Electrical installaon

Operang Instrucons i550 protec10

6 Electricalinstallaon

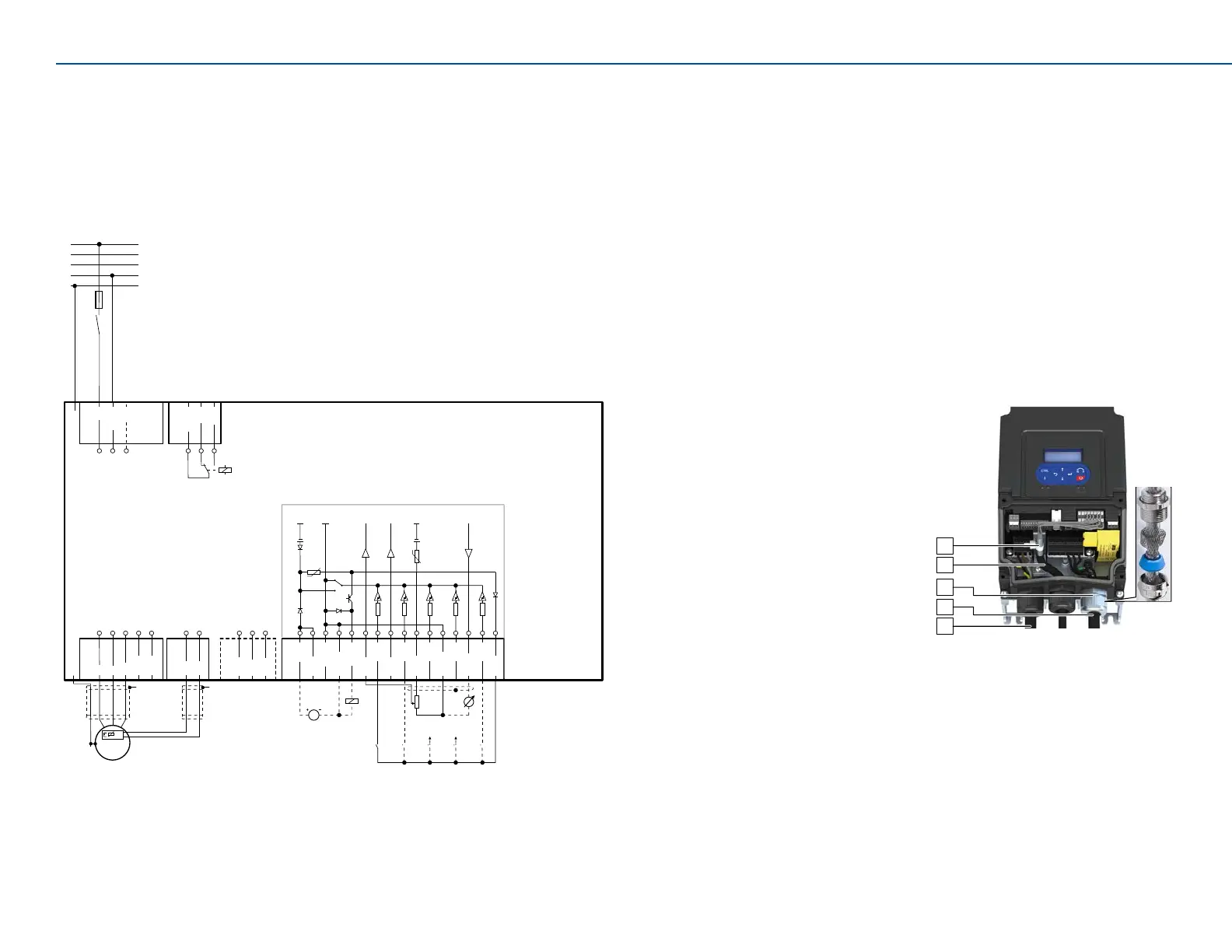

6.1 Generaloverviewoftheconnecons

The connecon diagram is considered exemplary for all voltage and

power classes.

Deviang mains connecon diagrams can be found in the corresponding

chapters.

X1

SIA

GS

SIB

DC 24 V SELV/PELV

(+19.2 … +28.8 V)

"

1k ... 10k

0 ... 10 V

S1

DI3 DI4

100 mA

4.4k

+24 V +10 V

4.4k

4.4k

4.4k

4.4k

10 mA

GND

DO1

DI1

DI2

DI3

DI4

DI5

24E

GND

AI1

AI2

10V

GND

AO1

24V

24E

X3

X105

U

V

W

Rb1

Rb2

+

X109

T1

T2

""

M

3~

+

J

J

NC

NO

COM

X9

AC 240 V

3 A

+

F1

Q1

X100

L1

L2/N

1/N/PE

AC 170 V ... 264 V

45 Hz ... 65 Hz

PE

N

L3

L2

L1

3/N/PE

AC 480 V

L3

Motor connecon

PTC or

thermal

contact

Safety STO

Control terminals

Mains connecon

Relay output

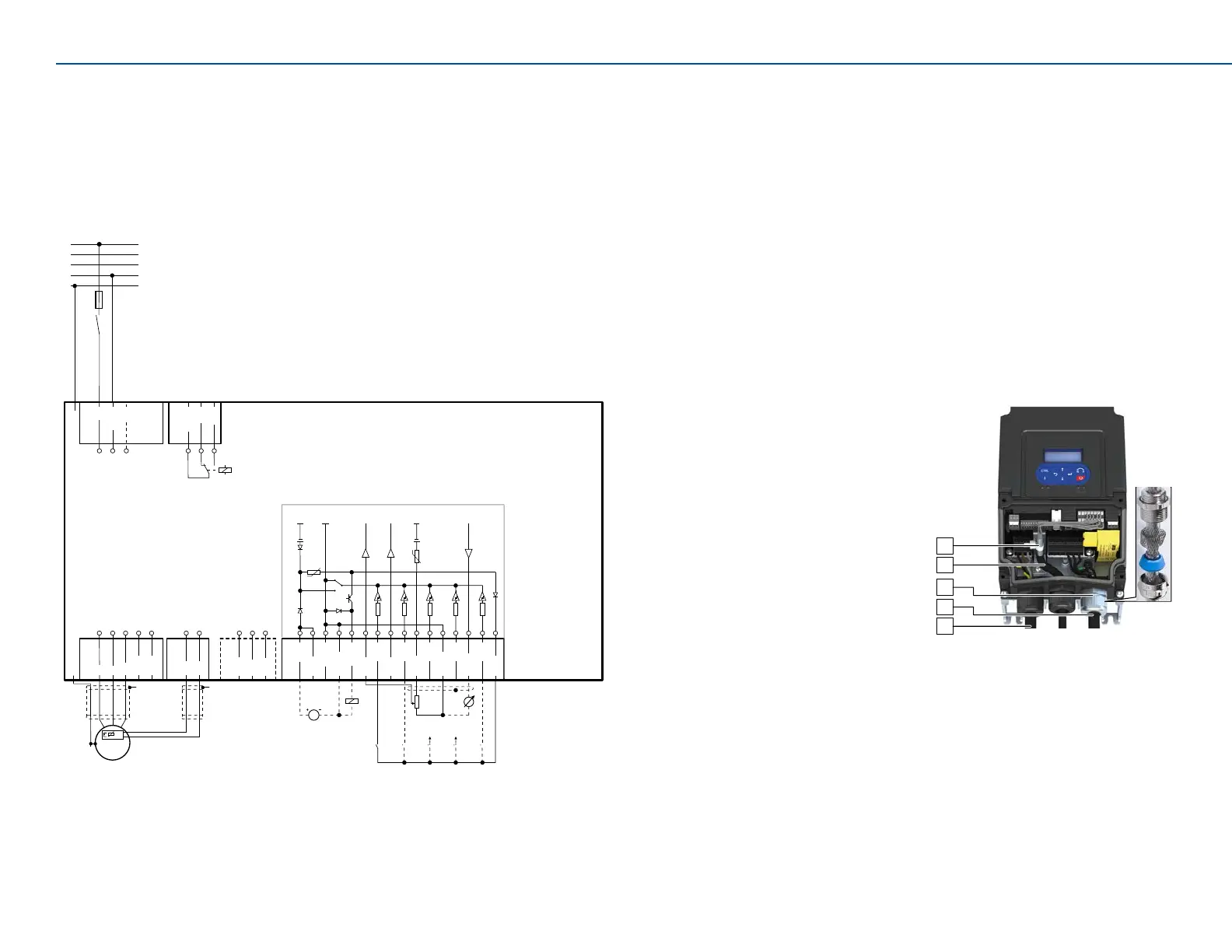

A Shield connecon for control

connecons

A

B

C

D

E

B Control cable

C EMC cable gland

D Low-capacitance motor cable

(C-core/core/C-core/shield

< 75/150 pF/m ≥ AWG 14;

C-core/core/C-core/shield

< 150/300 pF/m ≤ AWG 12)

E Power supply

6.2 EMC-compliantinstallaon

The drive system of inverter and drive meet the EMC Direcve

2014/30/EU if they are installed according to the guidelines of CE-typical

drive systems. These guidelines should also be followed in installaons

requiring FCC Part 15 or ICES 001 compliance.

The structure of the installaon place must support the EMC-compliant

installaon with shielded motor cables.

• Please use suciently conducve shield connecons.

• Connect the housing with shielding eect to the grounded mounng

plate with a surface as large as possible, e.g. of inverters and RFI

lters.

• Use central earthing points.

The following example shows the eecve wiring.

Loading...

Loading...