Page 19

A11

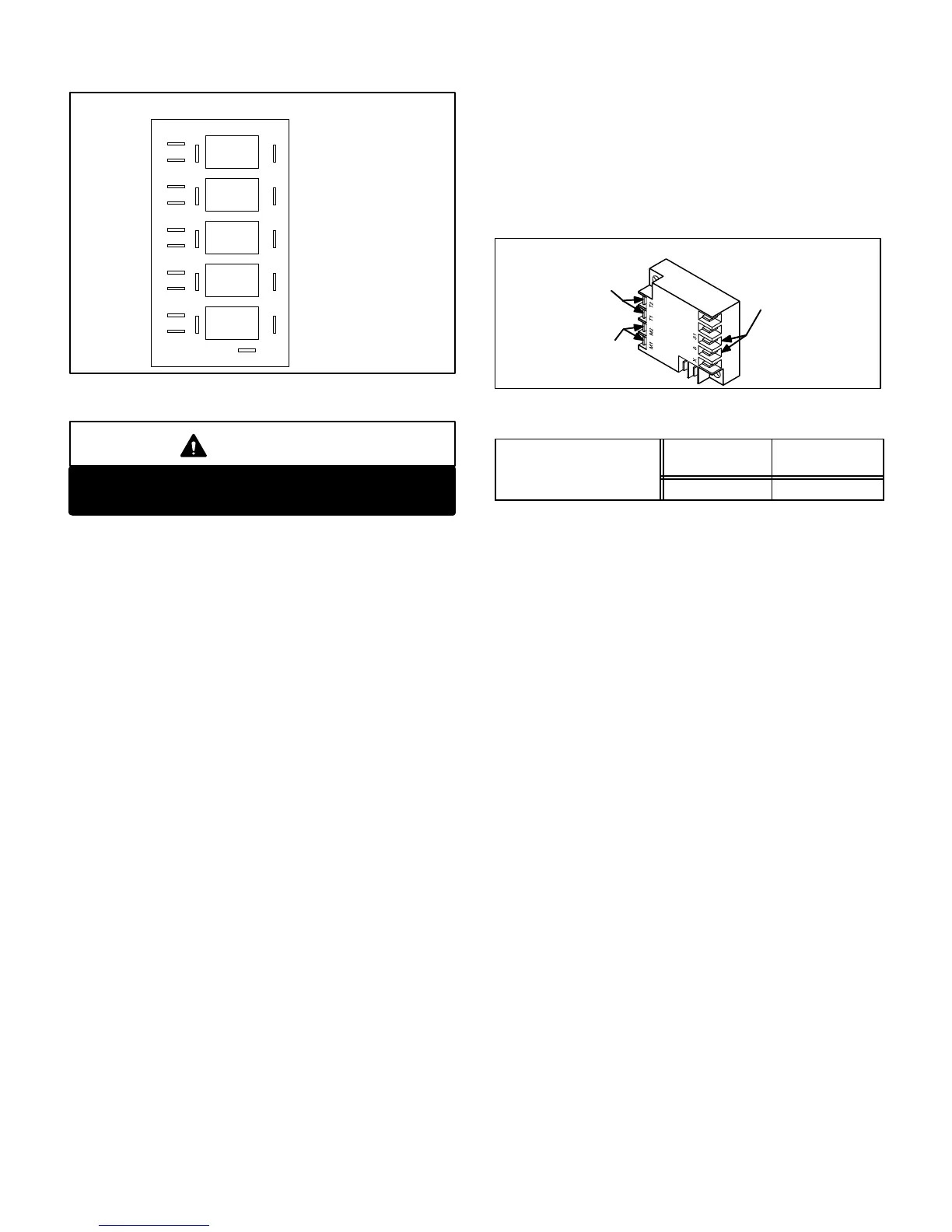

COIL COIL COIL COIL COIL

GW1W2Y2Y1

K46 K77 K49 K67 K66

CC CCC

GND

NO NO NO NO NO NCNCNCNCNC

PILOT RELAY BOARD A11

BLOWER

PILOT

1st STAGE

HEATPILOT

2nd STAGE

HEAT PILOT

2nd STAGE

COOL PILOT

1st STAGE

COOL PILOT

FIGURE 12

WARNING

Do not remove or bypass the pilot relay board.

Control damage or failure could result.

19- Low Ambient Lockout Switch

(Compressor Monitor) S3 (all units)

CHA16 units are equipped with a single compressor moni

tor located in the unit control box. The compressor monitor

is a SPST bimetal thermostat which opens on a tempera

ture drop. It is connected inline with the 24VAC compres

sor control circuits. When outdoor temperature drops be

low 40°F the compressor monitor opens to electrically dis

connect all compressors. When the compressors are dis

connected, cooling demand is handled by optional

REMD16 economizer (if installed). The monitor automati

cally resets when outdoor temperature rises above 50°F.

NOTE-Compressor monitors must be disconnected if

optional low ambient kit is used.

20- Low Ambient Lockout Switch

(Compressor Monitor) S30

(1353, 1603 only)

CHA161353 and 1603 (10 and 12.5 ton) units are

equipped with a second compressor monitor (S30) used in

addition to compressor monitor S3. S3 is identical to S30.

In units equipped with two compressor monitors, S3 pro

tects the first stage compressors and S30 protects the

second stage compressors.

21-Compressor Motor Protector A9, A10

(2553, 2753, 3003 only)

Motor protectors A9 and A10 are used in all CHA16 18.5

ton and larger units to provide compressor overtempera

ture sensing which helps protect the compressors. Com

pressors in these units have thermistors imbedded in the

motor windings. The motor protectors monitor the sensors

in each compressor and shuts off the compressor when

resistance increases above a preset limit. As the compres

sor windings cool, the resistance through the sensors

drops and the control resets. Table 2 shows the resistance

values for the winding temperature sensors.

FIGURE 13

COMPRESSOR PROTECTOR A9, A10

TO

COMPRESSOR

SENSORS

24VAC POWER

IN SERIES WITH

CONTACTOR COIL

TABLE 2

Compressor Winding

Trip Ohms

Temp. Rise

Reset Ohms

Tem. Fall

Temperature Sensor

16K to 24K 5.5K to 6.9K

C-Cooling Components

Summary of Features

CHA16 series units use independent cooling circuits consist

ing of separate compressors, condenser coils and evapora

tor coils. See figures 14, 15, 16, 17 and 18. See figure 16 for

CHA161853 vapor circuitry and

figure 17 for CHA161853 liquid circuitry. A draw-through type

condenser fan is used in all units. CHA16823, 953 units use

a single fan. All other units use two. All units are equipped with

a single belt drive blower that draws air across the evaporator

during unit operation.

On all units cooling may also be supplemented by field

installed economizer. The evaporators are slab type and are

stacked as shown in figures 19, 20 and 21. Each evaporator

uses a thermostatic expansion valve as the primary expan

sion device. Each evaporator is also equipped with enhanced

fins and rifled tubing. CHA161853 units are equipped with

two condenser coils split into three independent circuits.

Compressor 1 uses an independent circuit in the right con

denser coil, compressor 2 uses an independent circuit in the

left condenser coil and compressor 3 uses an independent

circuit split between the left and right condenser coils. See fig

ures 17and 20. In all units each compressor is protected by a

crankcase heater, high pressure switch and loss of charge

switch. Additional protection is provided by factory installed

low ambient thermostat (unit control box) and freezestats (on

each evaporator). Each cooling circuit is equipped with a ther

mometer well for charging.

Loading...

Loading...