53

SLIDING DOVETAILS

Chapter 13Super Jig-12-18-24 User Guide

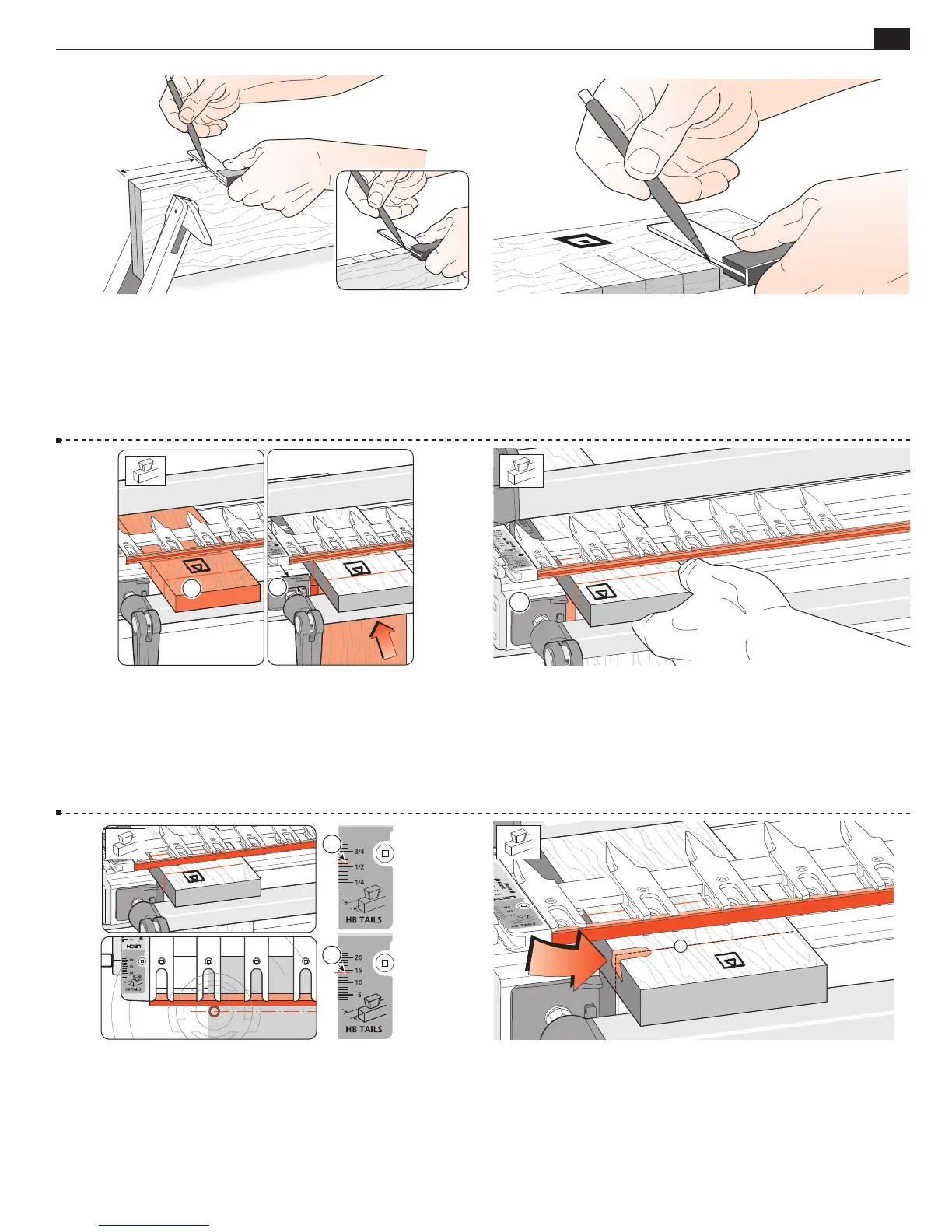

13-7 Marking Out: Do not mark the slot positions on the board

faces, Mark the edges of both slot boards together for perfectly level

shelves. Stay at least 7"[180mm] in from the ends for clamping

on this test project. 13-25 describes how to rout close to both ends.

Mark the narrow test slot board in the same way at several closely

spaced random spots. This board is used only for setup.

13-8 On the test slot board only, square the marks across the

face.

13-9 Mount the test slot board in the rear clamp, markings up

.

Mount a

3

⁄4"[20mm] thick

square-ended board vertically in

the front clamp against the side stop, with the top edge butting

the underside of the test board (yes, the 3⁄4"[20mm] thickness is

important).

2

1

13-10 Position and clamp the test board so that one of the edge

marks is in line with the outside edge of the vertical board

.

�

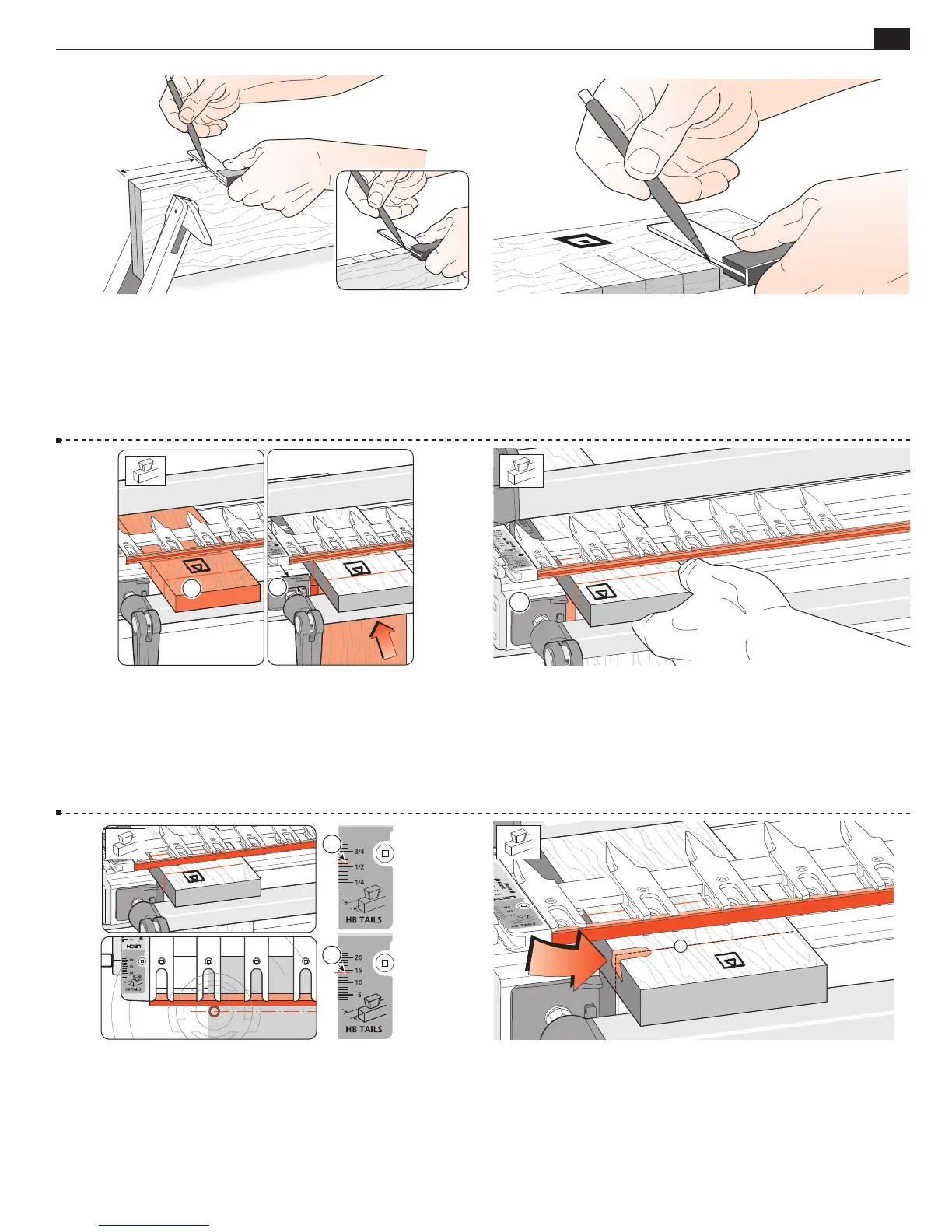

13-11 With the finger assembly (including the cross cut fence)

on the support brackets in the

H

HB TAILS mode, set the scale

to

9

⁄16"[14mm]

. The routed slot will be close to centred on the

slot line. Make sure the finger assembly is level and sitting flush on

top of the board.

�

�

13-12 Adjust the bit so the cut depth is about

5

⁄16"[8mm].

Rout from left to right maintaining light inward pressure of the

guidebush on the fence. Rout in only about 1"[25mm] and back

out again.

Do not lift the router.

Loading...

Loading...