Page 4

3 − Defrost System

12HPB units built prior to April 2002

The 12HPB defrost system includes two components: a

defrost thermostat, and a defrost control.

a − Defrost Thermostat

The defrost thermostat is mounted on the liquid line be-

tween the check/expansion valve and the distributor. When

defrost thermostat senses 35_F (2_C) or cooler, its contacts

close and send a signal to the defrost control board to start the

defrost timing. It also terminates defrost when the liquid line

warms up to 70_F (21_C).

b − Defrost Control

The defrost control board in the 12HPB series units has the

combined functions of a time/temperature defrost control, de-

frost relay, time delay, diagnostic LEDs and field connection

terminal strip.

The control provides automatic switching from normal heating

operation to defrost mode and back. During compressor cycle

(room thermostat demand cycle), if the O" input is not on and

the defrost thermostat is closed, the control accumulates com-

pressor run times at 30, 60, or 90 minute field adjustable inter-

vals. When the accumulated compressor run time ends, the

defrost relays are energized and defrost begins.

Defrost Control Timing Pins

Each timing pin selection provides a different accumulated

compressor run period during one thermostat run cycle.

The defrost interval can be adjusted to 30, 60 or 90 minutes.

See figure 4. The defrost period is a maximum of 14 minutes

and cannot be adjusted. If no timing is selected, the control de-

faults to 90 minutes.

A TEST option is provided for troubleshooting. When the

jumper is placed across the TEST pins, the timing of all

functions is reduced by a factor of 128. For example, a 30

minute interval during TEST is 14 seconds and the 14 min-

ute defrost is reduced to 6.5 seconds.

The TEST mode may be started at anytime. If the jumper is in

the TEST position at power−up or for longer than five minutes,

the control will ignore the TEST selection and will default to a

90 minute interval.

Time−Delay

12HPB model units built prior to August 1996 will fea-

ture a time off delay. The timed−off delay is five minutes

long. Without the time delay it would be possible to

short cycle the compressor. A scroll compressor, when

short cycled, can run backward if head pressure is still

high. It does not harm a scroll compressor to run back-

ward, but it could cause a nuisance tripout of safety lim-

its (internal overload). For this reason, if a TOC delay

should fail, it must be replaced. Do not bypass the con-

trol. Later model compressors have an arrest feature

which eliminates the need for the TOC. This feature is

internally built and mechanically prevents the compres-

sor from turning backwards.

Pressure Switch Safety Circuit

The defrost control incorporates a pressure switch safety

circuit that allows the application of up to two optional pres-

sure switches; high pressure and/or loss of charge. See

figure 4. During a demand cycle, the defrost control will

lock out the unit on the third instance the unit goes off on

any pressure switch wired to this circuit. The diagnostic LEDs

will display a pattern for a lockout pressure switch on the third

open pressure switch occurrence. See table 2. The unit will re-

main locked out until 24 volt power is broken to terminal R" on

the defrost board and then remade.

Remove factory−installed jumper before connecting op-

tional pressure switches to control board. When two pres-

sure switches are used, wire each switch to one set of ter-

minals PS1 and PS2 on the defrost control board. See fig-

ure 4. When only one pressure switch is used, wire the

switch to the two outside terminals of the pressure switch

connections.

NOTE: If not using a pressure switch, the factory−installed

jumper wire must be connected, or unit will not operate.

Ambient Thermistor & Service LightConnection

12HPB model units built prior to August 1996 will have a de-

frost control board which provides terminal connections for a

monitoring kit (part number 76F53) which includes an ambient

thermistor and a service light. The monitor kit provides a ser-

vice light thermostat which activates the room thermostat ser-

vice light during periods of inefficient operation. The thermistor

compensates for changes in ambient temperatures which

might cause excessive thermostat droop. Later 12HPB model

units do not have the terminal connections; however the mon-

itoring kit can still be used. See Installation Instructions for

proper wiring.

Diagnostic LEDs

The defrost board uses two LEDs for diagnostics. The

LEDs flash a specific sequence according to the condi-

tion.

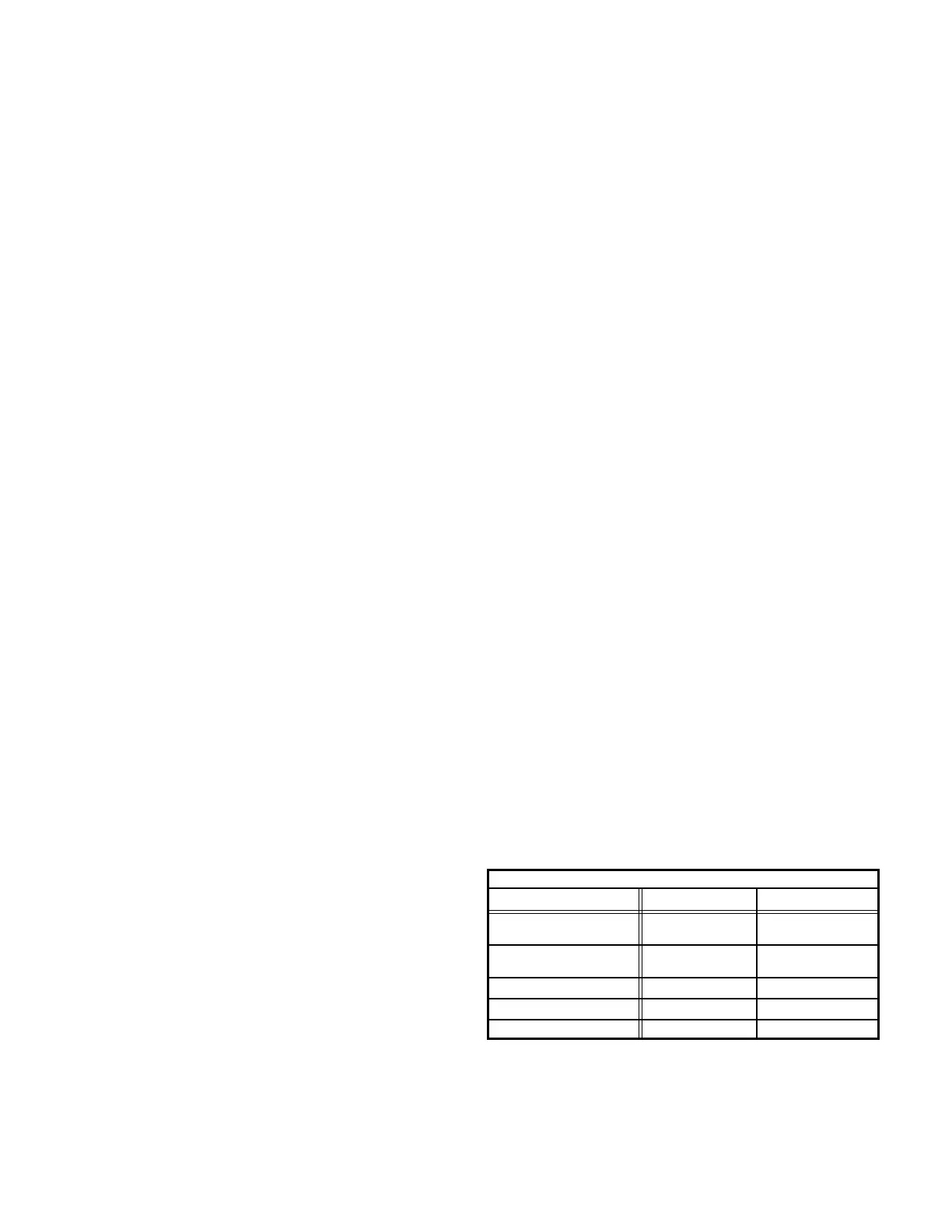

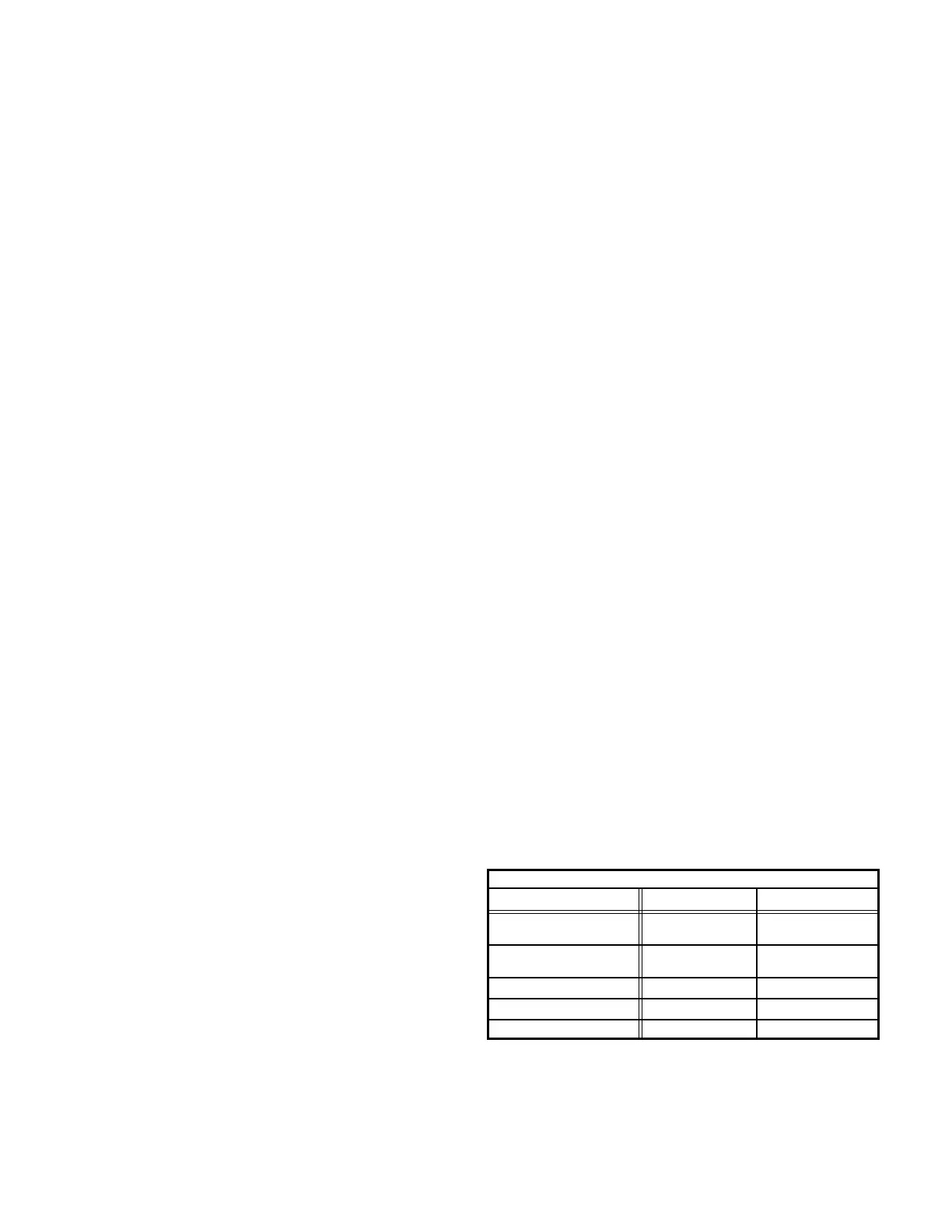

TABLE 2

DEFROST CONTROL BOARD DIAGNOSTIC LED

MODE LED 1 LED 2

Normal Operation/

Power to board

Flash together with

LED 2

Flash together with

LED 1

Time Delay

To Protect Compressor

Alternating Flashes

with LED 2

Alternating Flashes

with LED 1

Pressure Switch Open Off On

Pressure Switch Lockout On Off

Board Malfunction On On

Loading...

Loading...