43

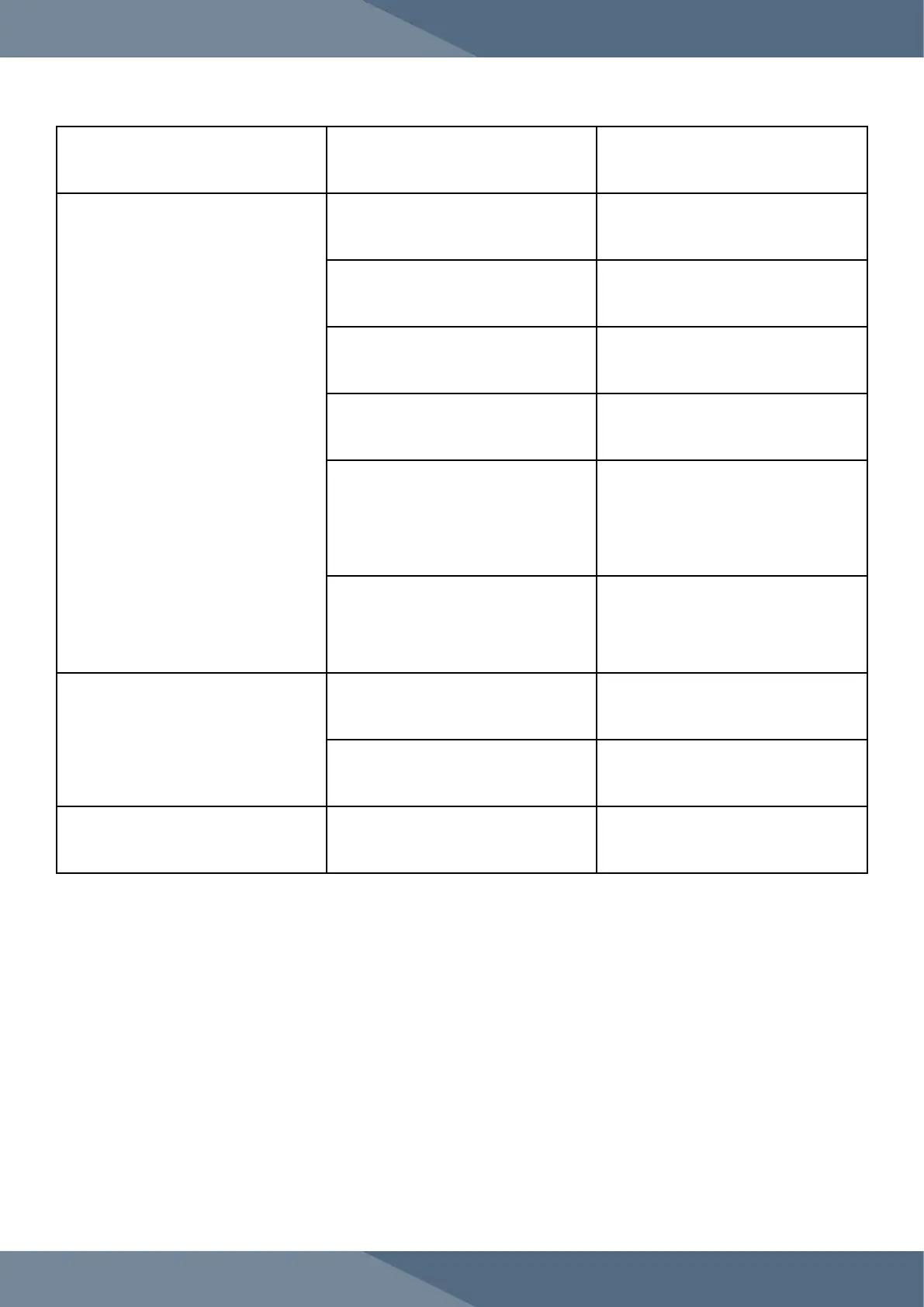

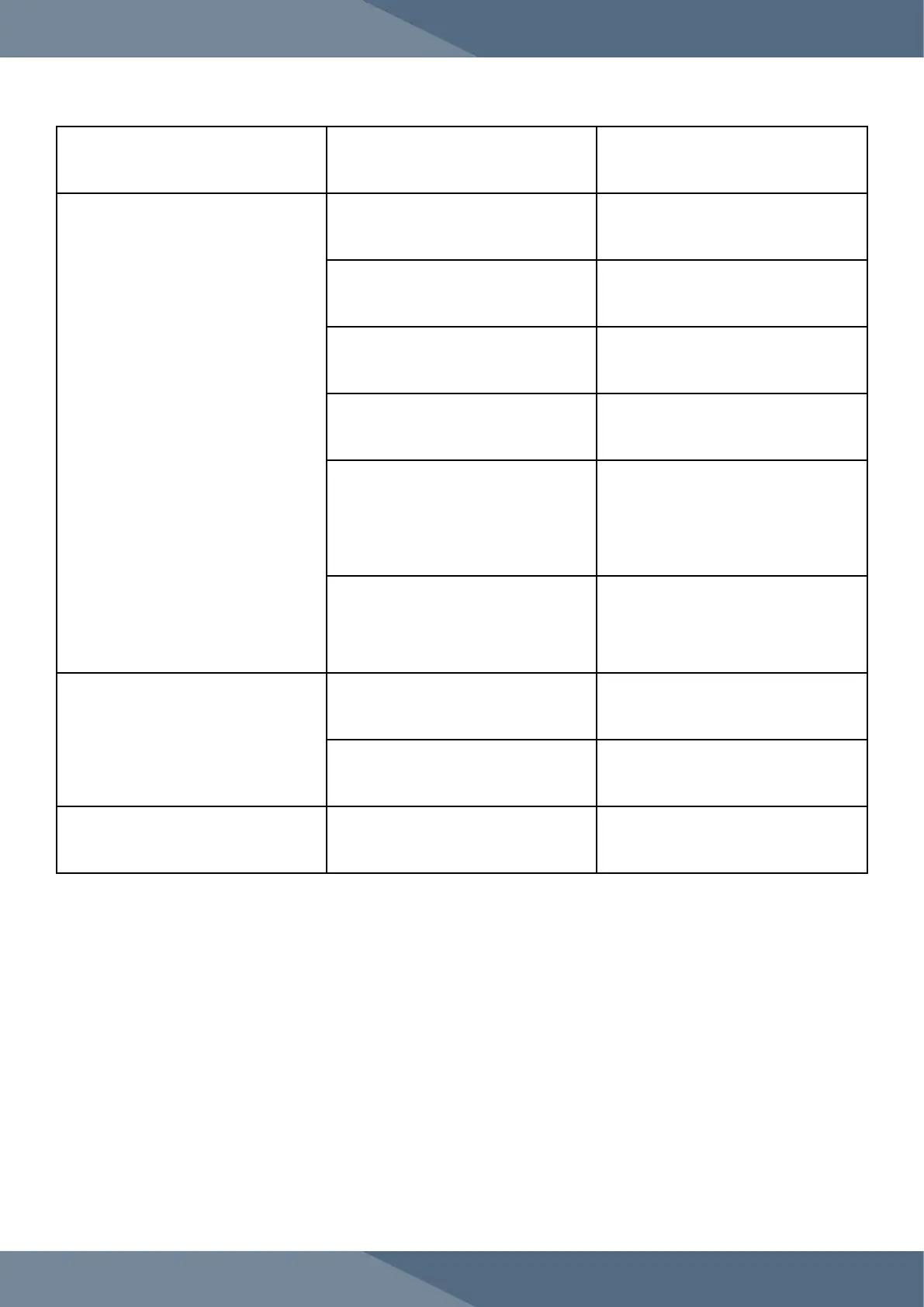

Symptom Possible Cause Possible Solution

Inability to compact materials to

tablet form

Boot is blocked and not enough

materials are flowing out.

Check the Boot for a potential clog.

The Boot Timing Bar is not secured.

Tighten the Boot Timing Bar's nuts

and bolt.

There is not enough pressure.

Move down the Pressure Adjustment

to lower the Upper Drift Pin Assembly

and increase the punch pressure.

The Lower Punch is broken.

Remove the Lower Drift Pin Assembly

to access the broken Lower Punch.

After removing it, replace the Tooling.

The Lower Drift Pin Assembly is not

dropping properly during filling.

Check that there is not a buildup of

powder between the Lower Punch

and the Die. Then check that the

Lower Drift Pin Assembly has enough

clearance to drop through the hole in

the base.

There are flowing issues with the mix.

If the machine is able to make tablets

with LFA's Firmapress

®

, then the

problem is your mix. Adjust your

formulation. If still an issue, contact

LFA for support.

Powder sticks to the Upper Punch

The punch pressure needs to be

adjusted.

Rotate the Upper Drift Pin Assembly

to adjust the punch pressure.

There may be an abnormality with the

machine.

Inspect the machine for damage and

contact LFA for support if needed.

Powder sticks to the Lower Punch There are issues with the mix.

Adjust your formulation. If still an

issue, contact LFA for support.

Loading...

Loading...