Page 3

STEP 2 – REFRIGERANT PIPING

IMPORTANT

If this unit is being matched with an approved line set

or indoor unit coil that was previously charged with

mineral oil, or if it is being matched with a coil which

was manufactured before January of 1999, the coil and

line set must be ushed prior to installation. Take care to

empty all existing traps. Polyol ester (POE) oils are used

in Lennox units charged with HFC-410A refrigerant.

Residual mineral oil can act as an insulator, preventing

proper heat transfer. It can also clog the expansion

device and reduce system performance and capacity.

Failure to properly ush the system per this instruction

and the detailed Installation and Service Procedures

manual will void the warranty.

Flush the existing line set per the following instructions.

For more information, refer to the Installation and Service

Procedures manual available on LennoxPros.com. CAU-

TION - DO NOT attempt to ush and re-use existing line

sets or indoor coil when the system contains contaminants

(i.e., compressor burn out).

If a new line set is being installed, size the piping per table 1.

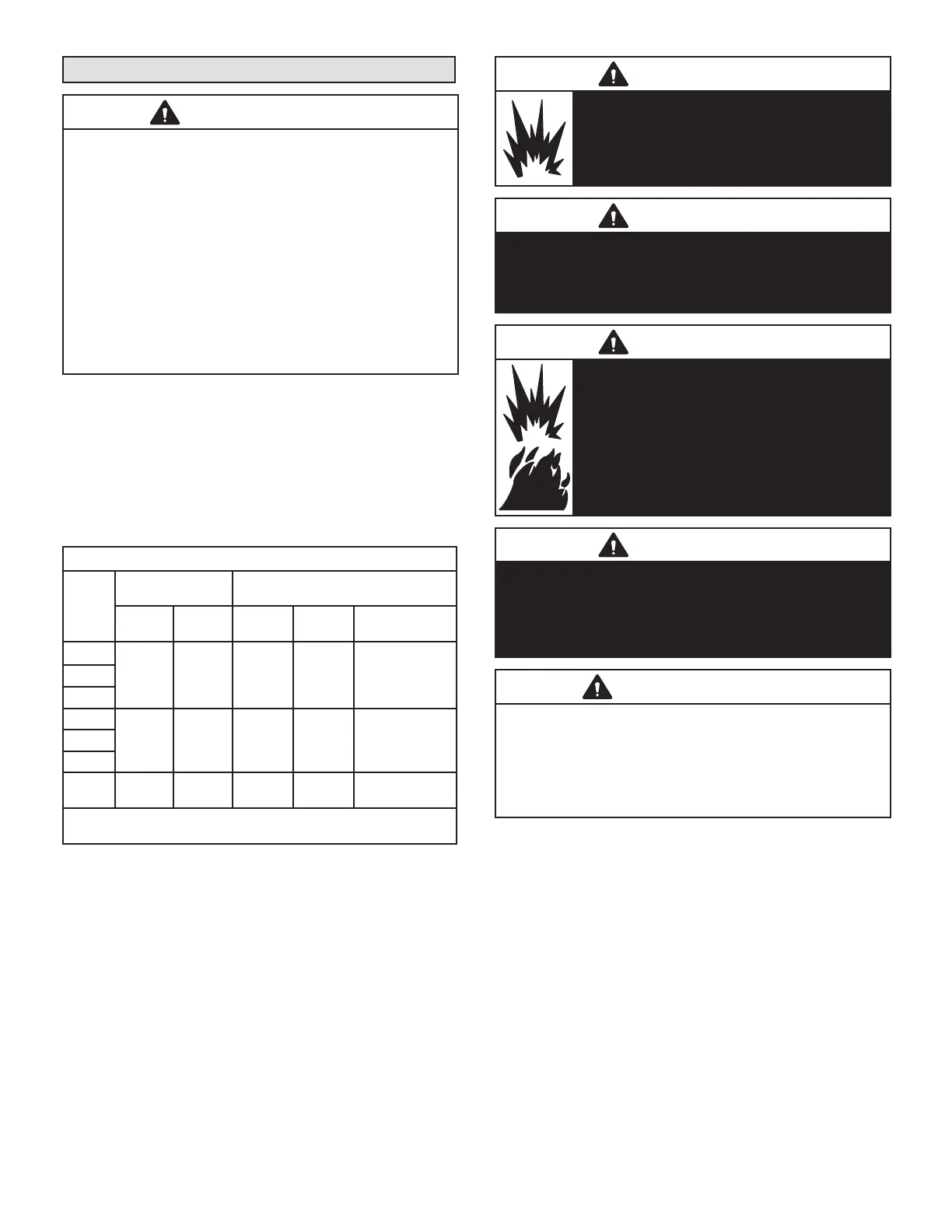

TABLE 1

REFRIGERANT LINE SET – INCHES (MM)

Model

Valve Field

Connections

Recommended Line Set

Liquid

Line

Vapor

Line

Liquid

Line

Vapor

Line

L15 Line Sets

-018

3/8 in.

(10 mm)

3/4 in.

(19 mm)

3/8 in.

(10 mm)

3/4 in.

(19 mm)

L15-41

15 ft. - 50 ft.

(4.6 m - 15 m)

-024

-030

-036

3/8 in.

(10 mm)

7/8 in.

(22 mm)

3/8 in.

(10 mm)

7/8 in.

(22 mm)

L15-65

15 ft. - 50 ft.

(4.6 m - 15 m)

-042

-048

-060

3/8 in.

(10 mm)

1-1/8 in.

(28 mm)

3/8 in.

(10 mm)

1-1/8 in.

(28 mm)

Field Fabricated

NOTE - Some applications may require a eld-provided 7/8" to

1-1/8" adapter.

NOTE - When installing refrigerant lines longer than 50

feet, refer to the Refrigerant Piping Design and Fabrica-

tion Guidelines manual available on LennoxPros.com

(Corp. 9351-L9), or contact the Technical Support Depart-

ment Product Application group for assistance.

NOTE - For new or replacement line set installation, refer

to Service and Application Note - Corp. 9112-L4 (C-91-4).

WARNING

When using a high pressure gas such as

nitrogen to pressurize a refrigeration or air

conditioning system, use a regulator that can

control the pressure down to 1 or 2 psig (6.9

to 13.8 kPa).

WARNING

Refrigerant can be harmful if it is inhaled. Refrigerant

must be used and recovered responsibly.

Failure to follow this warning may result in personal

injury or death.

WARNING

Fire, Explosion and Personal Safety hazard.

Failure to follow this warning could result in

damage, personal injury or death.

Never use oxygen to pressurize or purge

refrigeration lines. Oxygen, when exposed

to a spark or open ame, can cause re and/

or an explosion, that could result in property

damage, personal injury or death.

WARNING

Polyol ester (POE) oils used with HFC-410A refrigerant

absorb moisture very quickly. It is very important that the

refrigerant system be kept closed as much as possible.

DO NOT remove line set caps or service valve stub caps

until you are ready to make connections.

IMPORTANT

Some scroll compressors have an internal vacuum

protector that will unload scrolls when suction pressure

goes below 20 psig. A hissing sound will be heard when

the compressor is running unloaded. Protector will reset

when low pressure in system is raised above 40 psig.

DO NOT REPLACE COMPRESSOR.

Loading...

Loading...