:ti

§

()

:b

=

:::s

fij

.:-

Symptoms

12.

The

pump

will

not

achieve its rated

pumping speed. (See

Section 1

of

the

Leybold-Heraeus

Catalog for pumping

speed curves.)

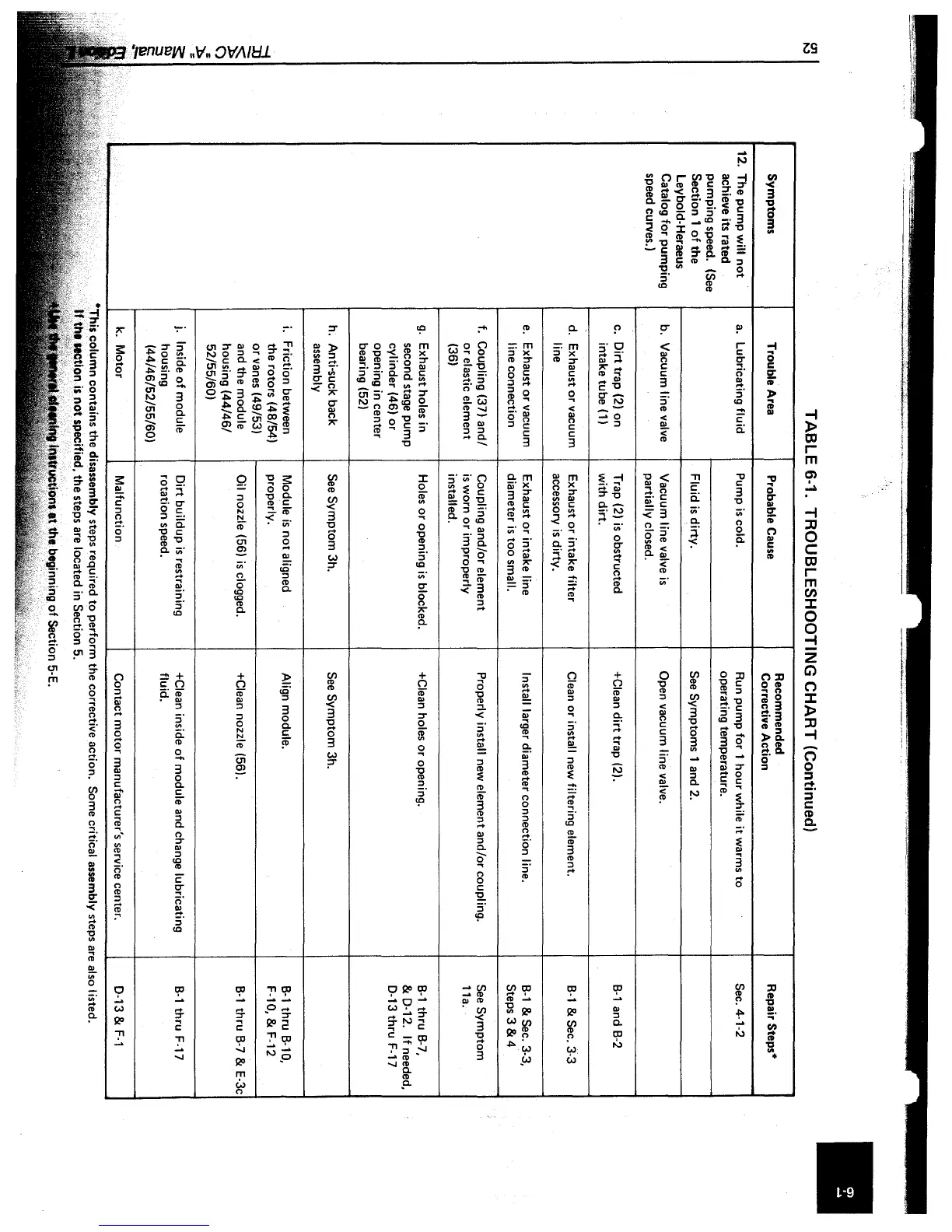

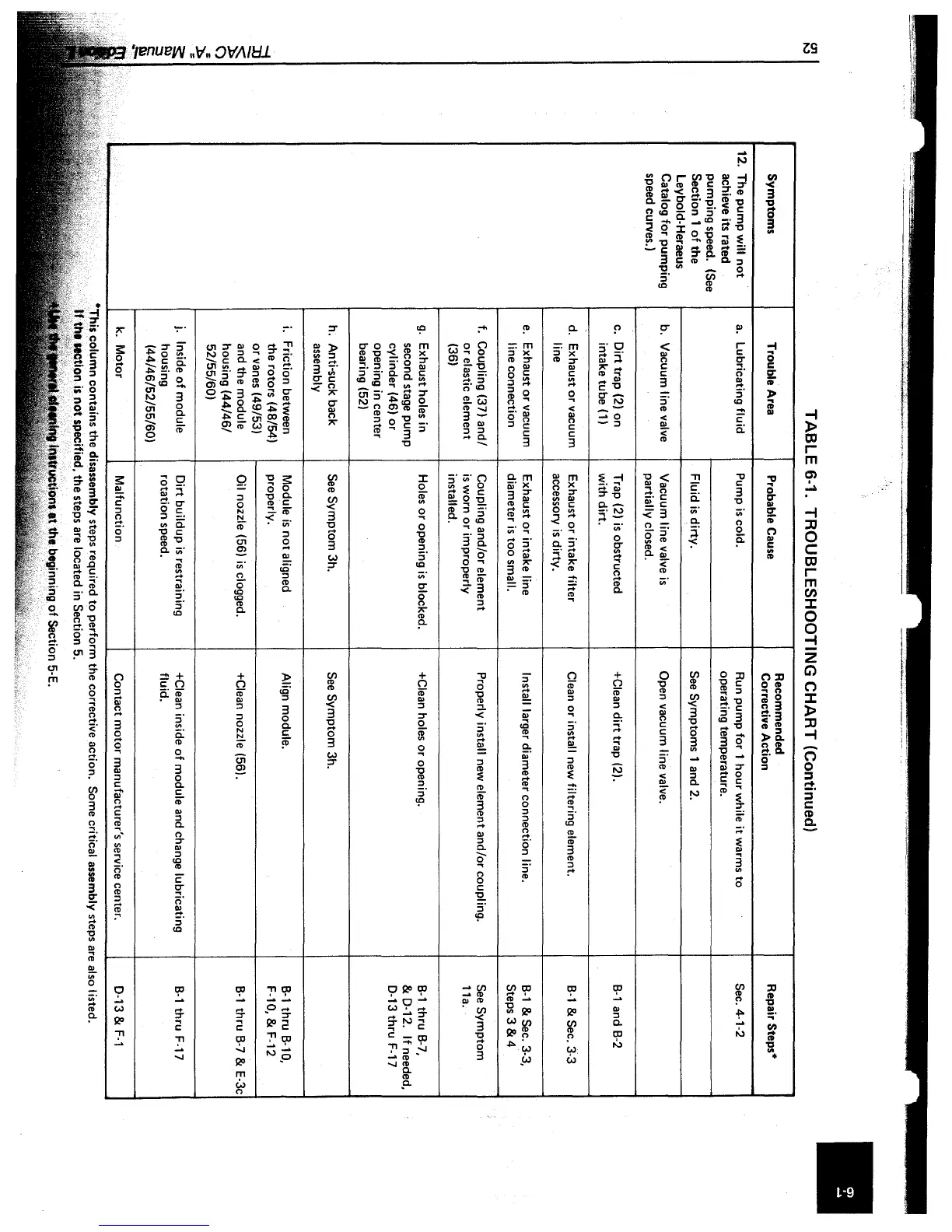

TABLE

6-1.

TROUBLESHOOTING

CHART

(Continued)

Trouble Area

Probable Cause

Recommended

Repair Steps*

Corrective Action

a. Lubricating fluid

Pump

is

cold.

Run pump for 1 hour while it warms

to

Sec. 4-1-2

operating temperature.

Fluid

is

dirty.

See Symptoms 1 and 2.

b. Vacuum

line valve

Vacuum line valve

is

Open vacuum line valve.

partially

closed.

c. Dirt trap (2) on

Trap (2)

is

obstructed

+Clean dirt trap (2).

B-1

and

B-2

intake

tube

(1)

with dirt.

d. Exhaust

or

vacuum

Exhaust

or

intake filter

Clean

or install new filtering element.

B-1

& Sec. 3-3

line

accessory

is

dirty.

e.

Exhaust

or

vacuum

Exhaust

or

intake line

Install larger

diameter connection line.

B-1

& Sec. 3-3,

line

connection

diameter

is

too

small.

Steps

3 & 4

f.

Coupling (37)

and/

Coupling

and/or

element

Properly install

new element and/or coupling.

See Symptom

or

elastic element

is

worn

or

improperly

lla.

(36)

installed.

g.

Exhaust holes

in

Holes

or

opening

is

blocked.

+Clean holes

or

opening.

B-1

thru

B-7,

second stage pump

& 0-12.

If

needed,

cylinder (46)

or

0-13

thru F-17

opening

in

center

bearing (52)

h. Anti-suck back

See Symptom 3h.

See Symptom 3h.

assembly

i. Friction between

Module

is

not

aligned

Align module.

B-1

thru

B-l0,

the rotors (48/54) properly.

F-10,

& F-12

or

vanes (49/53)

and

the

module

Oil

nozzle (56)

is

clogged.

+Clean nozzle

(56).

B-1

thru

B-7

&

E-3c

housing

(44/46/

52/55/60)

j. Inside

of

module

Dirt buildup

is

restraining

+Clean inside of module and change lubricating

B-1

thru

F-17

housing

rotation speed.

fluid.

(44/46/52/55/60)

k. Motor

Malfunction

Contact motor manufacturer's service center.

0-13&F-l

-'-

--------

---

----

--------

*This column contains the disassembly steps required

to

perform the corrective action. Some critical assembly steps are also listed.

Jfth.stetlon

is

not

specified, the steps are located

in

Section 5.

Loading...

Loading...