VARIABLY SPACED HALF-BLIND DOVETAIL PROCEDURES

32

Chapter 9 Super Jig-12-18-24 User Guide

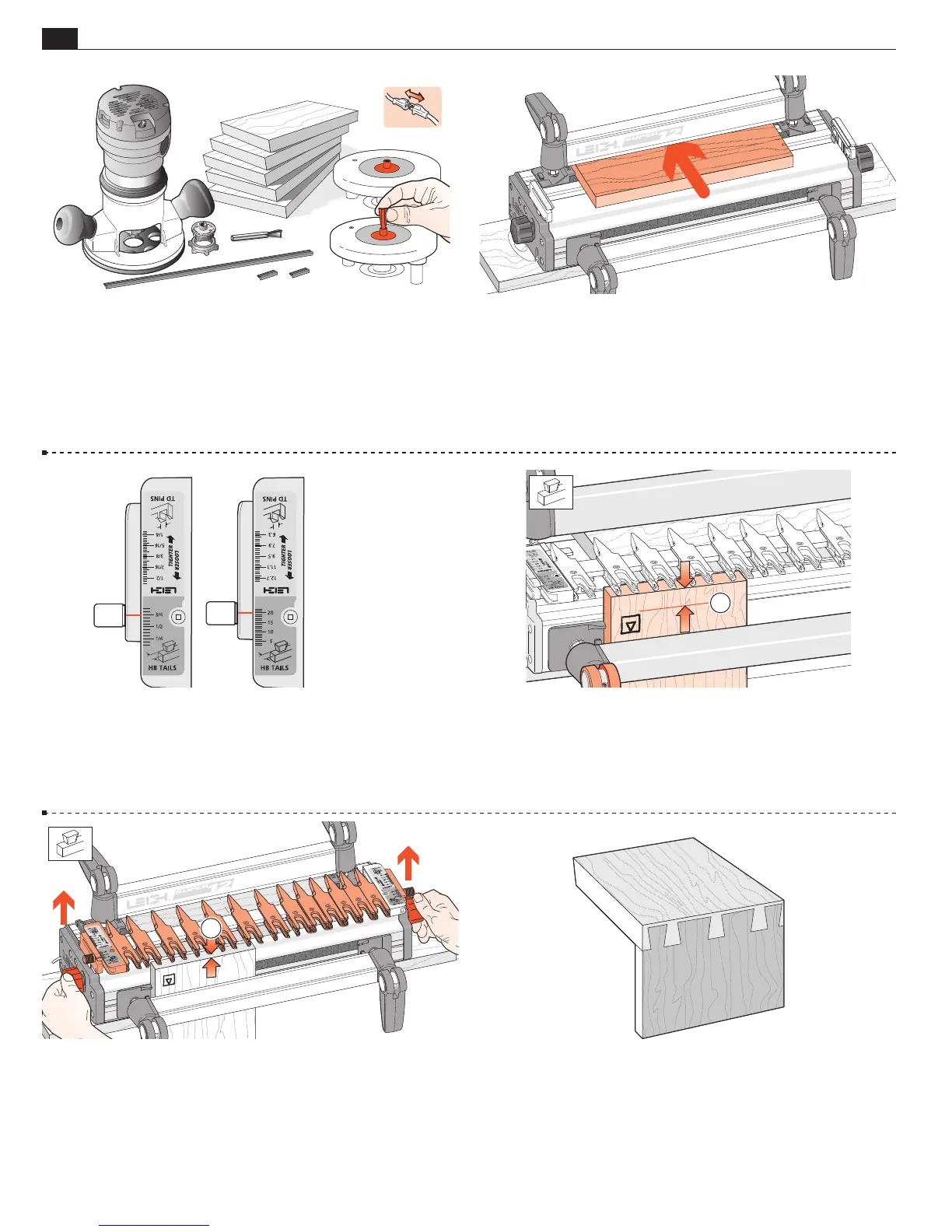

9-8 Routing a Test Joint Use the e7-Bush or a

7

⁄16"[11,1mm]

diameter bush (min. depth

1

⁄4" see page 67) and No.120-8

1

⁄2"[12,7mm] 14° dovetail bit. (80-series bits cut too deep for

3

⁄4"[20mm] boards, see HB bits, Appendix II). Select several pieces

of

3

⁄4"x5

1

⁄2"[20x140mm] x about 8"[200mm], and the plastic

bridge. Note: Half-blind pin boards must be minimum ½"[13mm]

thick to clamp. Thinner boards; see 9-21.

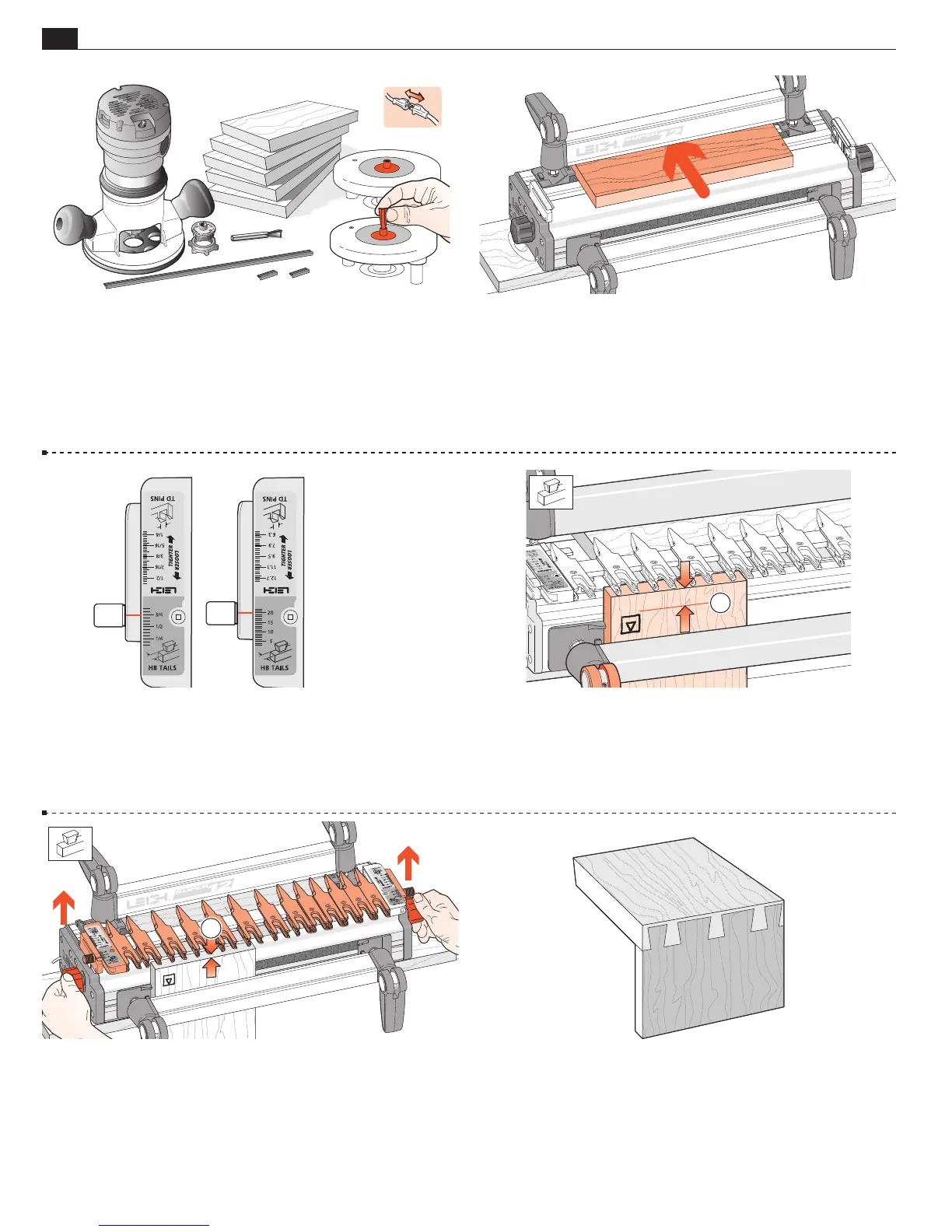

9-10 Mount the finger assembly on the support brackets in the

H

HB TAILS mode, flat on the spacer board, scales set on the

thickness of the tail board (

3

⁄4"[20mm] in this instance).

The

H

HB TAILS scale is always set at the tail board thickness.

Max tailboard thisckness is 1" however max scale setting is 3/4".

9-11 Measure and mark a line on the inside face of the tail board

to the bit’s depth of cut as in 9-2. Clamp this test tail board in

the left front clamp, against the side stop with the top edge flush

under the guidefingers, and the inside face

i

of the drawer side

away from the jig.

�

9-12 Unlock and raise the finger assembly support brackets

slightly so that the finger assembly is about

1

⁄16"[2mm]

above

the boards. This will allow easy movement of the guidefingers.

1

9-13 The following joint design is suggested for this trial. It has a

typical and traditional even layout of pins, with half-pins at each

edge. The Leigh jig, however, allows for an infinite variety of joint

designs, and boards of different thicknesses can be joined to each

other as shown in this illustration. Before attempting joints of

asymmetrical design, see chapter 12.

9-9 Clamp the spacer board in the rear clamp.

Loading...

Loading...