28

Lubrication Schedule

LFA recommends the following TDP 6s

®

parts to be lubricated according to the following

frequency:

Part Location Image Frequency Type of Lubricant

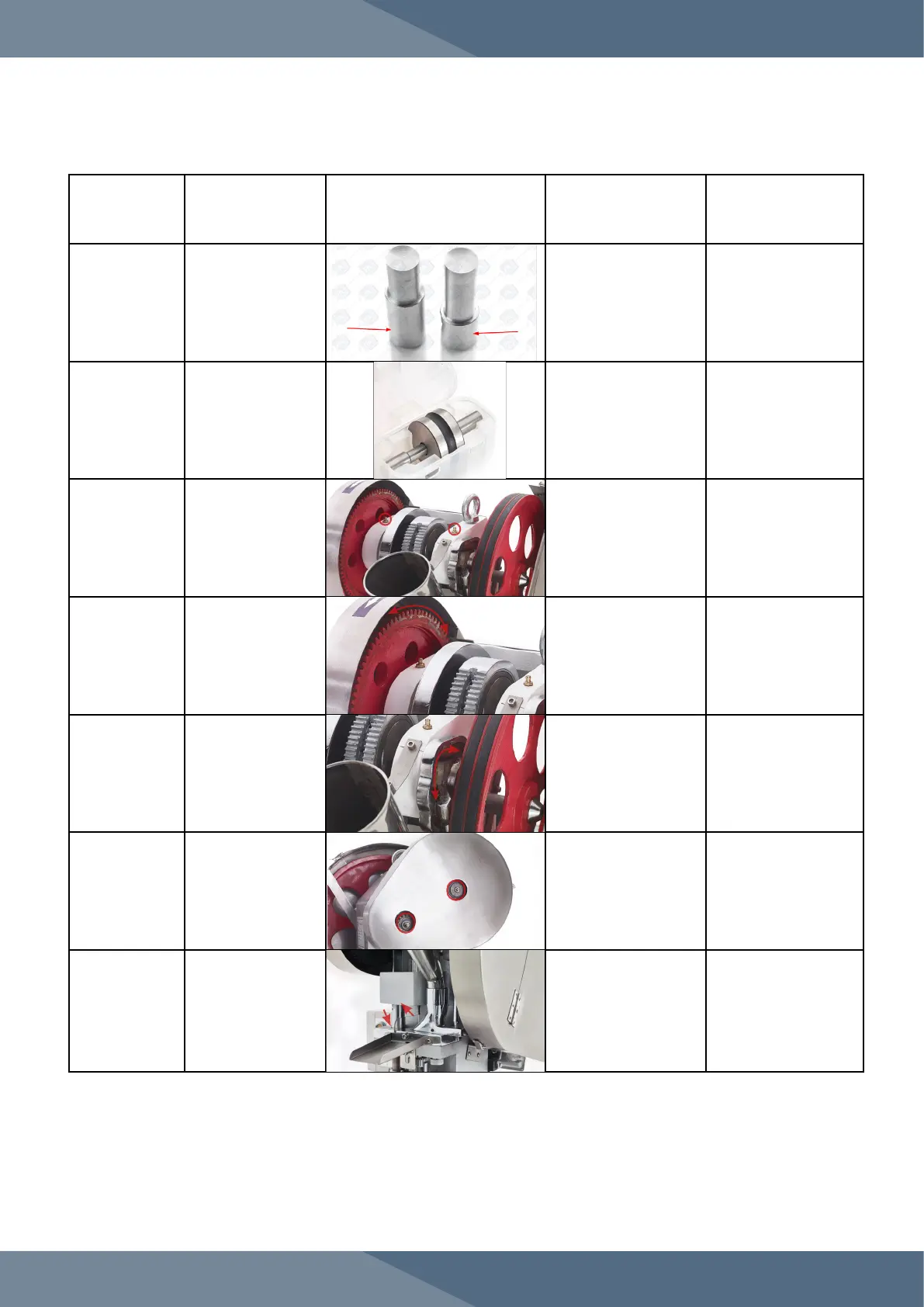

Tooling heads

The heads of the

Upper Punch and

Lower Punch

Visually inspect and

apply when dry

Assembly paste

Tooling (after

cleaning)

Storage container

Apply after cleaning Mineral oil

Top Cam Drive

Shaft

The topmost Grease

Nipples

Apply (a) after every

5000 tablets, (b) after a

deep clean, or (c) when

the press has not been

used for an extended

period of time

NLGI Grade 2

Cam Drive Cog Teeth on cog

Apply (a) after every

5000 tablets, (b) after a

deep clean, or (c) when

the press has not been

used for an extended

period of time

NLGI Grade 2

Boot Timing

Cam

Cam track and top of

Boot Timing Bar

Apply (a) after every

5000 tablets, (b) after a

deep clean, or (c) when

the press has not been

used for an extended

period of time

NLGI Grade 2

Pinion Gear and

Top Cam Drive

Shaft

Grease Nipples on

Cam Drive Cog and

Pinion Gear

Apply (a) after every

5000 tablets, (b) after a

deep clean, or (c) when

the press has not been

used for an extended

period of time

NLGI Grade 2

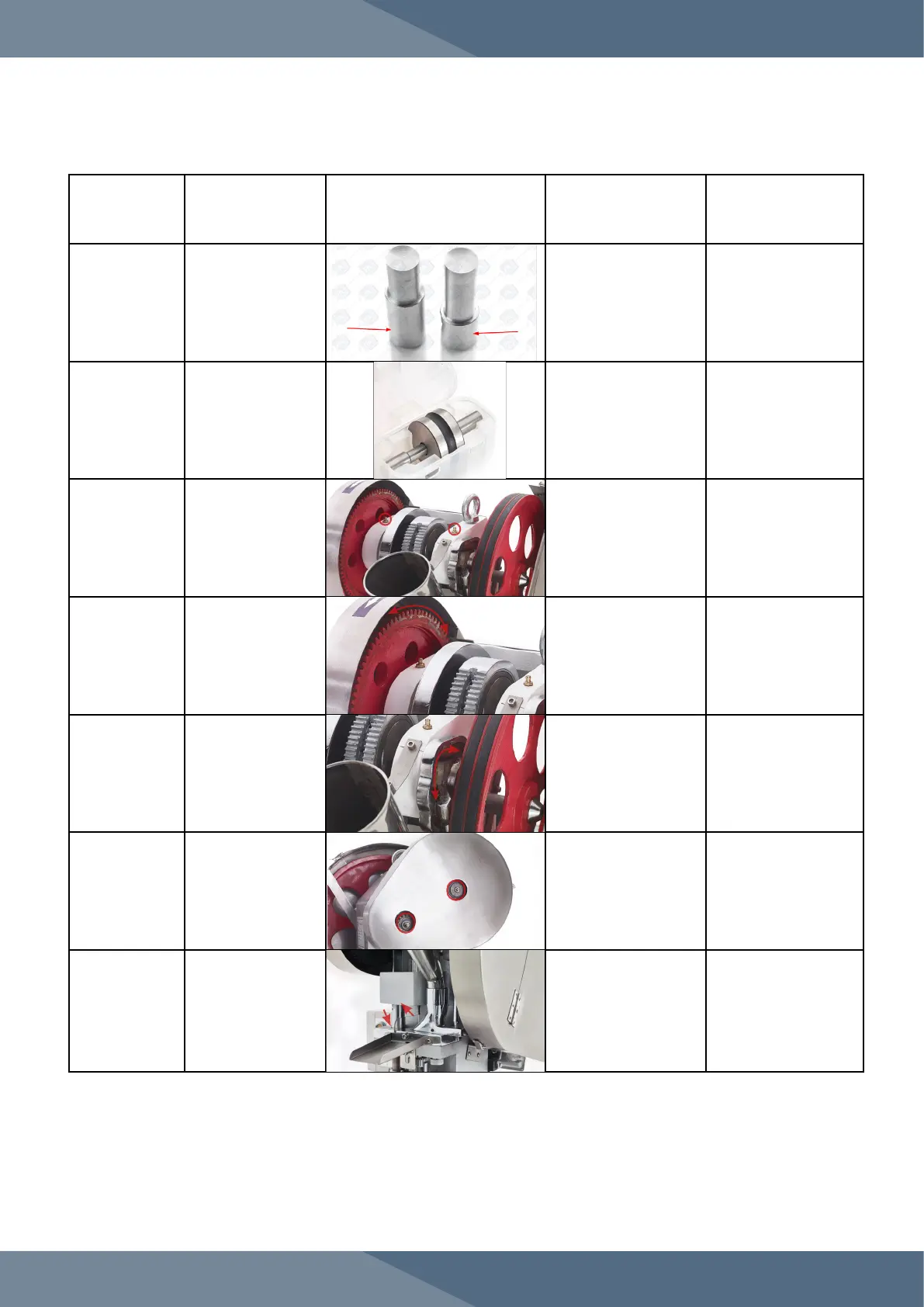

Lower Drift Pin

Assembly Timing

Rod

The points at which

the Lower Drift Pin

Assembly, Upper

Drift

Pin Assembly

Mounting Block, and

TDP 6s

®

Base meet.

Apply a small amount

whenever the press will

be left unattended for

an extended period of

time

Mineral oil

Loading...

Loading...