§

C)

=

II)

.:-

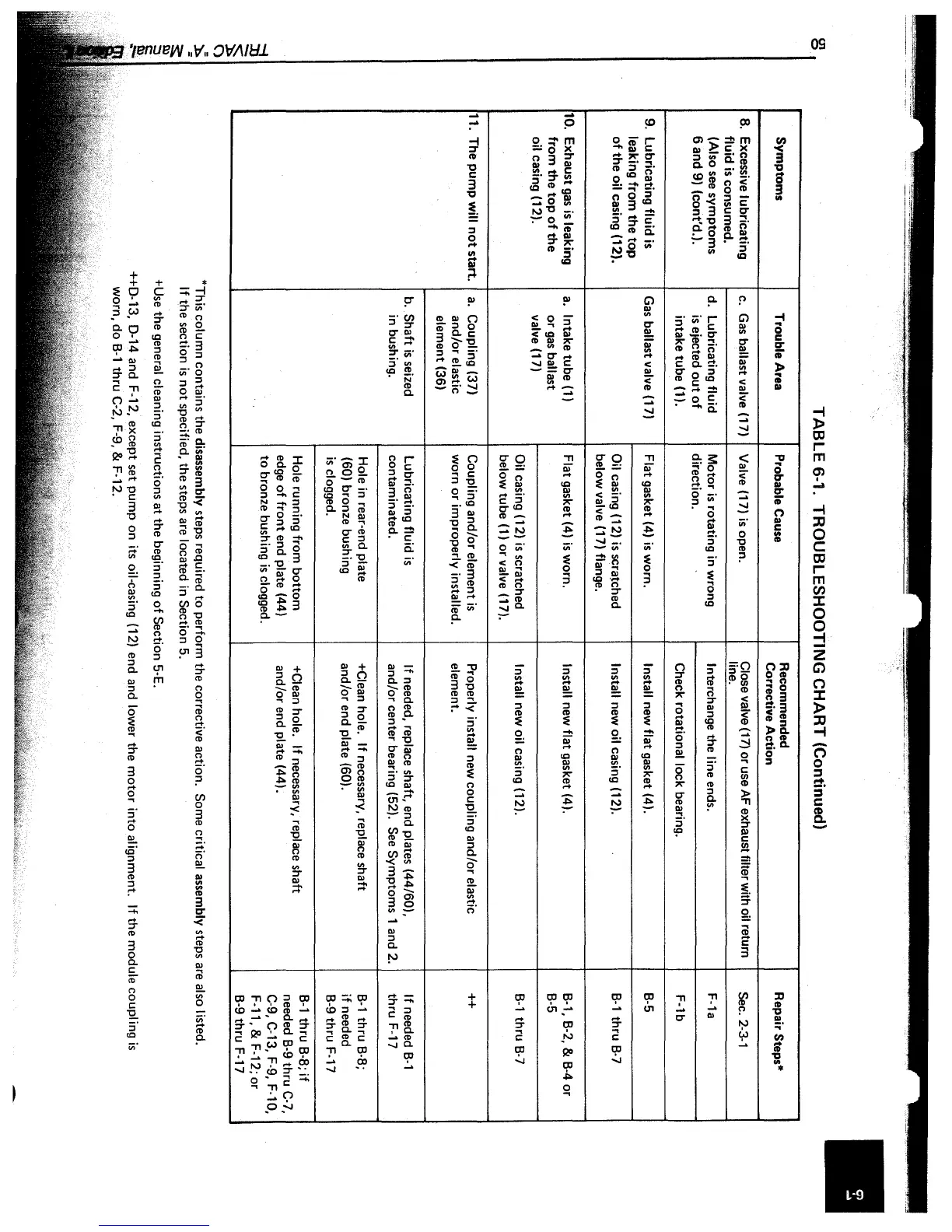

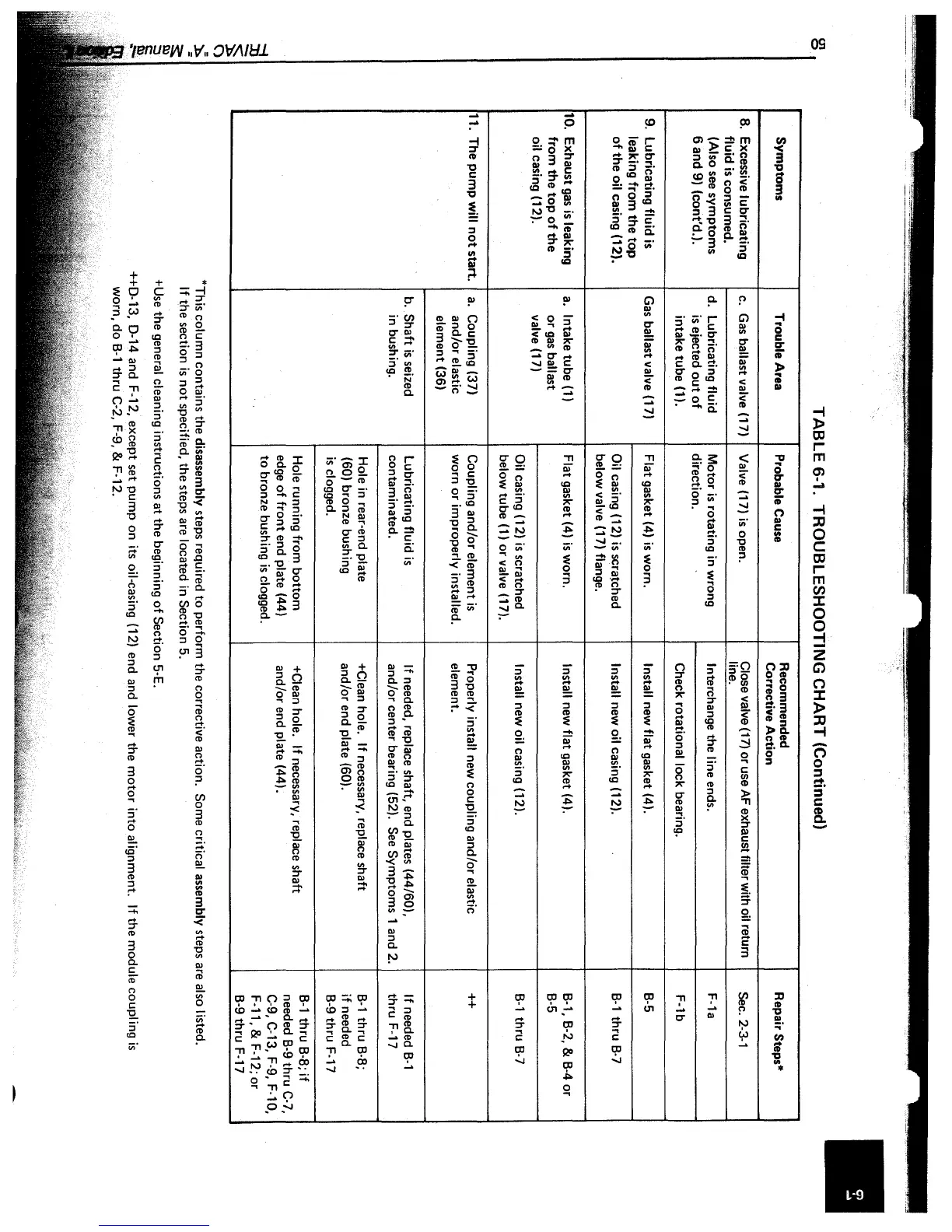

TABLE

6-1. TROUBLESHOOT1NG CHART (Continued)

Symptoms

Trouble Area

Probable Cause

Recommended

Repair Steps*

Corrective Action

8. Excessive

lubricating

c. Gas ballast valve (17)

Valve (17)

is

open.

Close valve

(17)

or use

AF

exhaust filter

with

oil

return

Sec.

2-3-1

fluid

is

consumed.

line.

(Also

see

symptoms

d. Lubricating fluid

Motor

is

rotating in wrong

Interchange the line ends.

F-la

6 and 9) (cont'd.).

is

ejected

out

of

direction.

intake

tube

(1). Check rotational lock bearing.

F-lb

9. Lubricating fluid

is

Gas ballast valve (17) Flat gasket (4)

is

worn.

Install new flat gasket (4).

8-5

leaking from the

top

of

the

oil casing (12).

Oil

casing (12)

is

scratched Install new

oil

casing (12).

8-1

thru 8-7

below valve (17) flange.

10.

Exhaust gas

is

leaking

a. Intake

tube

(1)

Flat gasket (4)

is

worn.

Install new flat gasket (4).

8-1,8-2,

& 8-4 or

from

the

top

of

the

or

gas

ballast 8-5

oil casing (12).

valve (17)

Oil

casing (12)

is

scratched Install new oil casing (12).

8-1

thru 8-7

below

tube

(1) or valve (17).

11. The

pump

will

not

start.

a.

Coupling (37)

Coupling

and/or

element

is

Properly install new coupling and/or elastic

++

and/or

elastic worn

or

improperly installed.

element.

element

(36)

b.

Shaft

is

seized Lubricating fluid

is

If

needed, replace shaft, end plates (44/60),

If

needed

8-1

in

bushing. contaminated.

and/or center bearing (52).

See Symptoms 1 and 2. thru F-17

Hole

in

rear-end plate

+Clean hole.

If

necessary, replace shaft

8-1

thru 8-8;

(60) bronze bushing

and/or end

plate (60).

if needed

is

clogged.

8-9 thru F-17

Hole running from

bottom

+Clean hole.

If

necessary, replace shaft

8-1

thru 8-8;

if

edge

of

front end plate (44)

and/or end

plate (44).

needed 8-9 thru

C-7,

to

bronze bushing

is

clogged.

C-9, C-13, F-9, F-10,

F-l1,&F-12;or

8-9 thru F-17

----

*This column contains the disassembly steps required

to

perform the corrective action. Some critical assembly steps are also listed.

If

the section

is

not

specified,

the

steps are located

in

Section 5.

+Use

the

general cleaning instructions

at

the

beginning

of

Section 5-E.

++D-13, D-14 and F-12, except set

pump

on its oil-casing (12) end and lower

the

motor

into alignment.

If

the module coupl

ing

is

worn,

do

8-1

thru C-2, F-9, & F-12.

Loading...

Loading...