Page 8

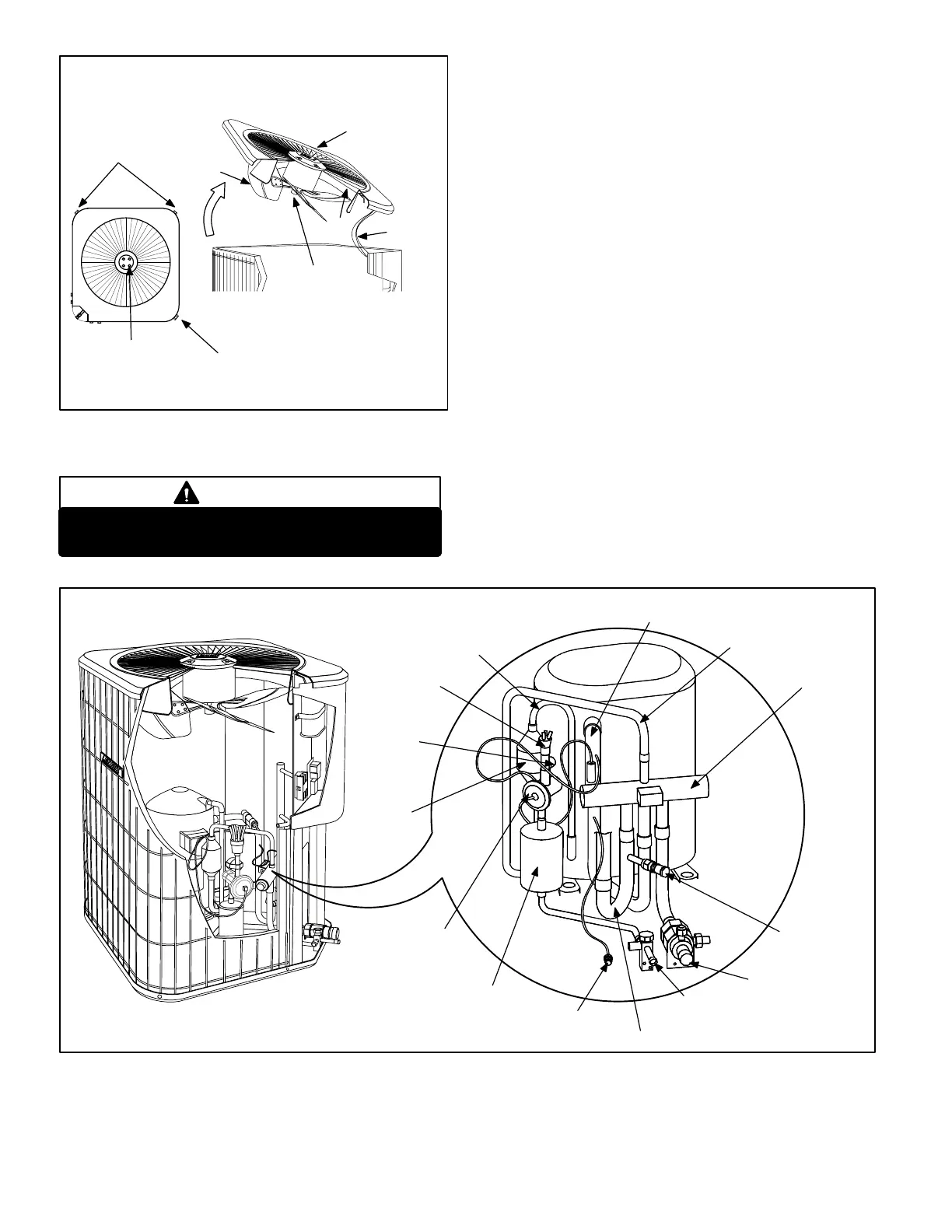

FAN

CONDENSER FAN MOTOR

AND COMPRESSOR ACCESS

Remove (7) screws

REMOVE (7) SCREWS

SECURING FAN GUARD.

REMOVE FAN GUARD/FAN

ASSEMBLY.

FAN GUARD

WIRING

FIGURE 10

Remove (4) nuts

ALIGN FAN HUB

FLUSH WITH

MOTOR SHAFT

Make sure all power is disconnected before

beginning electrical service procedures.

DANGER

C − Outdoor Fan Motor

All units use single−phase PSC fan motors which require a run

capacitor. In all units, the condenser fan is controlled by

the compressor contactor.

ELECTRICAL DATA tables in this manual show specifi-

cations for condenser fans used in 12HPBs.

Access to the condenser fan motor on all units is gained

by removing the seven screws securing the fan assem-

bly. See figure 10. The condenser fan motor is removed

from the fan guard by removing the four nuts found on

the top panel. If condenser fan motor must be replaced,

align fan hub flush with motor shaft. Drip loops should

be used in wiring when servicing motor.

D − Reversing Valve L1 and Solenoid

A refrigerant reversing valve with electromechanical so-

lenoid is used to reverse refrigerant flow during unit op-

eration. The reversing valve requires no maintenance. It

is not repairable. If the reversing valve has failed, it must

be replaced.

If replacement is necessary, access reversing valve by re-

moving the outdoor fan motor. Refer to figure 10.

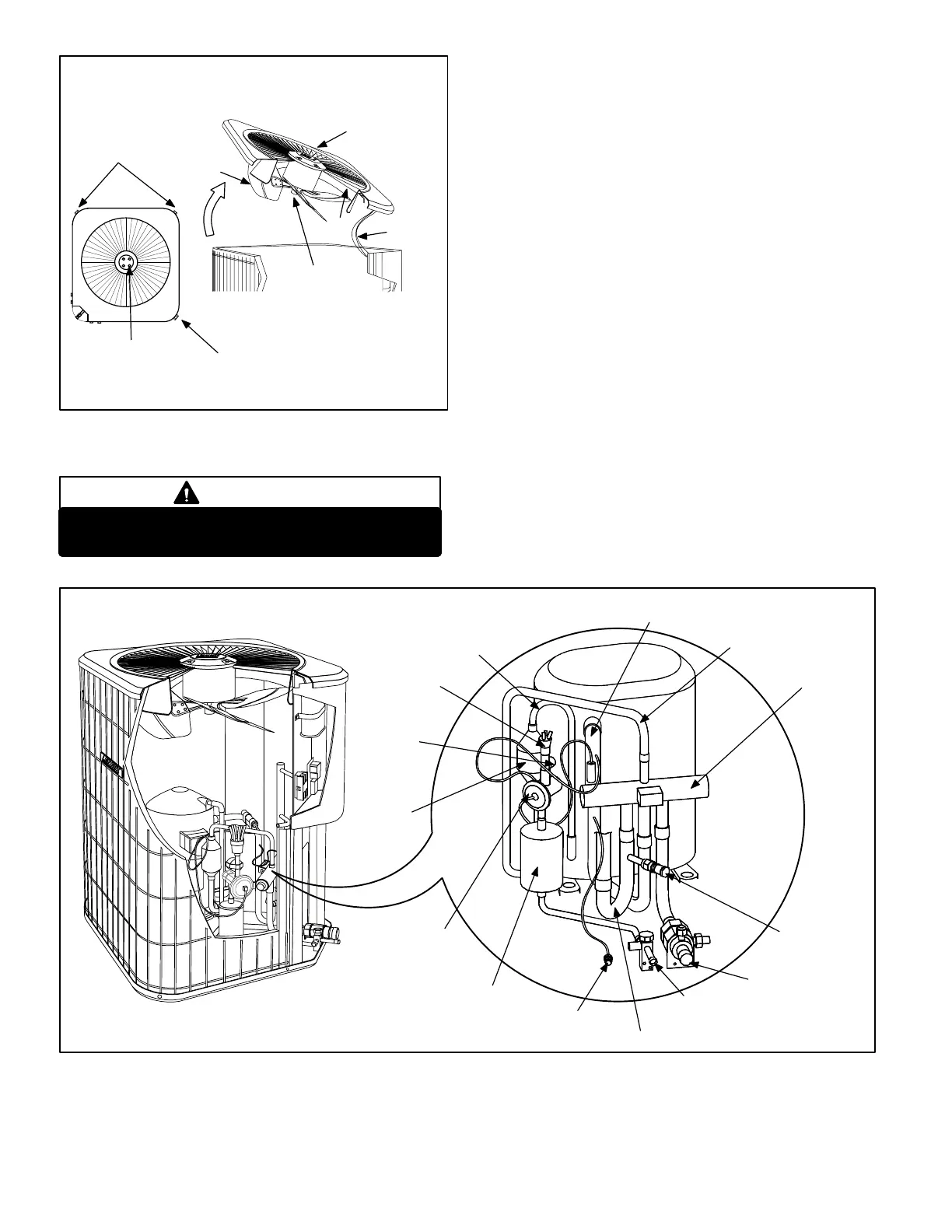

II − REFRIGERANT SYSTEM

See figure 11 for unit refrigerant components. Refer to figure

12 and 13 for refrigerant flow in the heating and cooling

modes. The reversing valve is energized during cooling

demand and during defrost.

VAPOR LINE

SERVICE

VALVE

MUFFLER

DISTRIBUTOR

FILTER/DRIER

(BI−FLOW)

REVERSING

VALVE

EXPANSION VALVE

FIGURE 11

12HPB REFRIGERATION COMPONENTS

LIQUID LINE

SERVICE VALVE

VAPOR LINE

PRESSURE TAP

FITTING

DEFROST

THERMOSTAT

PROCESS

COUPLING

SUCTION LINE

DISCHARGE

LINE

SUCTION LINE

CHECK AND

Loading...

Loading...