l1

§

()

:a;

§

g:

:::s

,...

(11

....

.,

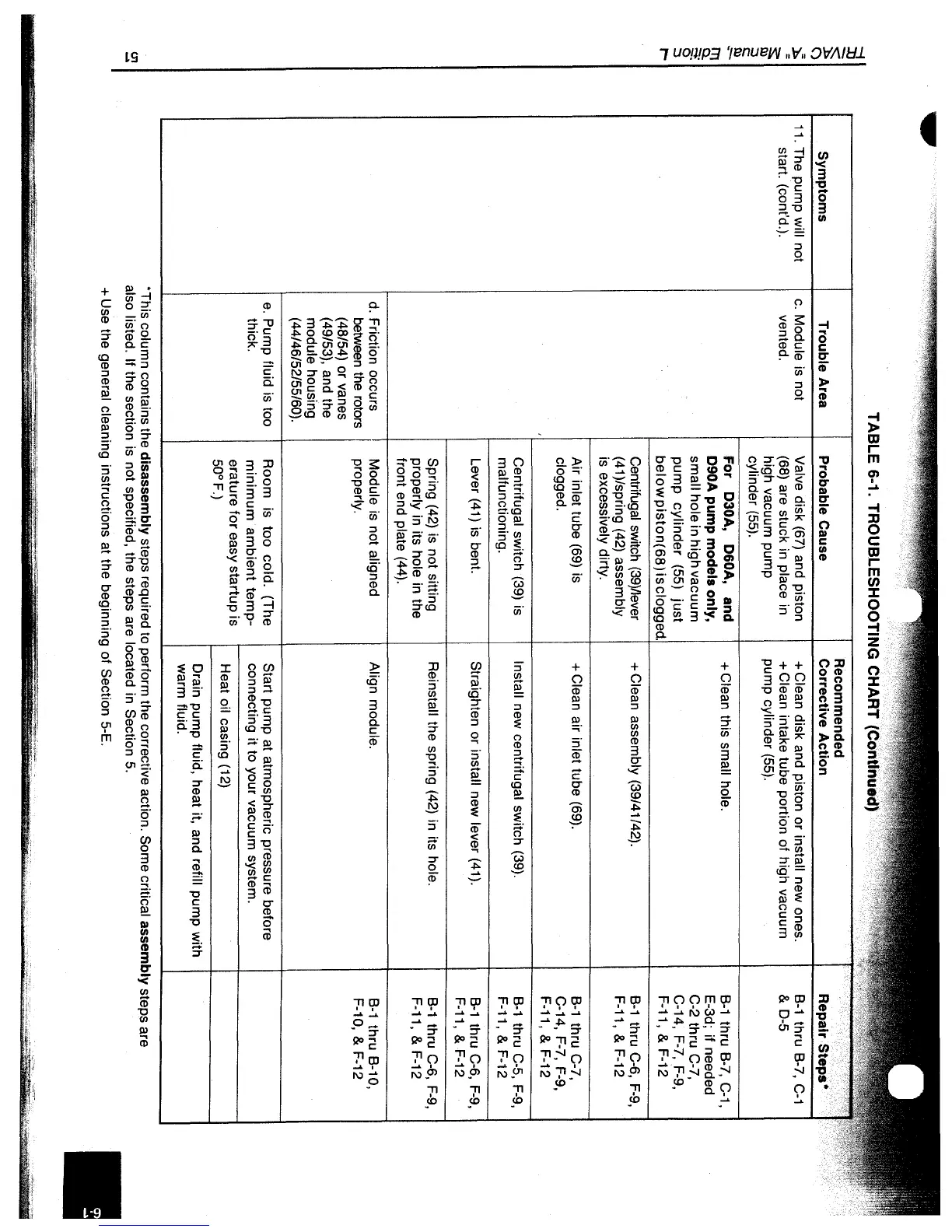

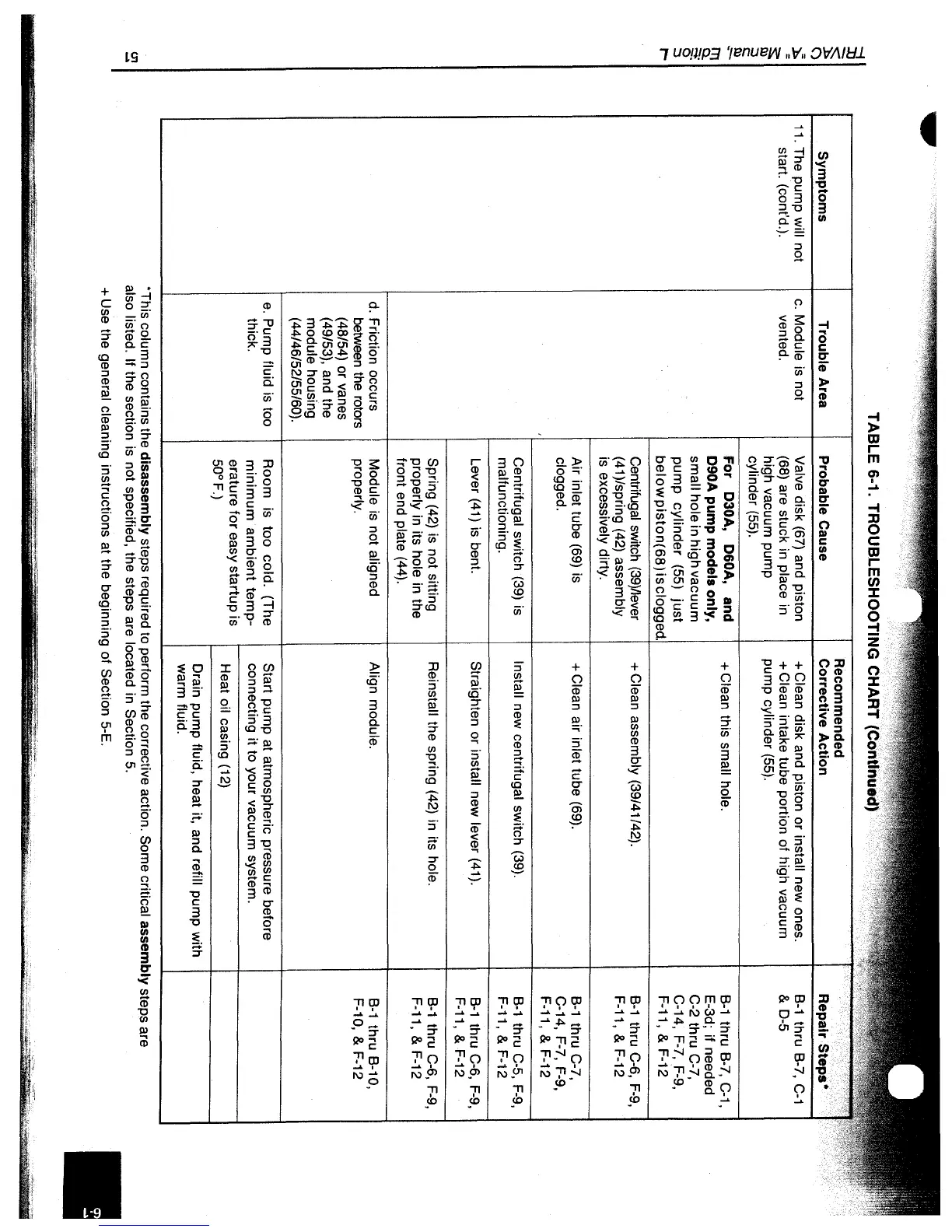

Symptoms

11.

The pump will not

start. (cont'd.).

TABLE 6-1. TROUBLESHOOTING CHART ,"' .......... .

Trouble Area

c.

Module is not

vented.

d.

Friction occurs

between

the

rotors

(48/54) or vanes

(49/53), and the

module housing

(44/46/52/55/60) .

e.

Pump fluid is too

thick.

Probable Cause

Valve disk

(67)

and piston

(68) are stuck in place in

high vacuum pump

cylinder

(55).

For D30A, D60A, and

D90A pump models only,

small hole in high vacuum

pump

cylinder

(55)

just

below

piston(68)

isclogg

Centrifugal switch

(39)/Iever

(41

)/spring

(42)

assembly

is excessively dirty.

Air inlet tube

(69)

is

clogged.

Centrifugal switch (39) is

malfunctioning.

Lever

(41)

is bent.

Spring

(42)

is not sitting

properly in its hole in the

front end plate (44).

Module

is

not aligned

properly.

Room is too cold. (The

minimum

ambient

temp-

erature

for

easy startup is

50°F.)

+ Clean disk and piston or install new ones.

+ Clean intake tube portion of high vacuum

pump cylinder (55).

+ Clean this small hole.

+ Clean assembly (39/41142).

+ Clean air inlet tube (69).

Install new centrifugal switch (39).

Straighten or

install new lever (41).

Reinstall the spring (42) in its hole.

Align module.

Start pump

at

atmospheric pressure before

connecting it to your vacuum system.

Heat oil casing (12)

Drain pump fluid, heat it, and

refill pump with

warm fluid.

Repair

B-1

thru B-7,

C-1

&

0-5

B-1

thru B-7, C-1,

E-3d; if needed

C-2 thru

Co?,

C-14, F-?, F-9,

F-11, & F-12

B-1

thru C-6,

F-9,

F-11, & F-12

B-1

thru

Co?,

C-14, F-?, F-9,

F-11,&F-12

B-1

thru C-5, F-9,

F-11, & F-12

B-1

thru C-6,

F-9,

F-11, & F-12

B-1

thru C-6,

F-9,

F-11, & F-12

B-1

thru B-10,

F-10, & F-12

·This

column contains the disassembly steps required to perform the corrective action. Some critical assembly steps are

also listed.

If the section is not specified, the steps are located in Section 5 .

+ Use the general cleaning instructions at the beginning of Section 5-E.

Loading...

Loading...