Preface and general information

System block introduction

Signal types and scaling

1

27

EDBCSXA064 EN 3.2

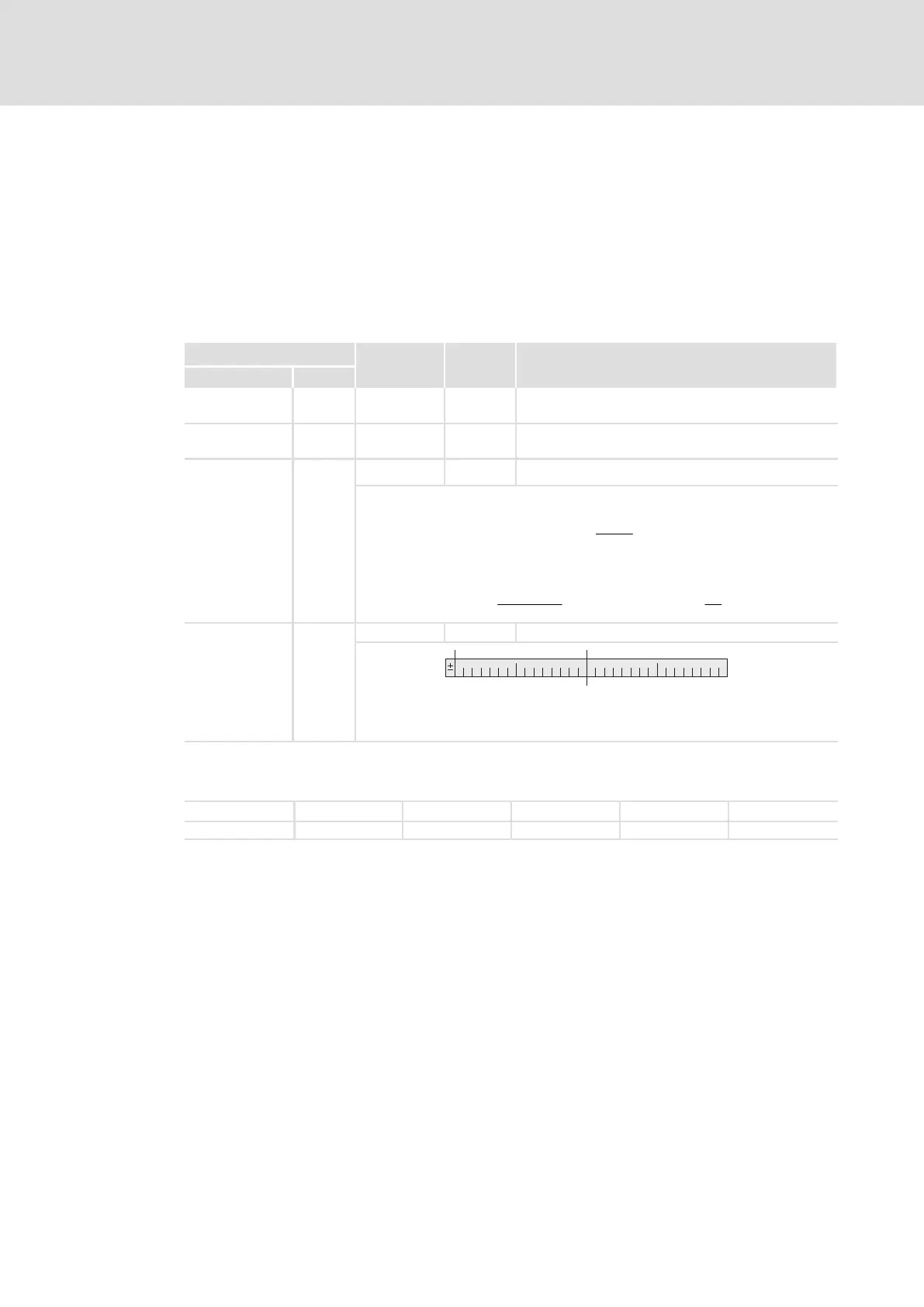

1.5.7 Signal types and scaling

A signal type can be assigned to most inputs and outputs of the Lenze function

blocks/system blocks. The following signal types are distinguished:

ƒ digital and analog signals

ƒ position and speed signals

The identifier of the corresponding input/output variable has an ending (starting with an

underscore). It indicates the signal type.

Signal

Ending Memory

Scaling

(external size º internal size)

Type Symbol

Analog _a (analog) 16 Bit1 100 % º 16384

Digital _b (binary) 1 bit 0 º FALSE; 1 º TRUE

Angular

difference or

speed (rot.)

_v (velocity) 16 Bit1 15000 rpm º 16384

l Angular difference/speed ref. to 1 ms

l Normalisation example:

1 motor revolution + 65536 [inc]

Variable value (..._v) +

15000

60000 [ms]

@ 65536 [inc] + 16384

ƪ

inc

ms

ƫ

Speed (on motor side) + 15000 [rpm] +

15000

60 [s]

Angle or position

_p (position) 32 Bit 1 motor revolution º 65536

High Word Low Word 031

Direction (0 º clockwise rotation; 1 º counter−clockwise rotation)

No. of motor revolutions (0 ... 32767)

Angle or position (0 ... 65535)

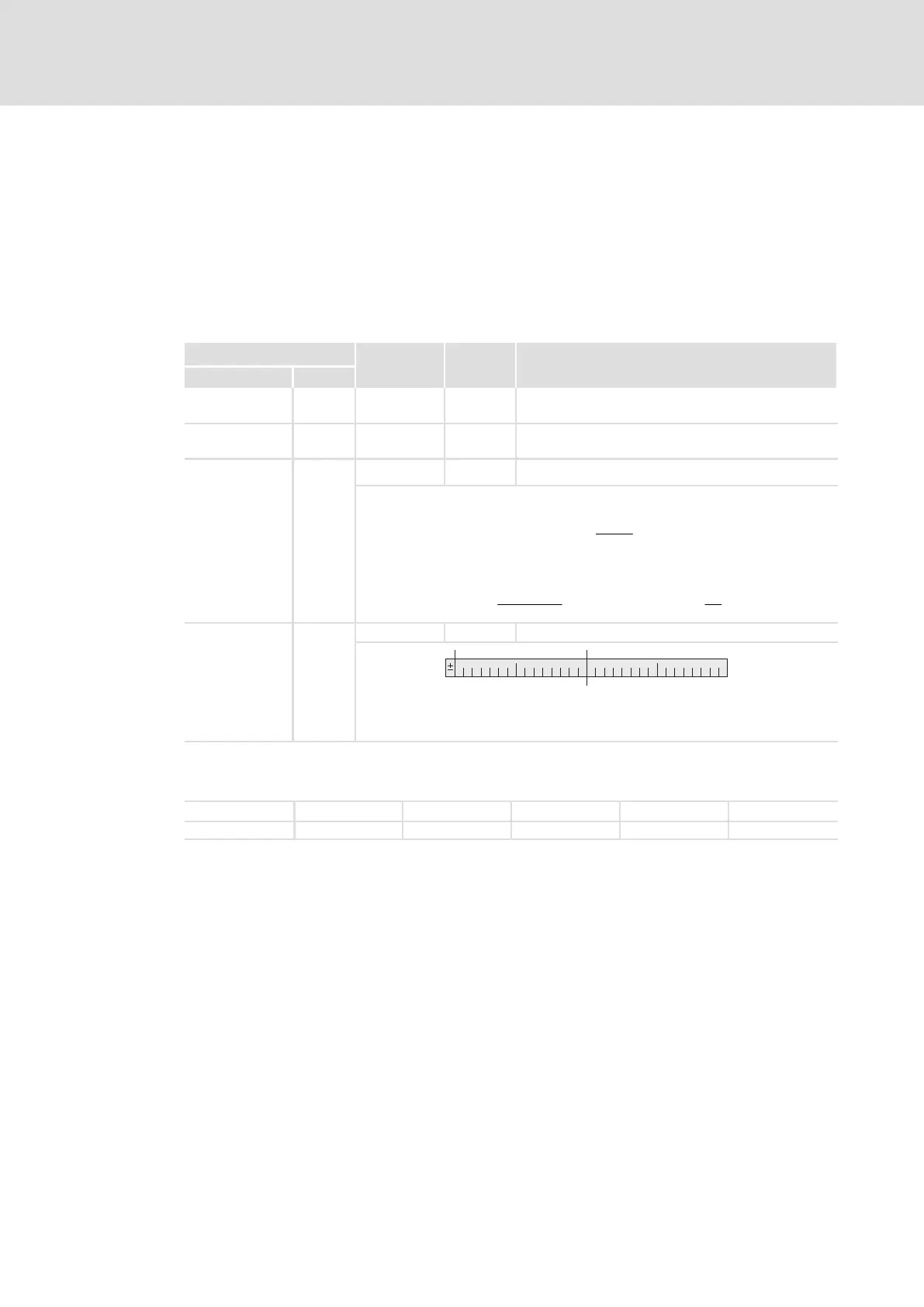

Due to their scaling, analog signals have an asymmetrical resolution range

(−200 % ... +199.99 %):

External: −200 % −100 % 0 % +100 % +199.99 %

Internal: −32768 −16384 0 +16384 +32767

Loading...

Loading...