31

VARIABLY SPACED HALF-BLIND DOVETAIL PROCEDURES

Chapter 9Super Jig-12-18-24 User Guide

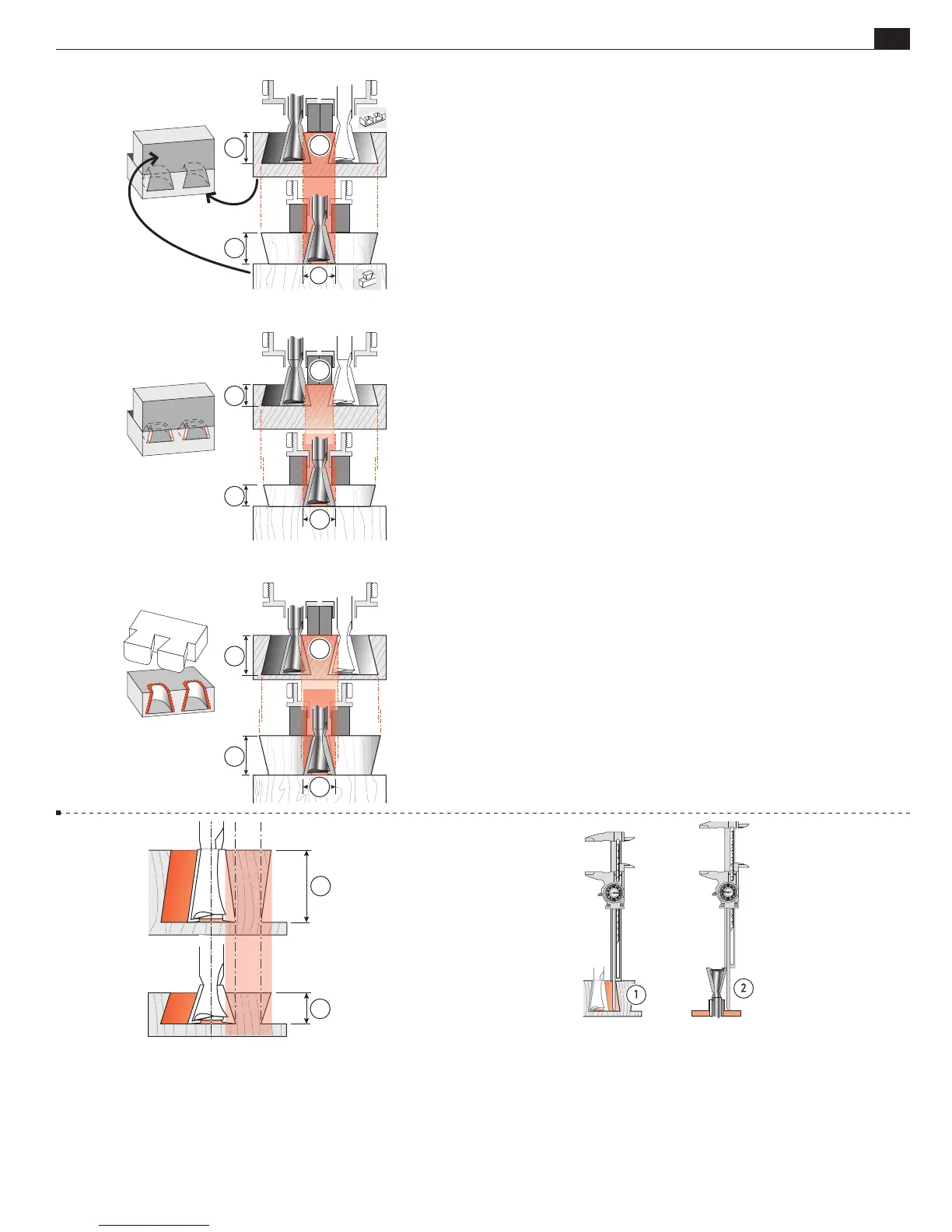

9-3 Joint Fit and Depth of Cut

Here’s why the depth of cut

changes the fit in half-blind dove-

tails. Increasing or decreasing the depth of cut does not affect the

pin socket width

, but does affect the width of the pin

that

goes into the socket

.

1

3

2

1

1

3

2

1

PIN

2

1

3

1

9-4 Note that decreasing the bit depth

makes the pin

narrower while the pin socket

stays the same width, producing

a loose fit.

Decreasing the bit depth (i.e. raise the bit into the router) pro-

duces a looser fit.

9-5 Increasing the bit depth

makes the pin

larger while

the pin socket

stays the same width, producing too tight a fit.

Increasing the bit depth (i.e. lower the bit) produces a tighter fit.

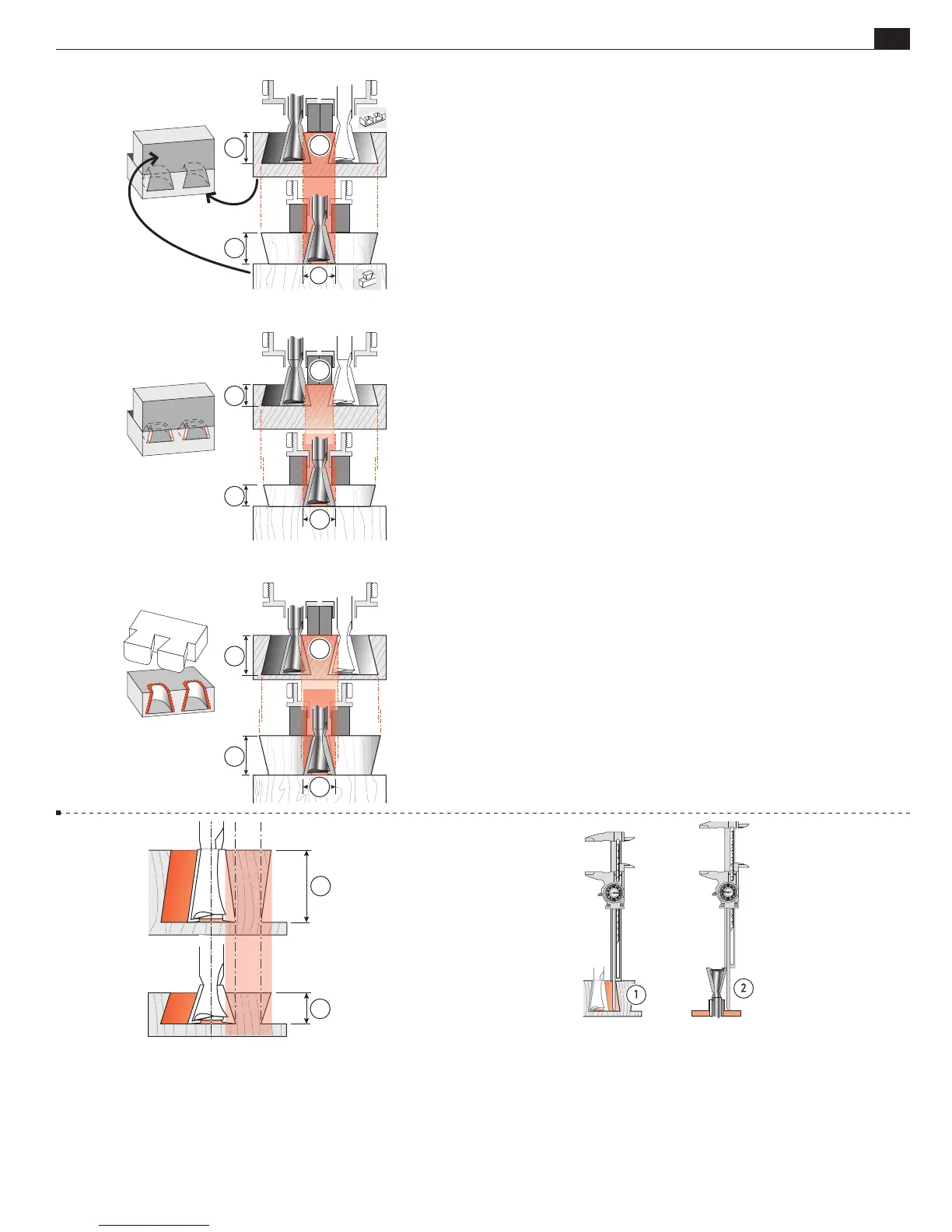

9-6 Bit Angle and Depth of Cut Half-blind pins and tails

are routed with the same dovetail bit, the same guidebush, and

the same depth of cut. A different depth of cut requires a differ-

ent angled bit. Leigh offers five different angled dovetail bits for

a range of cut depths. A lesser angle, say 8˚, for a deeper cut

; a

greater angle, say 18˚, for a shallower cut

.

1

2

18˚

8˚

9-7 Cumulative plus/minus tolerances in routers, bits and

guidebushes, make it impossible to state exact bit depth for first-

time precision fit. All dovetail jigs require trial and error tests to

attain fine fitting joints. The good news; we give a starting depth

for each bit. Test and measure the successful ‘Best fit’ depth of

cut

or bit projection

. Record for future first-time fits.

Loading...

Loading...