HINTS AND TIPS

64

Chapter 15 Super Jig-12-18-24 User Guide

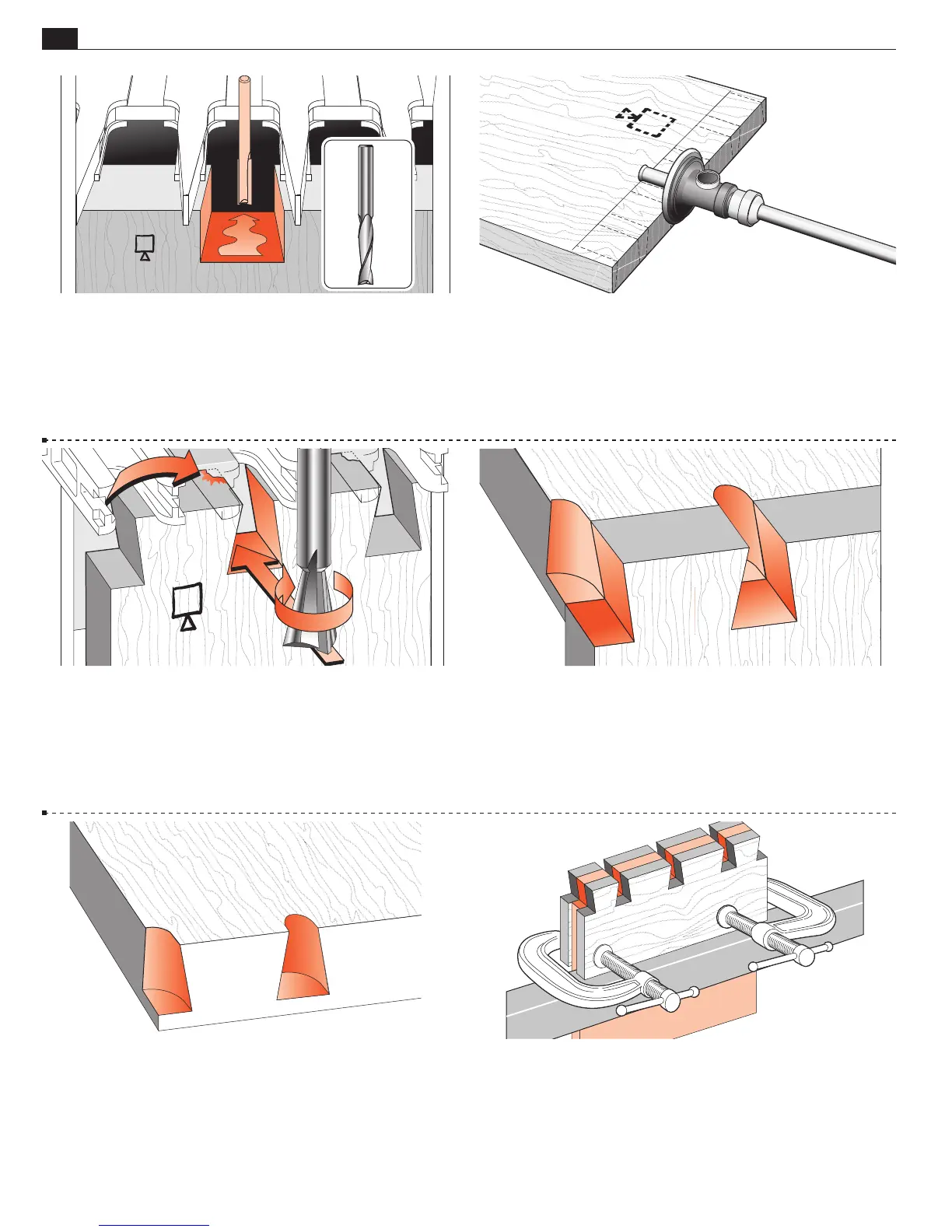

15-5 Rout away the rest of the waste. Note: Spiral up-cut straight

bits (inset) generally rout more smoothly than the two-flute

carbide-tipped bits. If you want to try them, you should be aware

that while the high-speed steel bits take a better edge, they are

much less durable than the more costly solid carbide type (Leigh

bits 170 HSS or 170C solid carbide).

15-6 Preventing TD Pins Tearout To help prevent tearout

at the back bottom part of a straight cut, scribe a line with your

marking gauge across the back of the pin board at exactly the

depth of cut.

15-7 Dovetail Tails Tearout With the dovetail bit, most

tearout occurs at the top left exit of the cut.

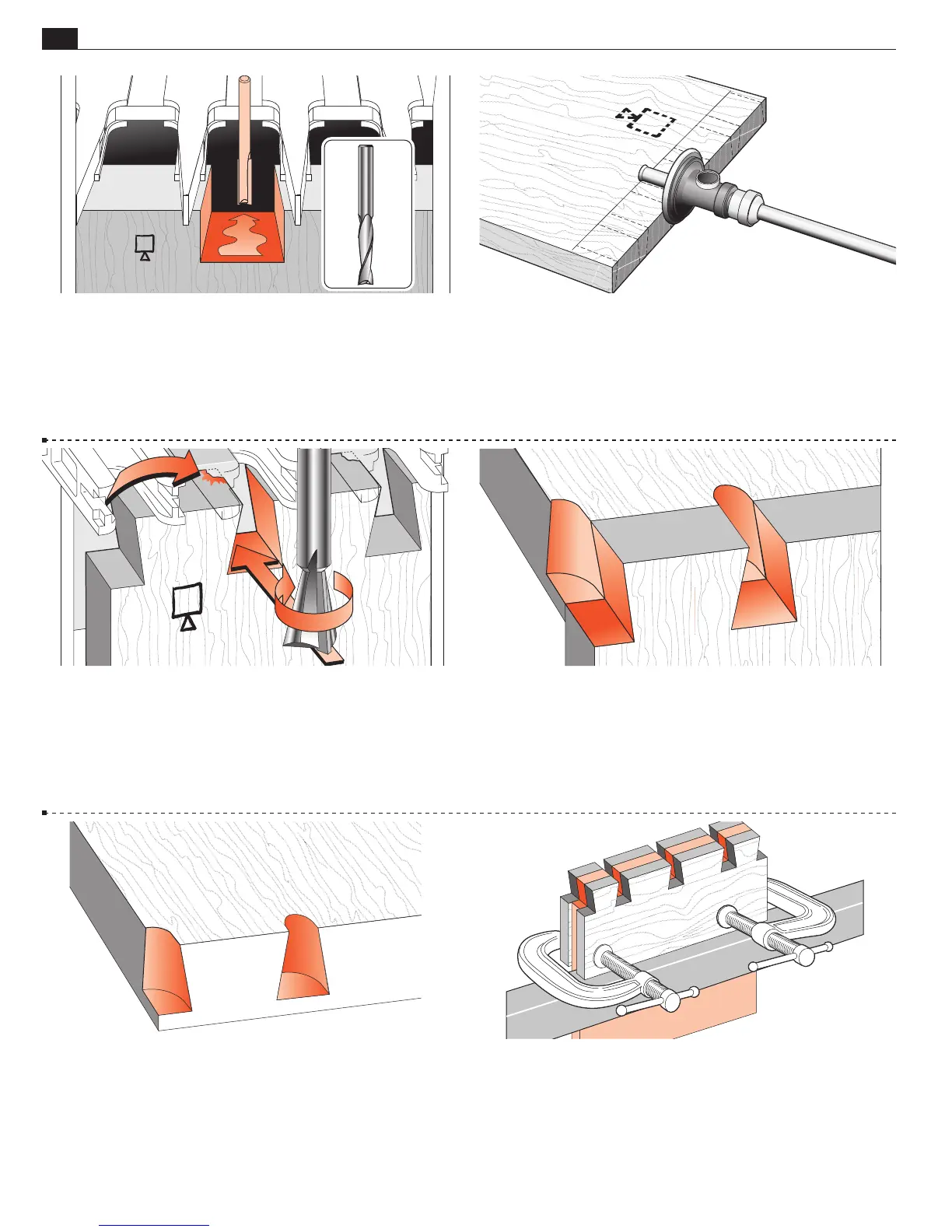

15-8 To help prevent this, back up the cut with the end-grain of

a horizontal board pushed against the back of the workpiece and

held in the rear clamp. This board replaces the spacer board.

15-9 This same scrap piece can remain in place for successive

cuts.

15-10 For vulnerable or that last piece of exotic wood, clamp

horizontal scrap pieces to the front and back of the work piece.

Make sure clamps are below the bit depth.

PLYWOOD is not suitable for routing; the laminates are very

prone to tearout. Either of these two procedures (15-10 or 15-11)

are essential for plywood but provide no guarantee of success.

Loading...

Loading...