35

VARIABLY SPACED HALF-BLIND DOVETAIL PROCEDURES

Chapter 9Super Jig-12-18-24 User Guide

1

3

2

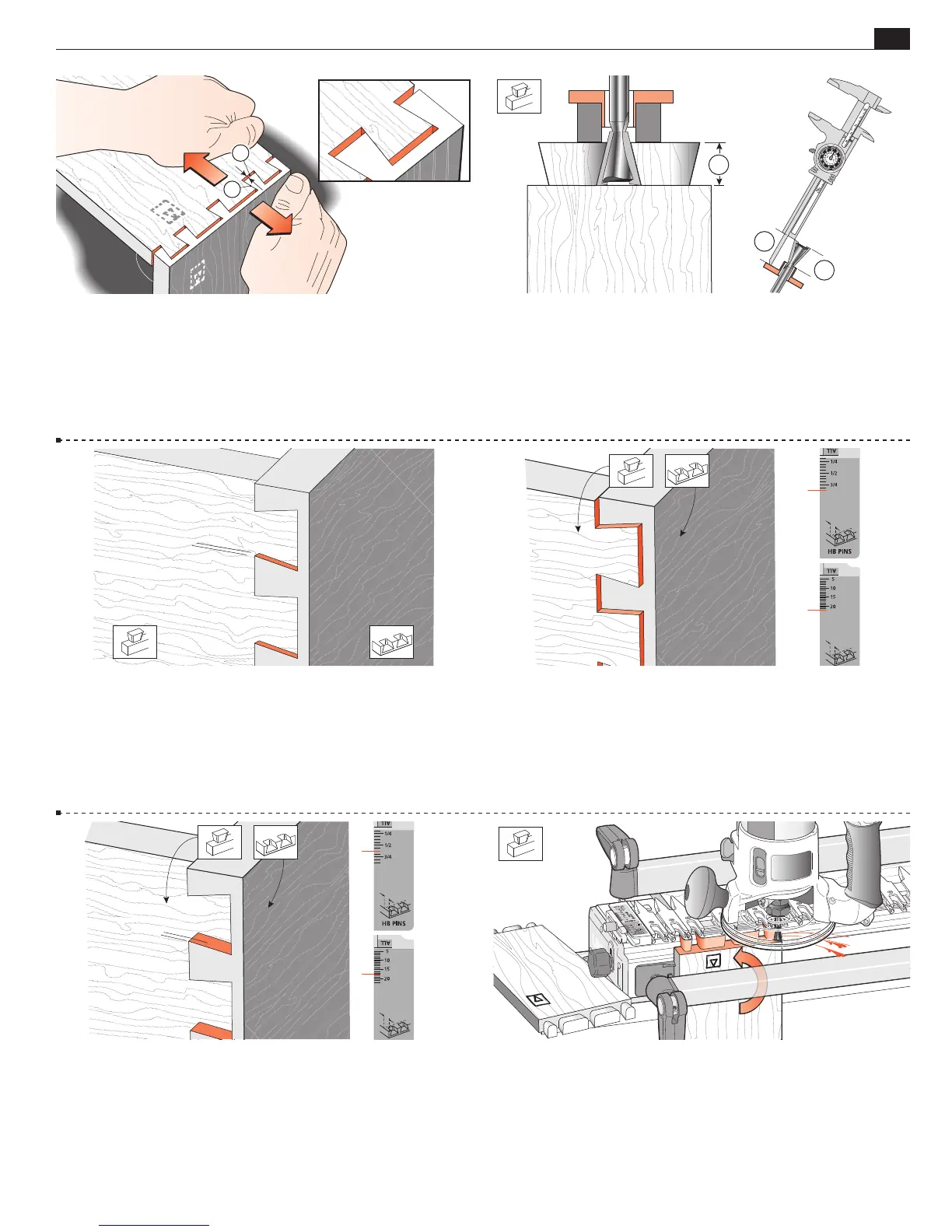

9-28 When you have the proper tightness of fit, check the flush-

ness. The tails should be under flush to the pins by no more than

1

⁄64"[0,3mm] to allow for cleanup (exaggerated here). Any concen-

tricity errors in the collet and guidebush on different routers will

affect this tolerance.

1/64[0,3mm]

9-29 If the tails stand out from the pins, set the

h

HB PINS

scale away from the operator by the amount required.

9-30 If the tails fit in too far past the pins ends, set the

h

HB

PINS scale toward the operator by the amount required. These

adjustments for “flushness” are made only in the

h

HB PINS

mode.

1/64"[0,3mm]

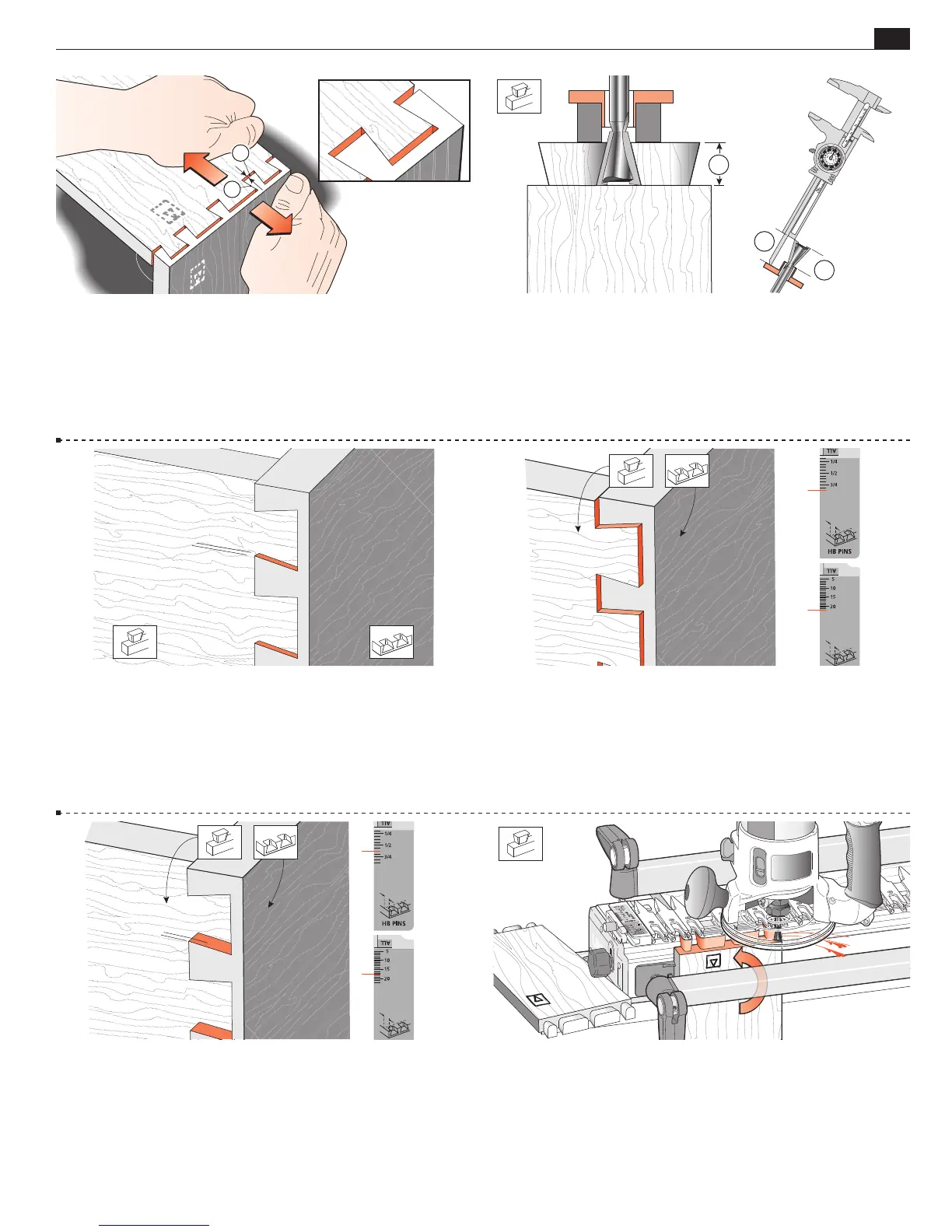

9-31 To make a box, rout all four ends of the tail boards, keeping

the inside face

i

of the tail boards away from the jig.

9-26 Remove the pin board and test for fit. If the joint is loose,

as shown here, you need to increase the bit cutting depth by the

same amount as the gap at the bottom of the pins

(when the

pins are pulled against the socket sides

). If the joint is too tight,

decrease the bit cutting depth slightly. Test again. Boards cannot be

routed twice with a dovetail bit, Use two fresh board ends for each test.

90

o

1

2

9-27 Keep the test tail board that fits well, and mark it with the

number of the bit you used to rout it. For quick set-up next time,

clamp this tail board in the jig as a depth-of-cut gauge

to show

how far to lower the bit. Better yet, measure the bit projection

from the end of the guidebush

or guidebush flange

and

record this for fast set-ups in future.

Loading...

Loading...