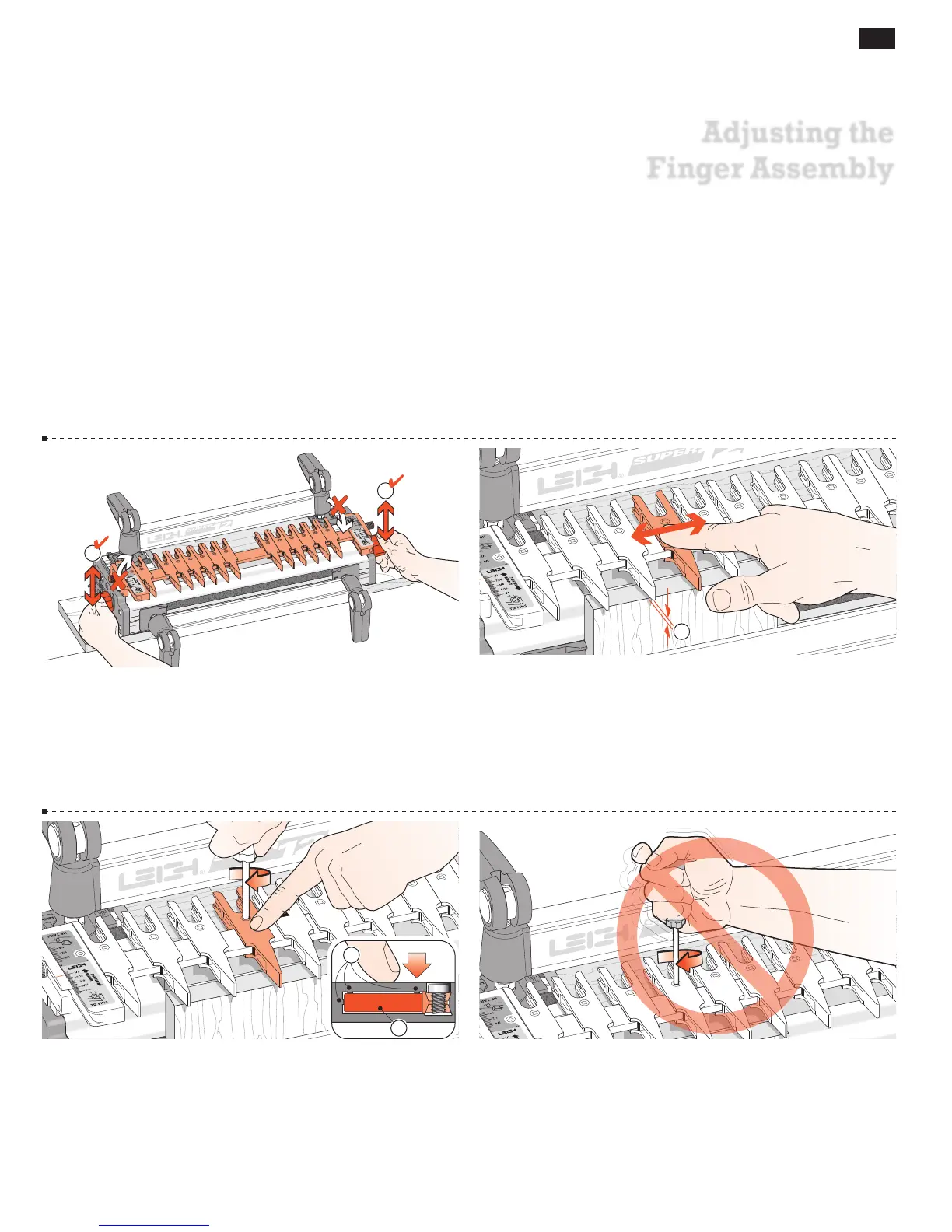

2-1 Practice with the finger assembly height adjustment. Loosen

the support bracket knobs and hold them firmly. Raise and lower

the assembly evenly, keeping it level

, and tighten the knobs to

lock it at various heights. Do not raise or lower only one end of

the finger assembly.

1

1

2-2 To practice adjusting the guidefingers, put a board in the front

clamp. Always raise the finger assembly slightly, approximately

1

⁄16"[2mm] above the spacer board and/or workpiece

. This is

essential to allow the guidefingers to move freely on the guidefinger

bar and ensures that the fingers will be level and flush when locked

up. Move the guidefingers by pushing on the middle to slide them

along the guidefinger bar.

1

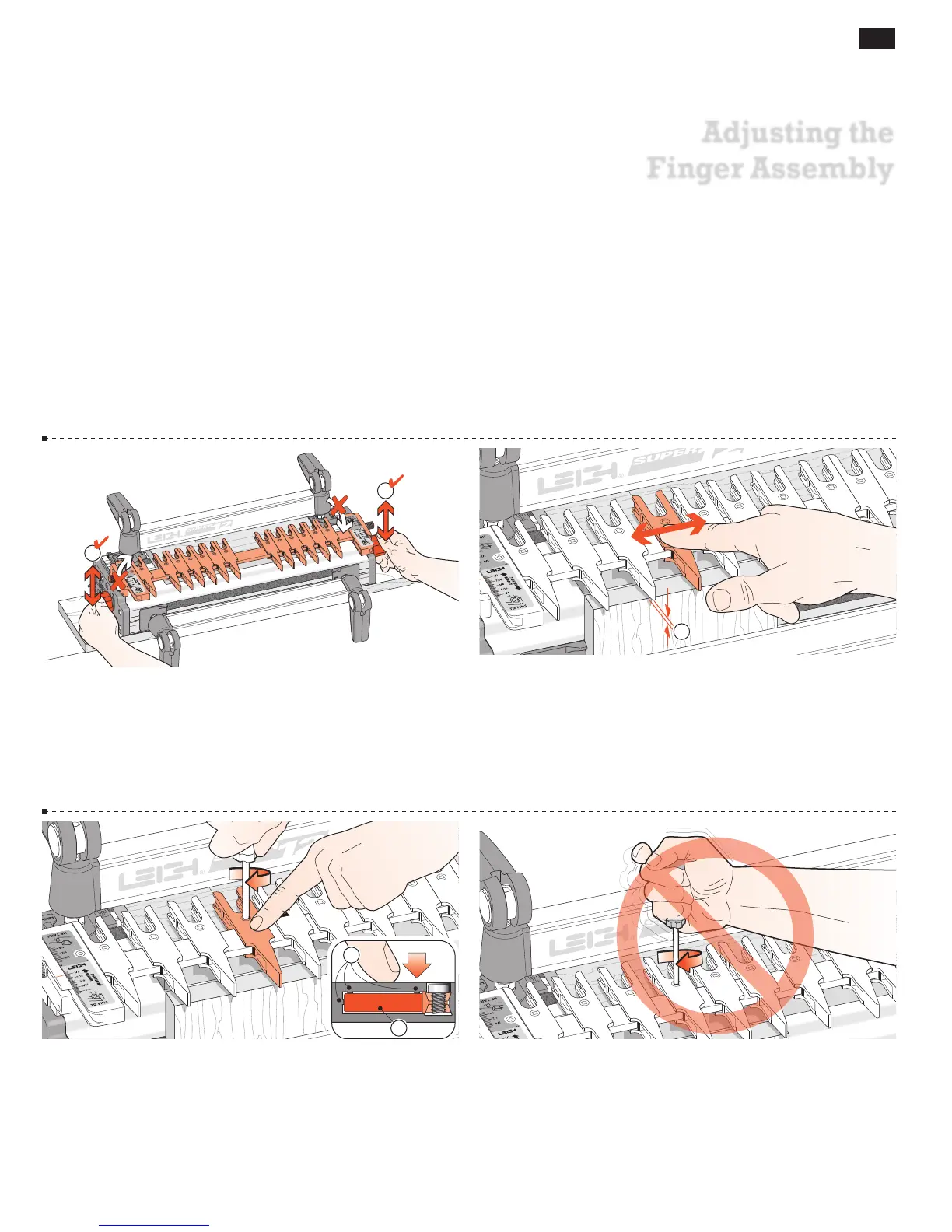

2-3 Loosen about half the guidefingers and practice unlock-

ing, moving, positioning and re-locking them. Always press on

the center of the guidefinger when tightening the screws. This

ensures that the small pads

on the inside of the finger contact

the face of the finger bar

and keeps all the fingers level.

1

2

2-4 Do not over-tighten the guidefinger lock screws. The Leigh

screwdriver provided will give ample torque for easy lock-up with-

out strain.

Hint: Fingertip tighten a loose screw until the slightest resistance is

felt. Do not tighten the screw more than half a turn (180˚) from the

first contact.

Loading...

Loading...